Material mixer for chemical production

A technology for chemical production and mixers, used in mixer accessories, mixers with rotary mixing devices, chemical/physical processes, etc., can solve problems such as uneven materials, poor production quality, and inability to effectively screen, reduce Residue, reduce screen clogging, increase the effect of stirring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

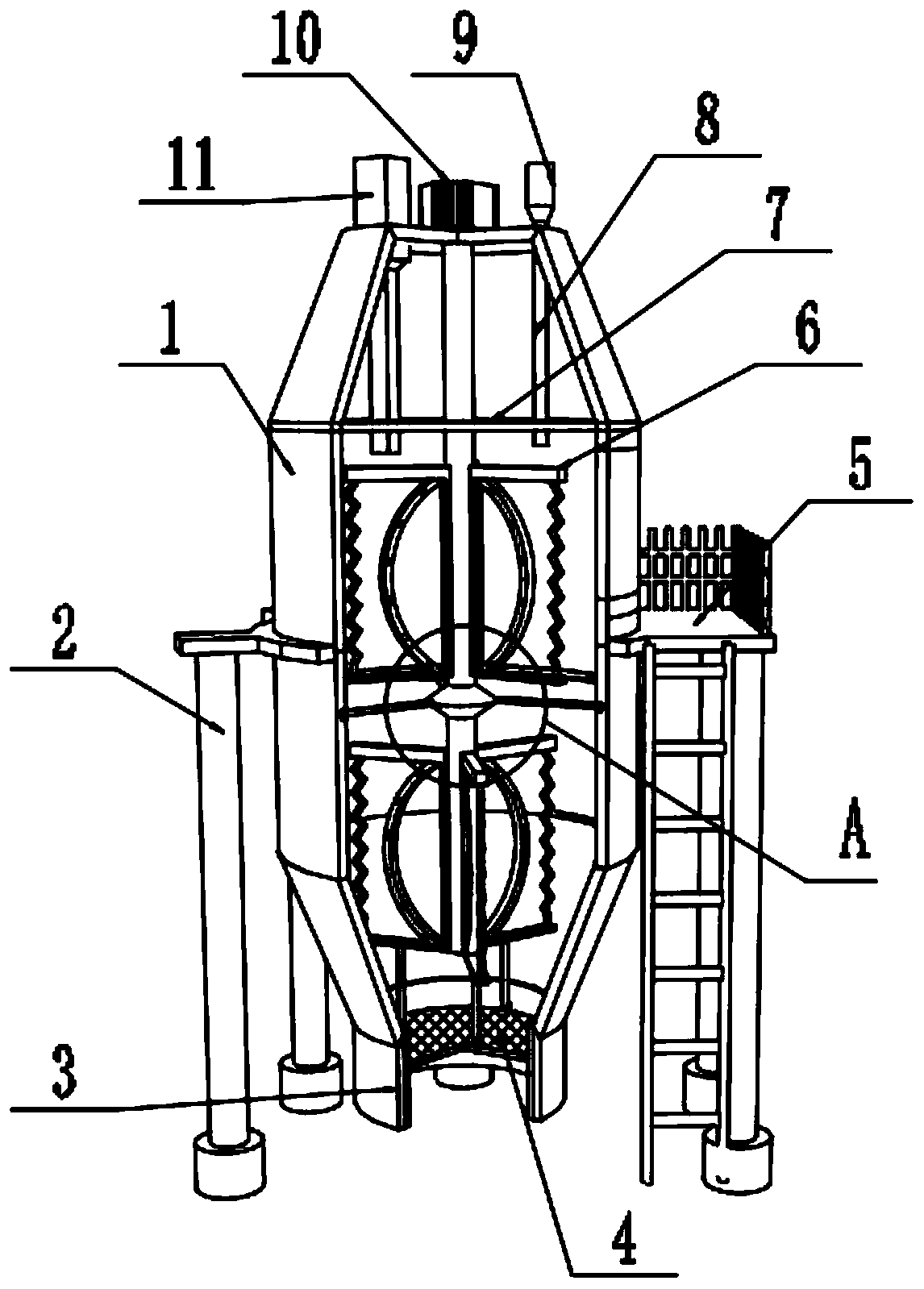

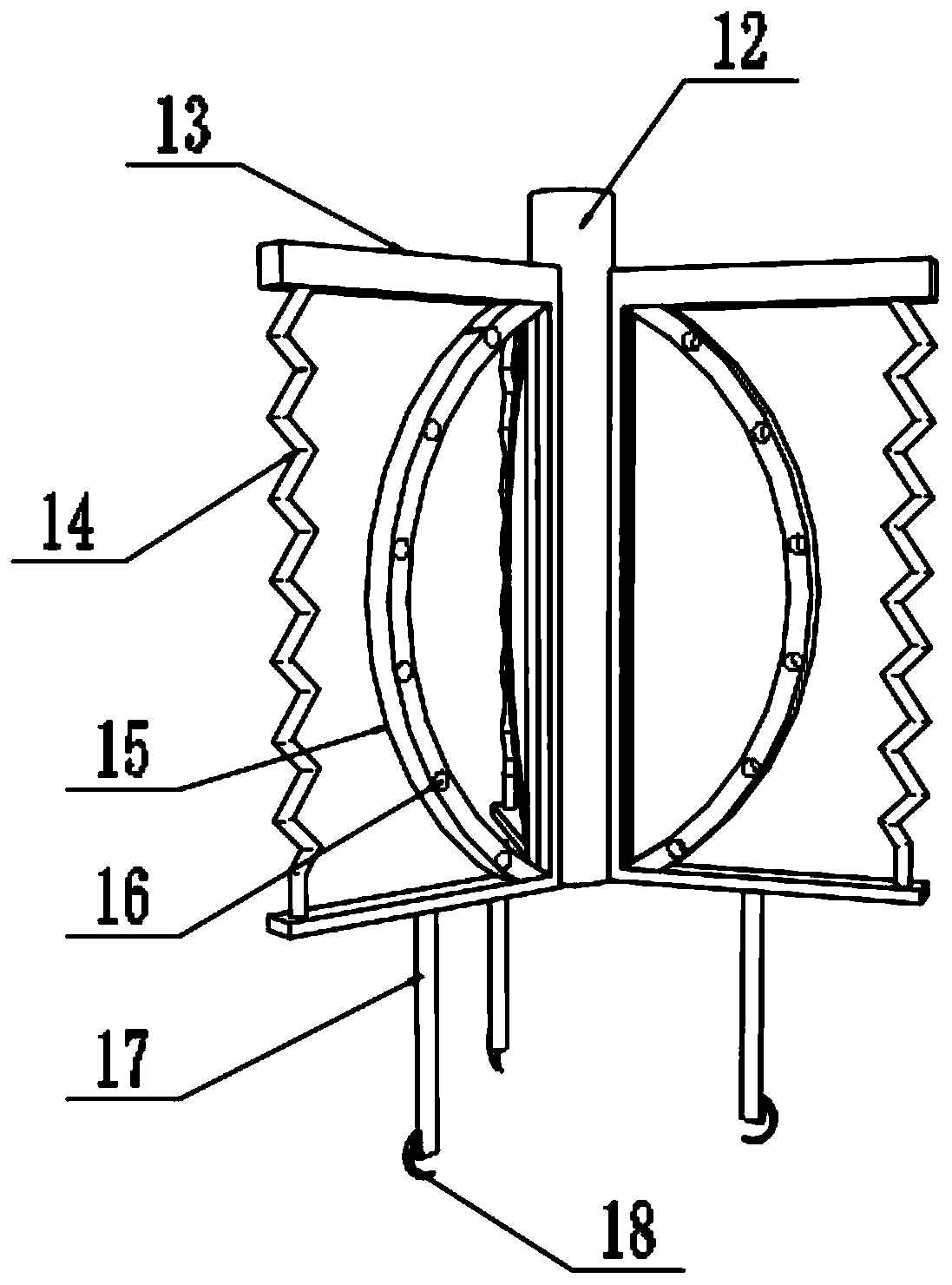

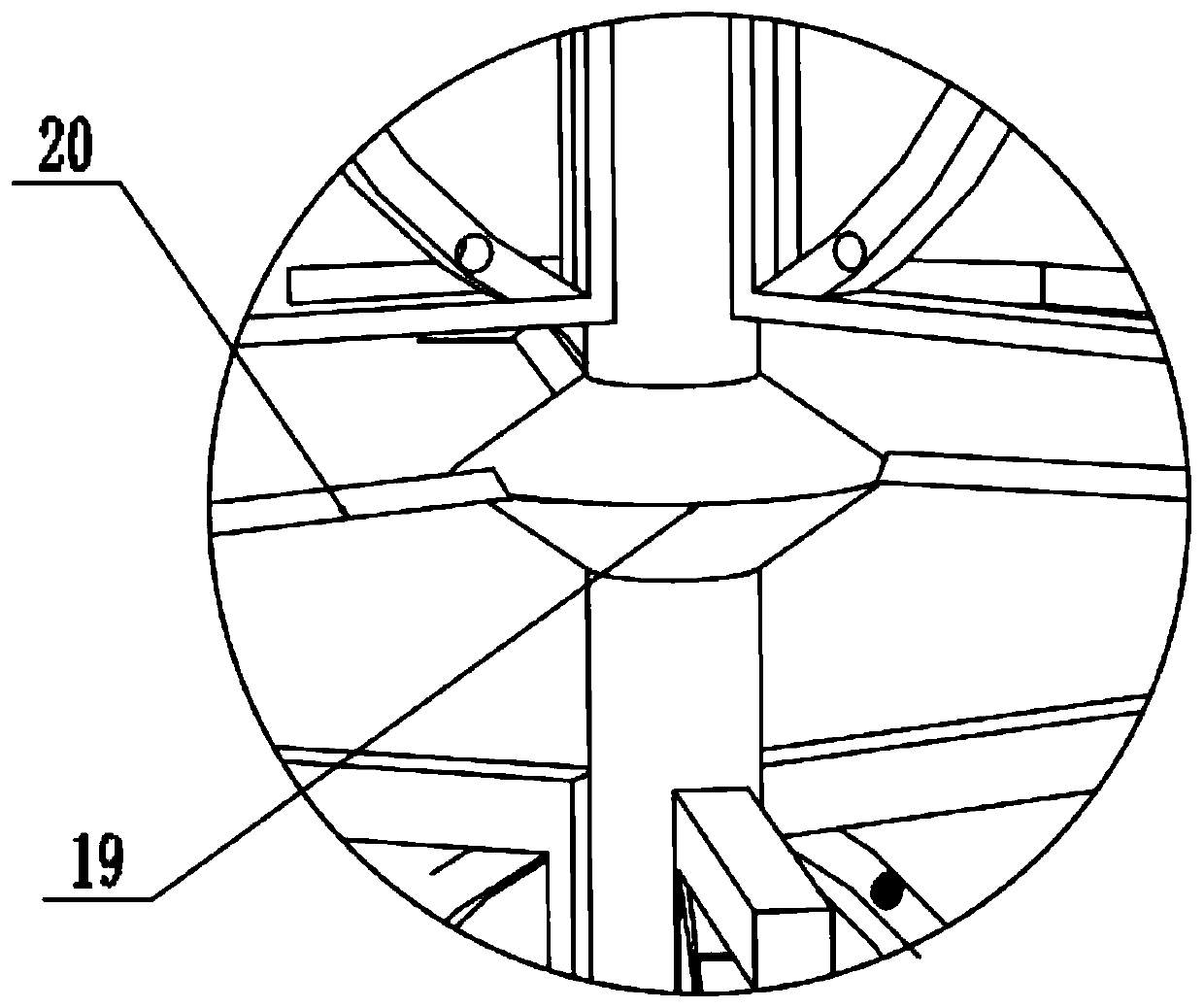

[0030] A material mixer for chemical production, such as Figure 1-4 Shown, comprise tank body 1, the first feed hopper 9, the second feed hopper 11, lower hopper 3 and motor 10, the side wall of tank body 1 is welded with observation platform 5 and more than three pillars 2, can pass through Observation platform 5 carries out routine inspection and maintenance to tank body 1; described first feed hopper 9 and second feed hopper 11 are welded on both sides of tank body 1 top respectively, the bottom end of first feed hopper 9 and the second feed hopper The bottom end of the feed hopper 11 is respectively welded with the first feed pipe 8 and the second feed pipe, which can be fed in different proportions through the first feed hopper 9 and the second feed hopper 11, improving the production quality of chemical products The motor 10 is fixed on the top of the tank body 1 through the motor base, and the output shaft of the motor 10 is connected with the stirring frame 6; the low...

Embodiment 2

[0038] A material mixer for chemical production, such as figure 1 and Figure 5 As shown, in order to solve the problem that the tank body is difficult to clean; this embodiment makes the following improvements on the basis of Embodiment 1: the inner top of the tank body 1 is welded with an inner top platform 7, and the bottom end of the inner top platform 7 is welded with a Spray frame 26, the bottom end of spray frame 26 is welded with several nozzles 27, and the top of spray frame 26 is welded with water pipe 25, and water pipe 25 can connect water source, and after using equipment, connect water pipe 25 to water source and pass through nozzle 27 Spraying the inside of the tank body 1; reducing the difficulty of cleaning the tank body 1 and the labor intensity.

[0039] When this embodiment is in use, after the chemical products are stirred, the water pipe 25 is connected to a high-pressure water source, and the water source enters the spray rack 26 through the water pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com