Vertical pneumatic two-way clamping device

A two-way clamping, upright technology, used in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large clamping area and clamping space limitation, and achieve small plane space and good force condition. , The effect of convenient manual loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

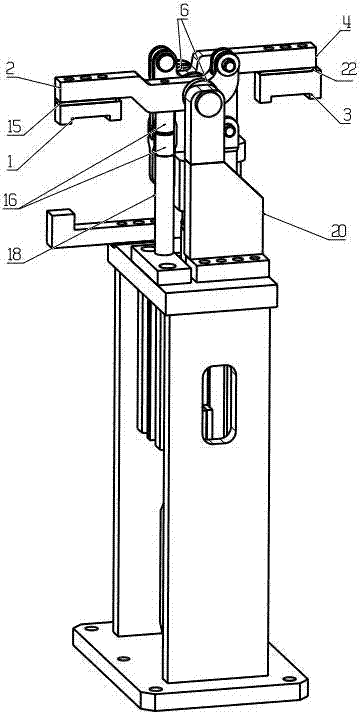

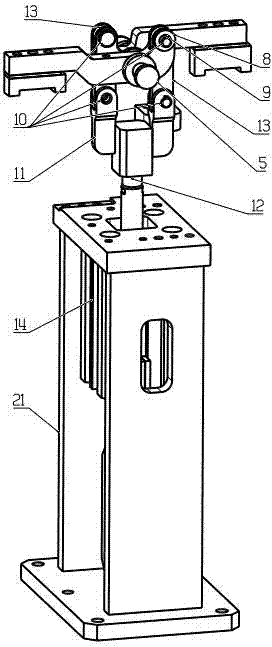

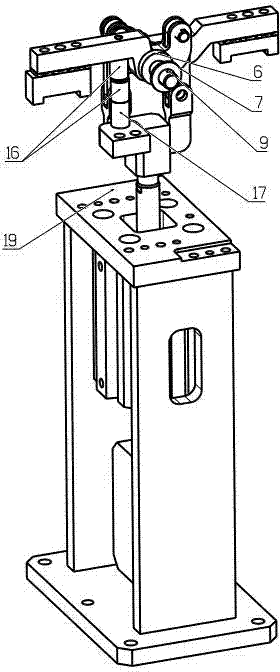

[0010] The large welding support 21 is fixed on the worktable, the cylinder 14 and the support 19 are fixedly connected with the large welding support 21 respectively, the support seat 20 and the large limit seat 18 are fixedly connected with the support 19 respectively, and the small limit seat 17 is fixed on the support base 20;" "The font connecting block 11 is fixedly connected with the cylinder 14 through the nut 12; the two connecting plates 13 are flexibly connected to the connecting block 11 through four groups of small hinge shafts 10, small washers 8, and small cotter pins 9 at one end, and the other ends are respectively Connected to the left rocker arm 2 and the right rocker arm 4; the left rocker arm 2 and the right rocker arm 4 are flexibly connected to the support seat 20 through the large hinge shaft 5, the large washer 7, and the large cotter pin 9, the left rocker arm 2, the right rocker arm An oil-free thrust washer 6 is installed between the rocker arm 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com