Working table

A workbench and tabletop technology, applied to workbenches, manufacturing tools, etc., can solve the problems of using manual operations, and achieve the effects of saving space, improving work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific implementation methods.

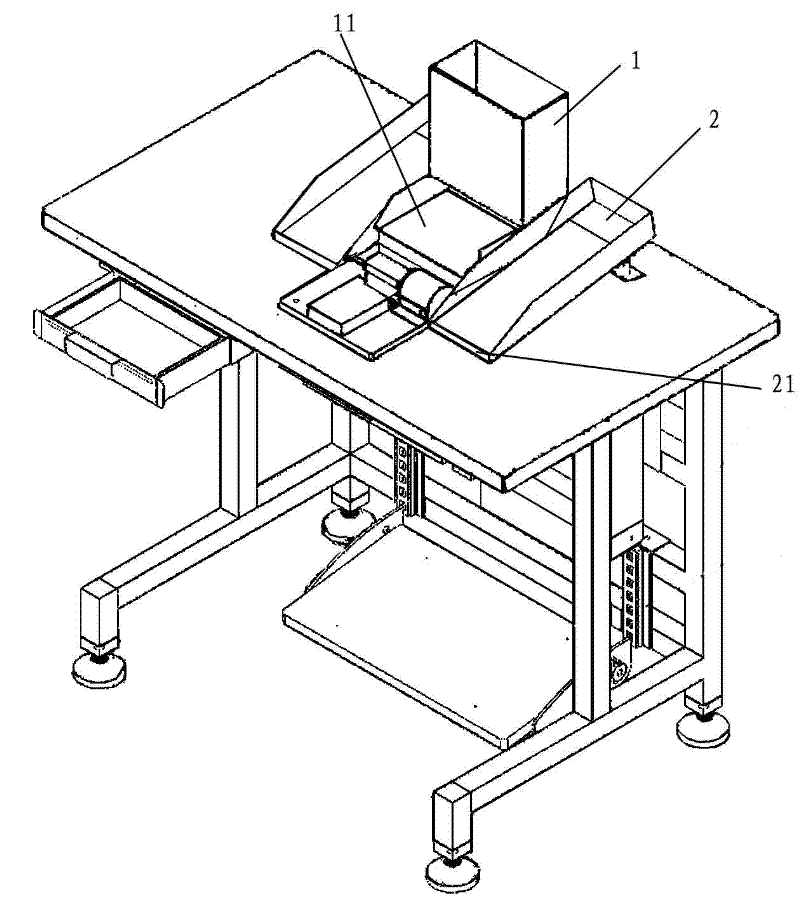

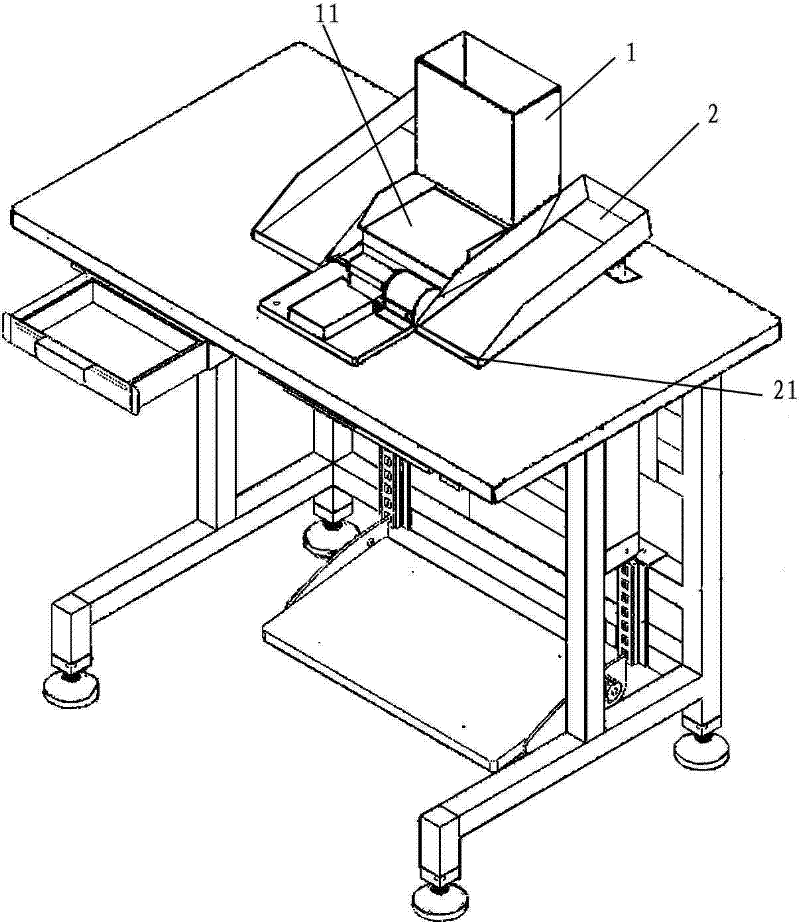

[0014] As shown in the figure, a workbench includes a table top and an operation area arranged on the table top, and is characterized in that the operation area is provided with a workpiece groove arranged in a "concave" shape around the operation jig, and the workpiece groove includes Operate the side slots 2 and middle slot 1 on the left and right sides of the jig.

[0015] The side tank 2 is in the shape of a bucket, and the bottom plate of the side tank is inclined towards the direction of the operator's position, and baffles 21 are arranged around the bottom plate of the side tank.

[0016] The middle tank 1 includes a rectangular box with an open upper end. A bottom plate 11 is extended from the bottom surface of the rectangular box toward...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap