Engine dismounting conveyer system for scraped car dismounting line

A technology for conveying systems and scrapped cars, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of low efficiency of conveying and dismantling, low degree of automation, etc., to improve dismantling reliability and high work efficiency , the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

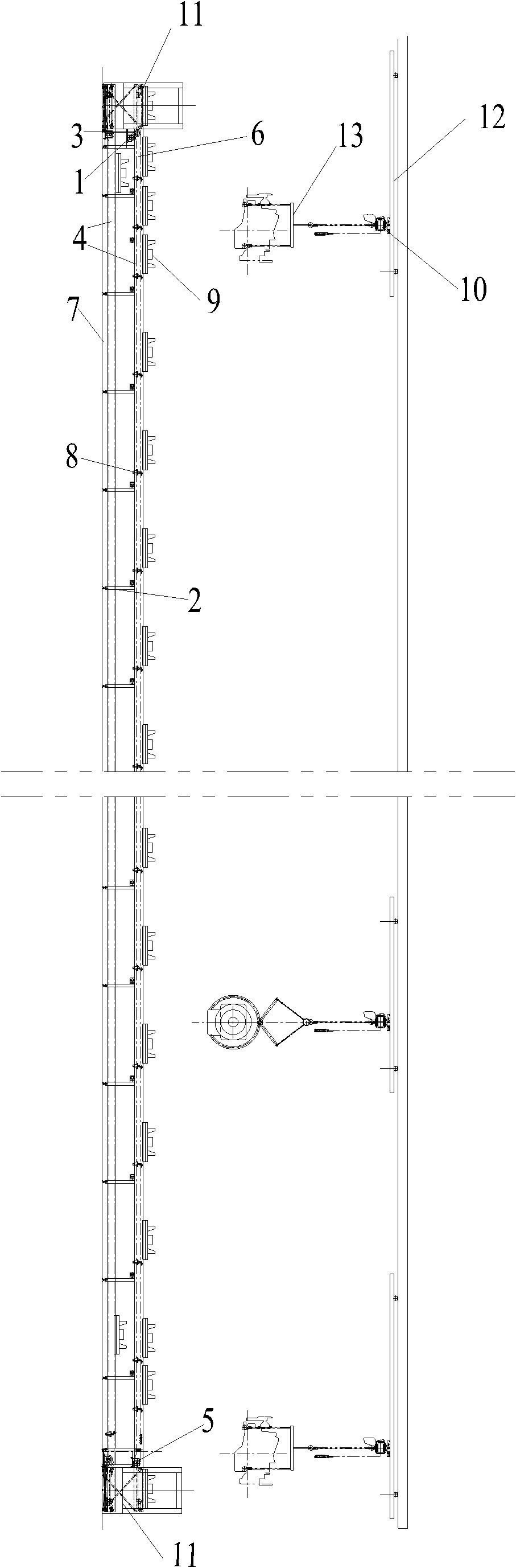

[0014] Such as figure 1 As shown, the present invention is an engine dismantling conveying system of a scrapped car dismantling line, which is used to completely disassemble the engine disassembled from a scrapped car. The engine dismantling conveying system includes a supporting rail frame 2, a conveying plate chain installed on the supporting rail frame 2, a 360° rotating process tray 9 for supporting the engine on the conveying plate chain, and a driving mechanism connected with the conveying plate chain , the grasping component and the PLC module of the grasping engine located above the conveying plate chain, the driving mechanism and the grasping component are connected with the PLC module, and the grasping component includes a circulating slide rail 12, an electric hoist 10 sliding on the circulating slide rail 12 and The hanger 13 connected on the electric hoist 10 is provided with a dismantling station of the engine on the conveying plate chain according to the conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com