Damping vibration-attenuation and noise-reduction method as well as pored damping sheet

A technology of vibration reduction, noise reduction, and damping sheet, which is applied in the direction of sound-emitting devices, instruments, pipes/pipe joints/fittings, etc., can solve the problems of unknown performance such as the frequency range of vibration reduction, durability, and adaptability, etc., to achieve Effects of simple structure, weight reduction, material and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

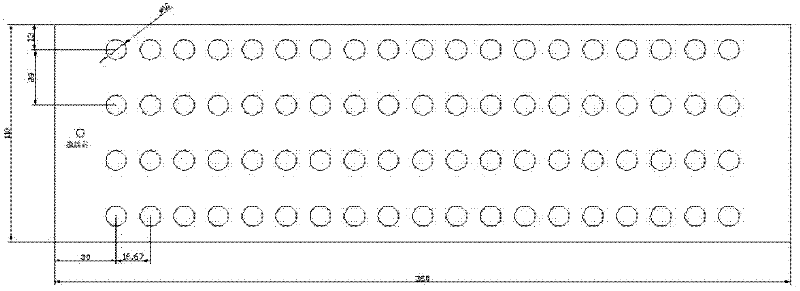

[0019] see figure 1 . In Example 1 of the present invention, a circular hole is opened on the sheet substrate, with a diameter of ф10 mm, a row spacing of 28 mm, and a column spacing of 6.67 mm. The damping sheet has four rows and nineteen columns of holes.

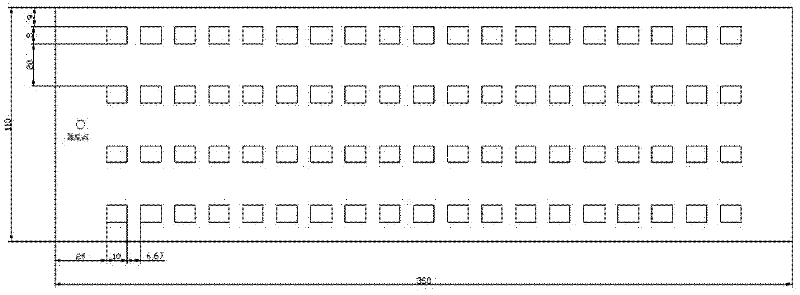

[0020] see figure 2 . In Example 2 of the present invention, a rectangular hole is opened on the sheet substrate, the hole size is 8×10, the row spacing is 28 mm, and the column spacing is 6.67 mm. The damping sheet has four rows and nineteen columns of holes.

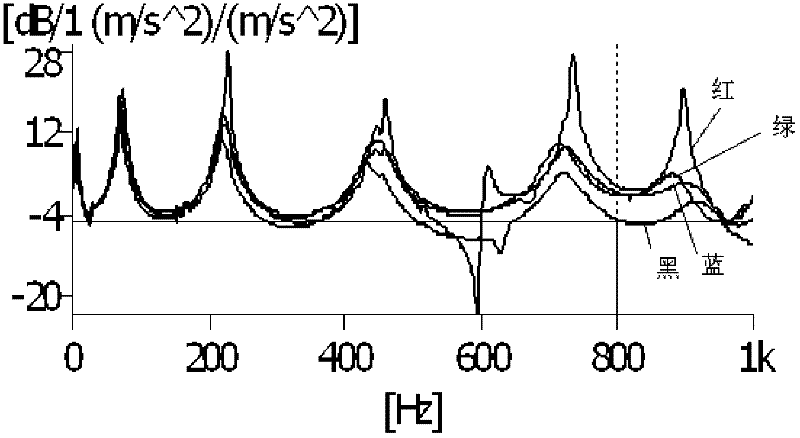

[0021] For comparison between Embodiments 1 and 2 of the present invention and the working conditions without damping and the working conditions with damping and no openings, see image 3 .

[0022] Paste round holes and rectangular structures on the pipeline, and the implementation effect diagrams of the opening rate of 3% and 30% are respectively shown in Figure 4 with Figure 5 .

[0023] In the vibration and noise reduction method of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com