Adjustable boring cutter head and method for changing feed rate of cutter head

A boring tool and adjustable technology, applied in the direction of tool holder, etc., can solve the problems of unsatisfactory efficiency, difficult to guarantee machining accuracy, change of feed amount, etc., and achieve stable operation, compact device and multi-station installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

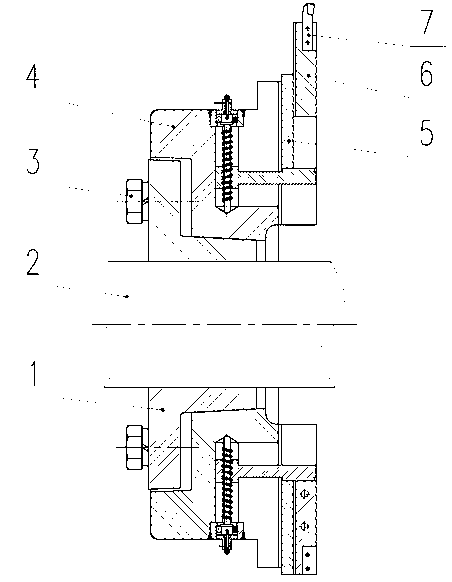

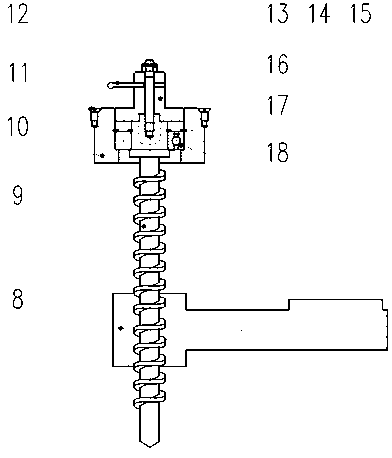

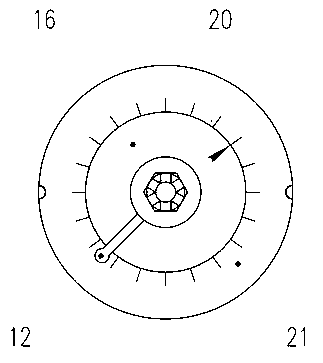

[0030] The accompanying drawings disclose the specific structures of the embodiments of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

[0031] Depend on figure 1 It can be seen that the present invention is composed of three parts: a shrink disc device, a tool feed adjustment device and a clamping accessory. The shrink disc device includes a shrink ring 1, an adjusting bolt 3 and a tapered hole cutter head 4. The shrink ring 1 is composed of a ring It is composed of a seat and a conical shrinking flap containing a shrinking groove. The center of the tapered hole cutter head 4 is a tapered hole. In the hole, the adjustment bolt 3 on the shrink ring seat is tightly connected with the tapered hole cutter head 4; the tapered hole cutter head is provided with an installation notch for the tool feed adjustment device. During specific implementation, in the installation notch There s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com