Novel filtering device

A filtration equipment and a new type of technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of reducing the pressure of steam use, large waste, etc., and achieve the effect of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

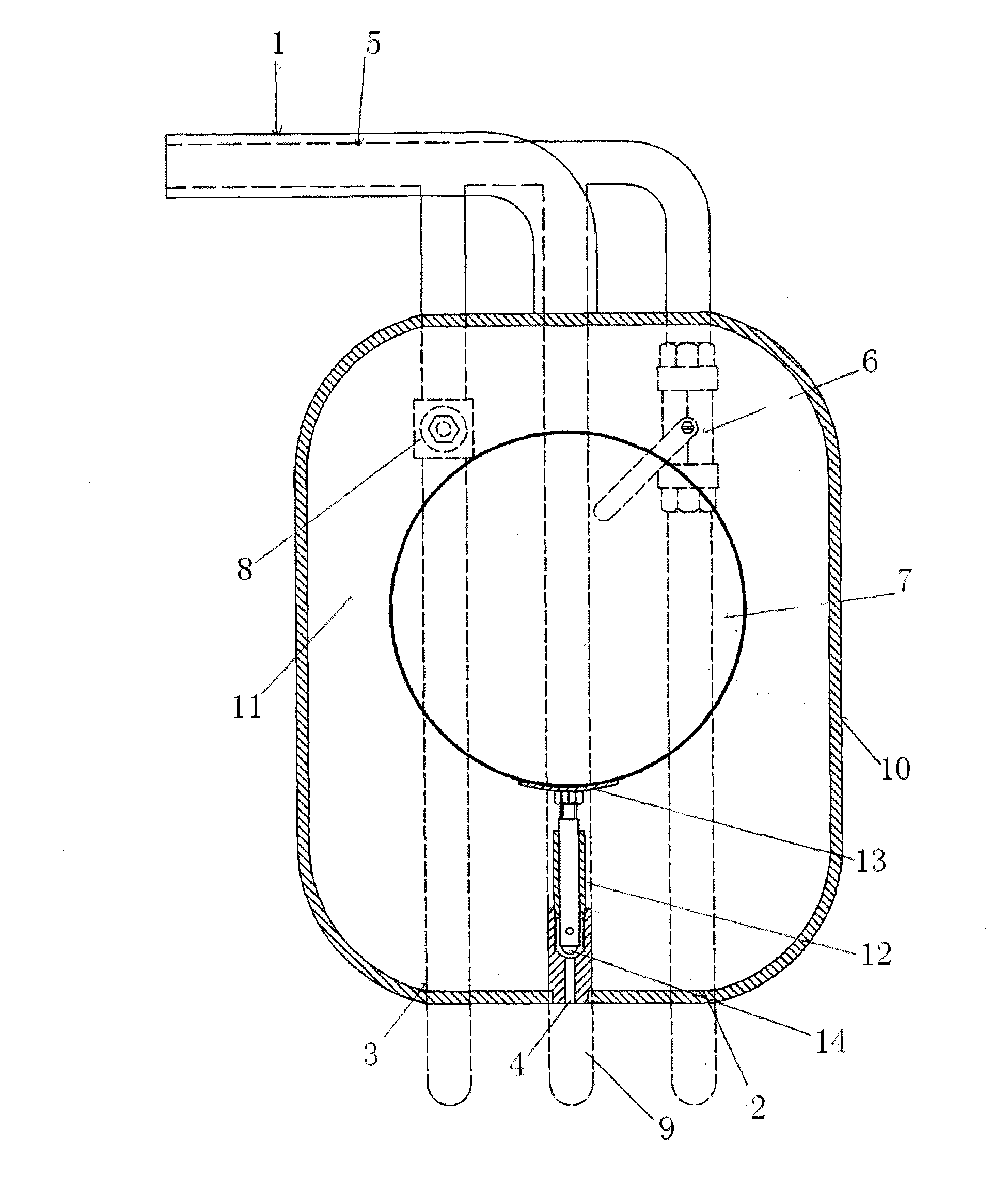

[0009] The present invention is referred to figure 1 , the new filter equipment, the housing 10 is equipped with an internal heat insulation box 11, the upper part of the internal heat insulation box 11 is inserted into the steam inlet pipe 1, and the bottom has a sewage outlet 2, an auxiliary drainage outlet 3 and an automatic drainage outlet 4, and the sewage pipe is connected The sewage outlet 2 and the water outlet 5 are provided with a manual switch 6, the auxiliary drainage outlet 3 is provided with a micro-opener 8, and the automatic switch 12 of the automatic water outlet 4 is installed in the internal heat insulation box, and the floating element 7 is installed on the automatic switch to automatically switch Connect the automatic water outlet 9.

[0010] see figure 1 During operation, the steam and condensed water enter the inner heat insulation box 11 from the steam inlet 1 together with the pressure during operation, and the space suddenly increases so that the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com