Variable-inclination carrier roller set

A technology of roller sets and idlers, which is applied in the directions of rollers, conveyor objects, transportation and packaging, etc., can solve the problems of single function of idler sets, high installation and maintenance costs, poor interchangeability of idler sets, etc., and achieve Good performance, improved maintenance, and convenient design and manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

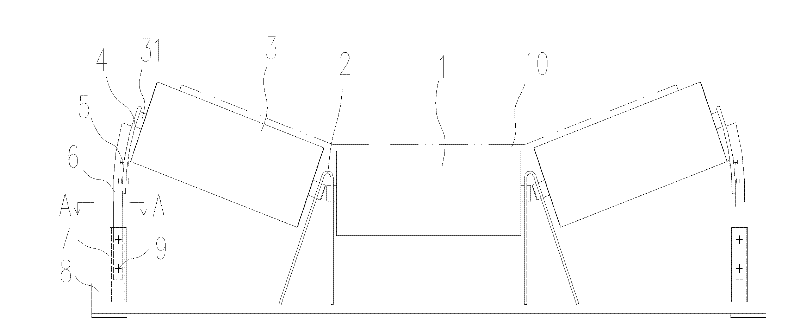

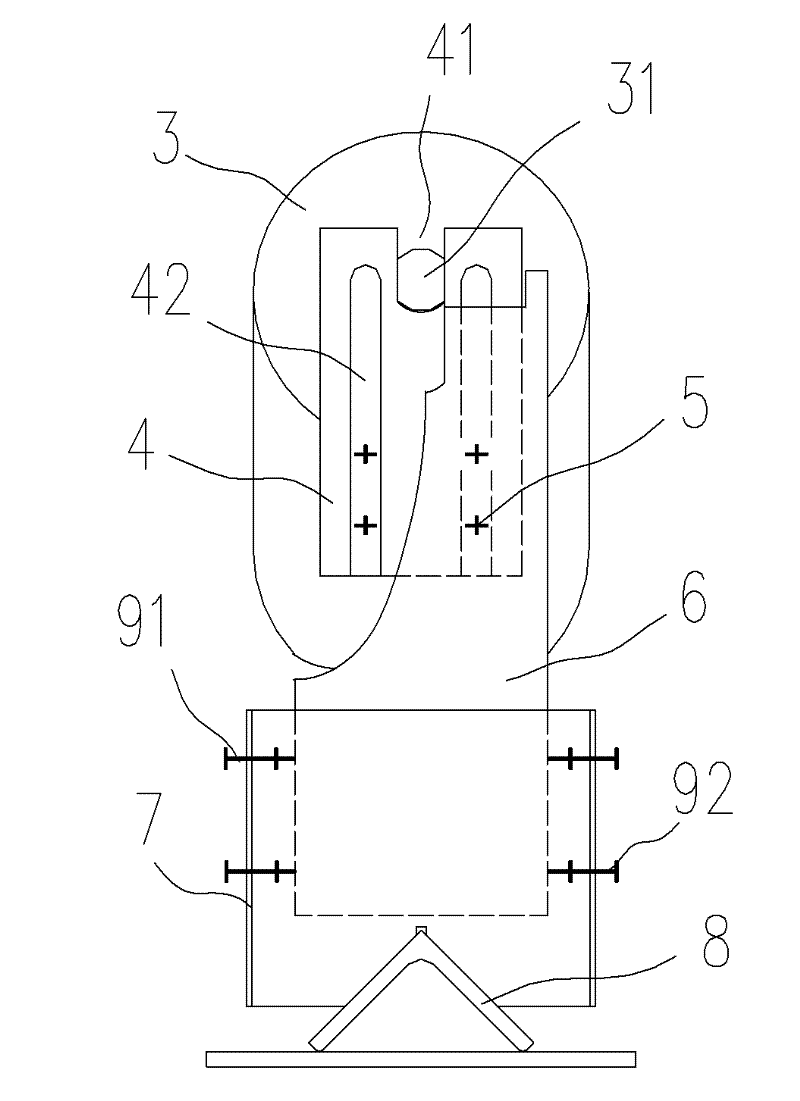

[0013] Such as figure 1 As shown, the present invention includes an intermediate idler 1 and side idlers 3 located at both ends of the intermediate idler 1 , and the inner shaft ends of the intermediate idler 1 and the side idlers 3 are supported on the intermediate support 2 .

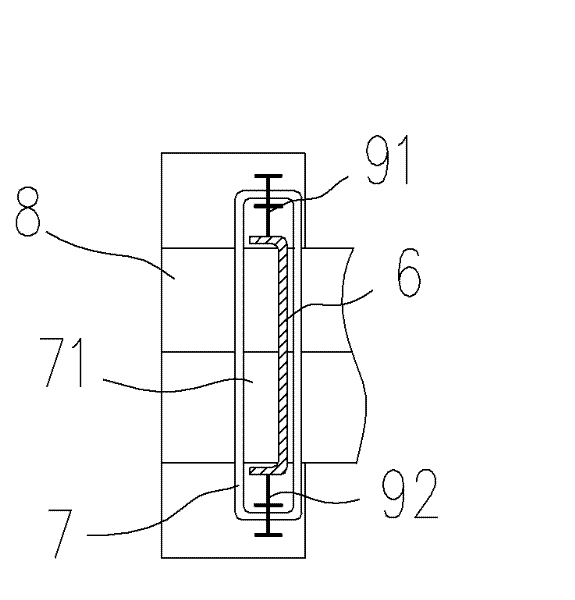

[0014] The top of the base 8 is fixed with a connecting sleeve 7 that is socketed with the side bracket 6. There is a slot 71 for inserting the lower end of the side bracket 6 in the middle of the connecting sleeve 7. The length of the slot 71 in the running direction of the adhesive tape 10 is greater than that of the side bracket 6. The length in this direction, the connecting sleeve 7 has several screw holes on both sides of the running direction of the adhesive tape 10, and bolts 91, 92 are fixed in the screw holes, and one end of the bolts 91, 92 can extend horizontally into the slot 71 to connect the side brackets. 6 Clamp on both sides.

[0015] The side bracket 6 is provided with a vertical a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com