Low-floor gate-type wheel-side motor rear axle for electric bus

A technology for electric passenger cars and wheel-side motors, which is applied in motion deposition, power units, vehicle components, etc., can solve the problems of electric vehicle cruising range limitation, high vehicle curb weight, poor handling stability, etc. , The structure design is compact and reasonable, and the effect of increasing the built-in space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

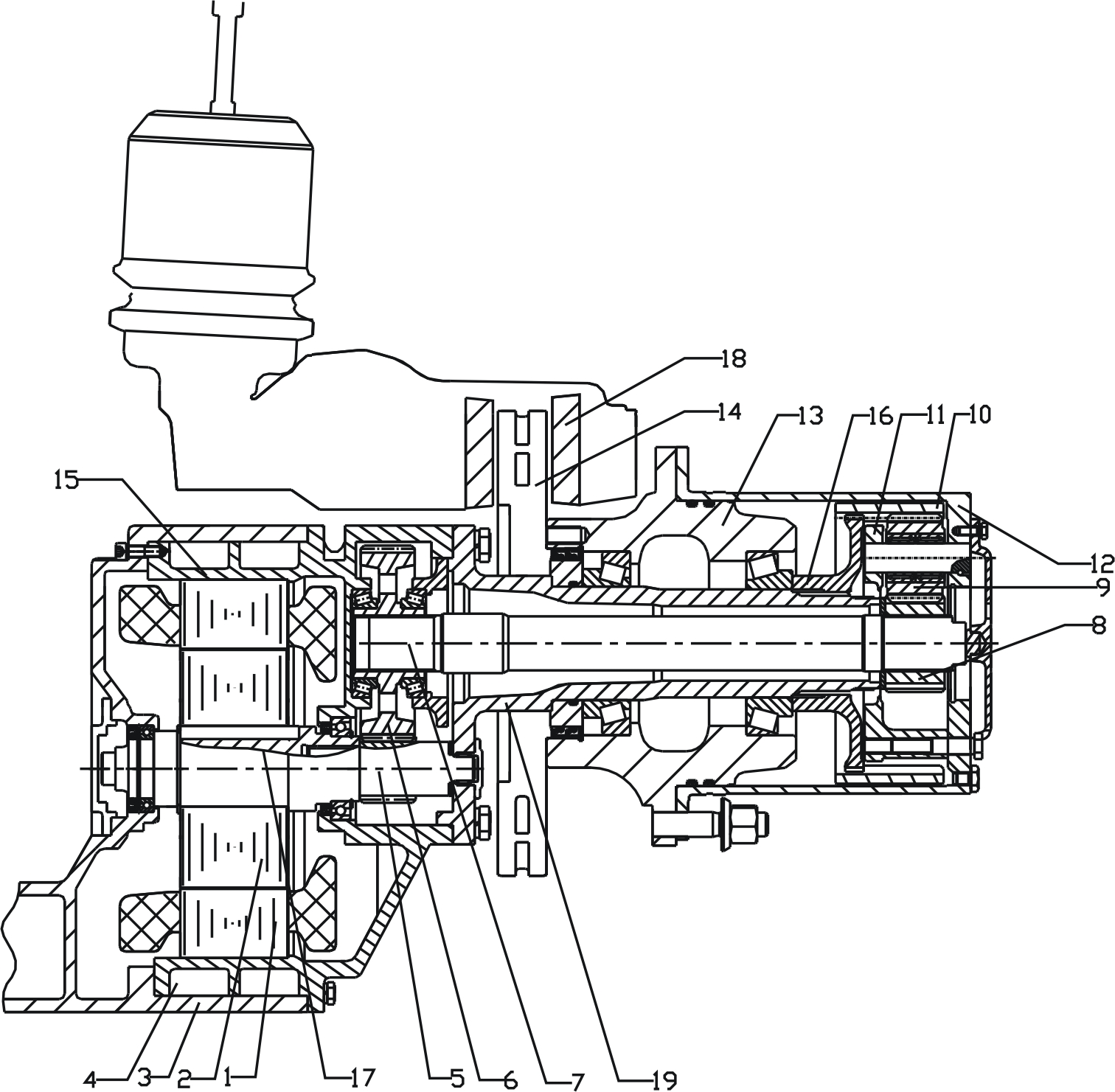

[0026] Low-floor gantry wheel motor rear axle for electric passenger cars, see figure 1 Shown: including axle housing, motor, primary reducer, secondary reducer, brake and hub;

[0027] The front end of the housing 15 of the first-stage reducer is nested in the axle housing 3 to form an annular combined water jacket 4. The water inlet and outlet of the combined water jacket are arranged on the wall of the axle housing and connected with the external water tank. connected to achieve motor circulation cooling, the middle part of the outer wall of the front end of the primary reducer housing is provided with an annular non-enclosed heat dissipation rib, and the annular non-enclosed heat dissipation rib is symmetrically arranged with two gaps, which are respectively connected to the axle housing. The water inlet is opposite to the water outlet, and the gap opposite to the water inlet is axially provided with arc-shaped triangular shunt ribs. The motor stator 1 is fixed in the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com