Locking mechanism for molded resin component

A locking mechanism and molding technology, applied in the direction of fasteners, electrical components, parts of connecting devices, etc., can solve the problems of deformation of locking retention force or inability to display dimensional errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

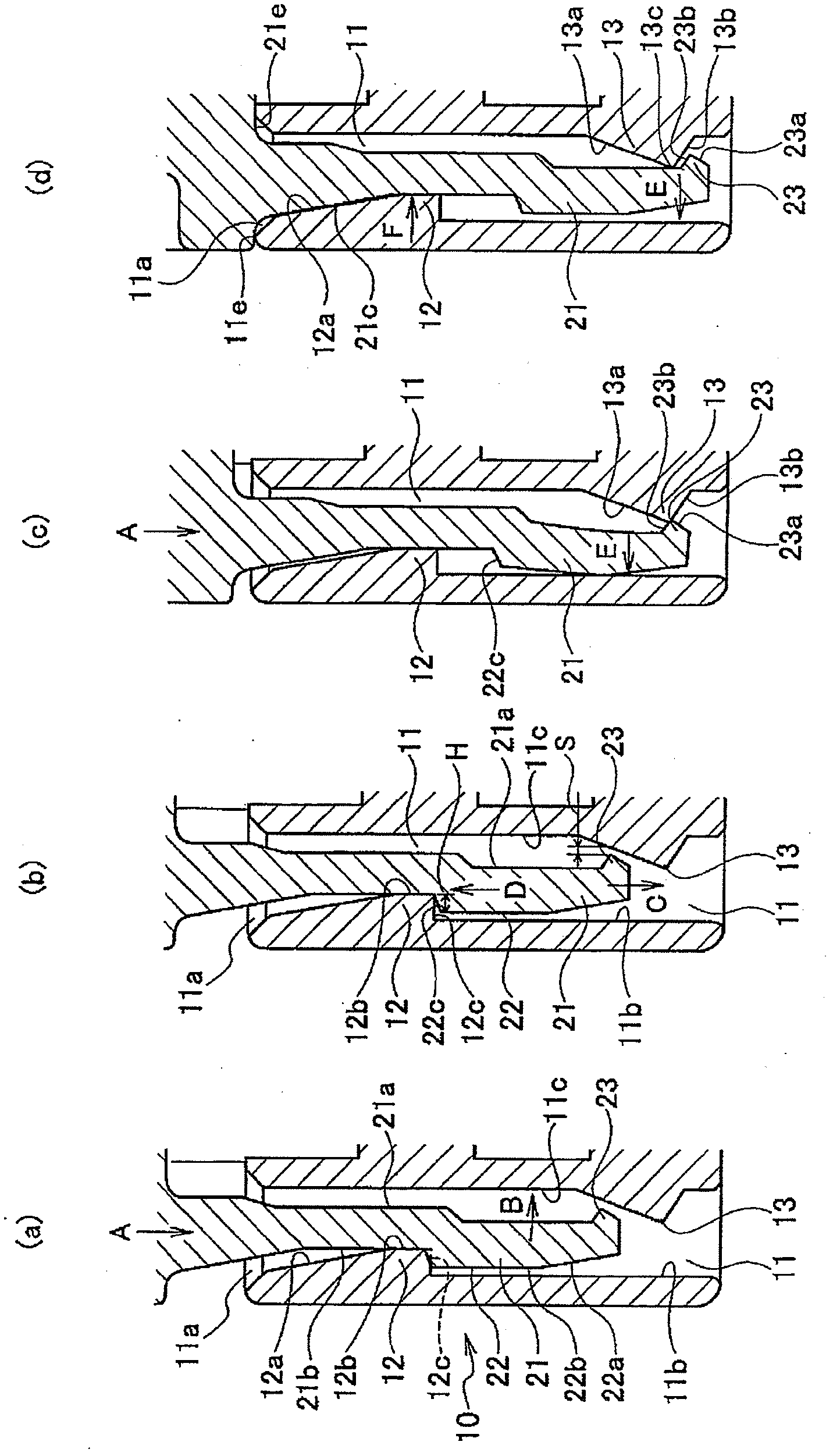

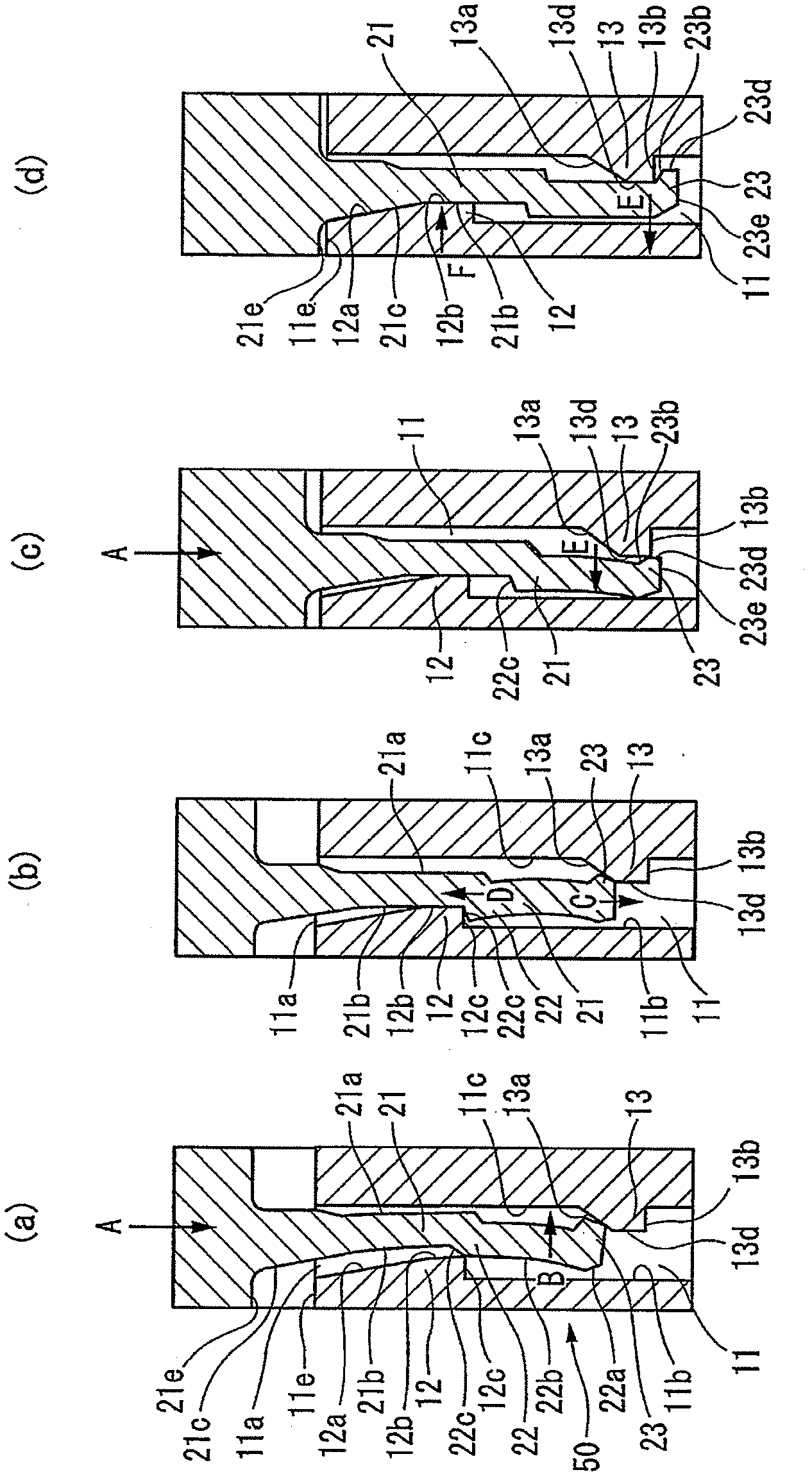

[0052] In the following, reference will be made to figure 1 and figure 2 A first embodiment of the present invention is described.

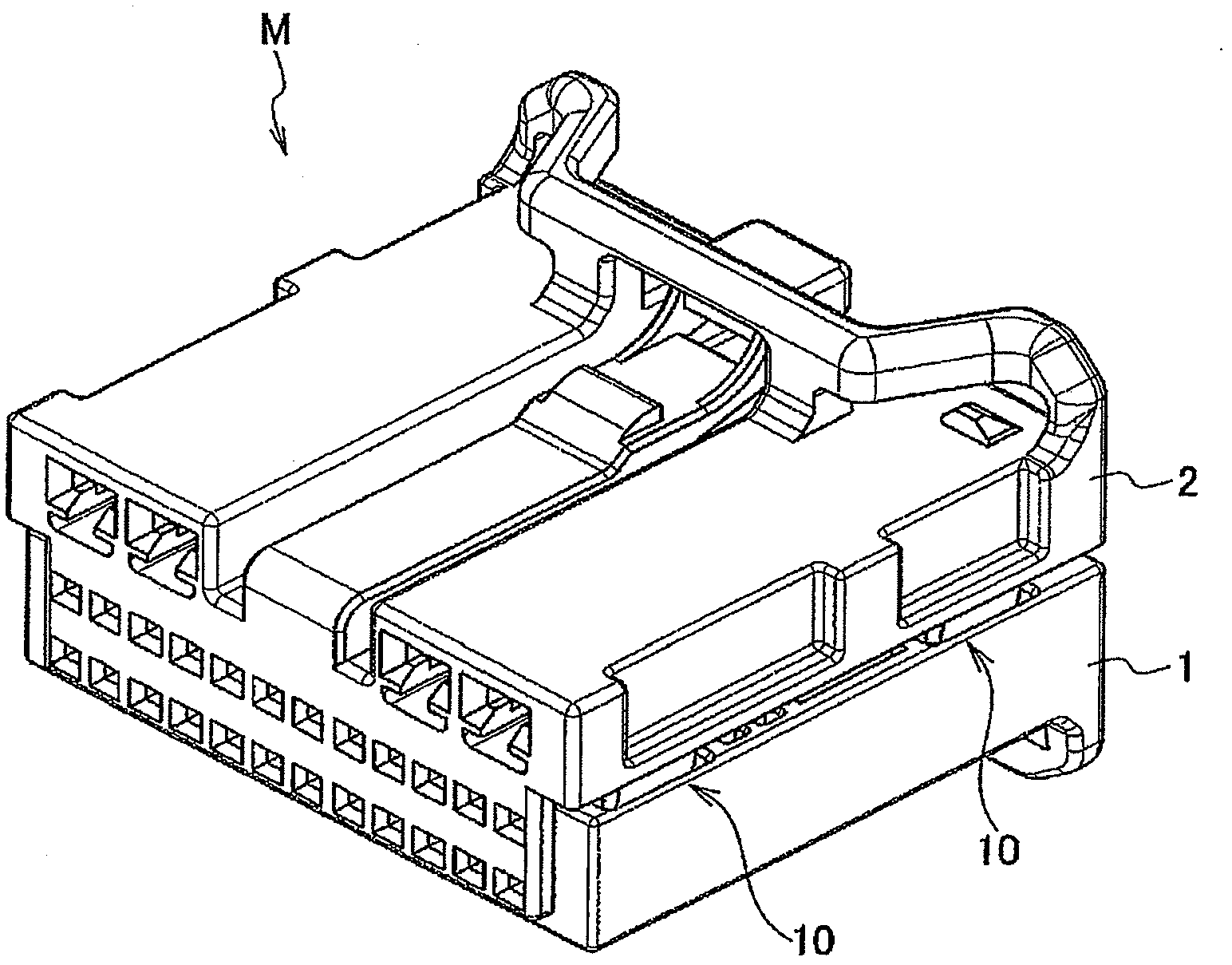

[0053] figure 1 Shows a cross-sectional view of the locking mechanism of the first embodiment of the present invention, showing the sequence of processes collectively elucidating the locking process. figure 1 (a) to figure 1 Multiple states of (d), where (a) shows a state occurring just before a temporary lock, (b) shows a temporary lock state, (c) shows a state occurring just before a permanent lock, and (d) shows the permanently locked state. figure 2 is an external perspective view of a connector employing this locking mechanism.

[0054] like figure 2 As shown, the locking mechanism 10 of the present embodiment is used as a locking means when two housings (resin moldings) 1, 2 are vertically connected together so as to assemble a connector M.

[0055] like figure 1 As shown, the locking mechanism 10 comprises a housing 1 (refe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap