Push-flow circulating microbubble and surface aeration membrane biological reactor

A membrane bioreactor and surface aeration technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low oxygen utilization rate and high energy consumption, and achieve The effect of reduced operating cost, large circulation volume and low circulation energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

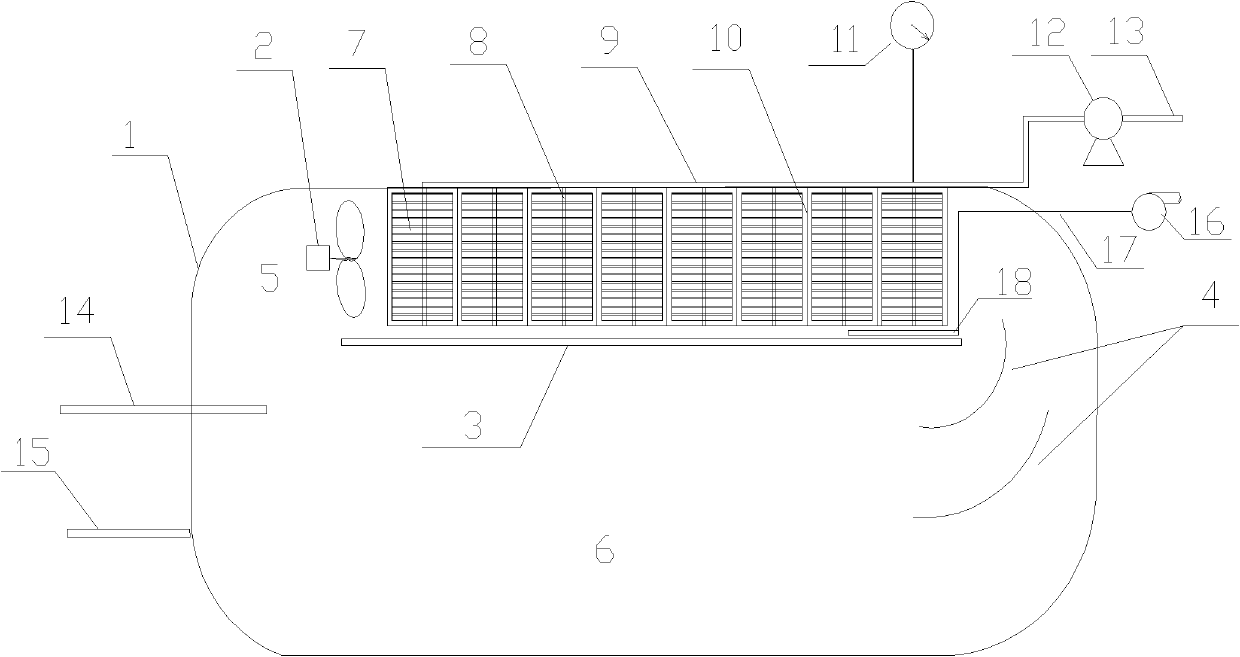

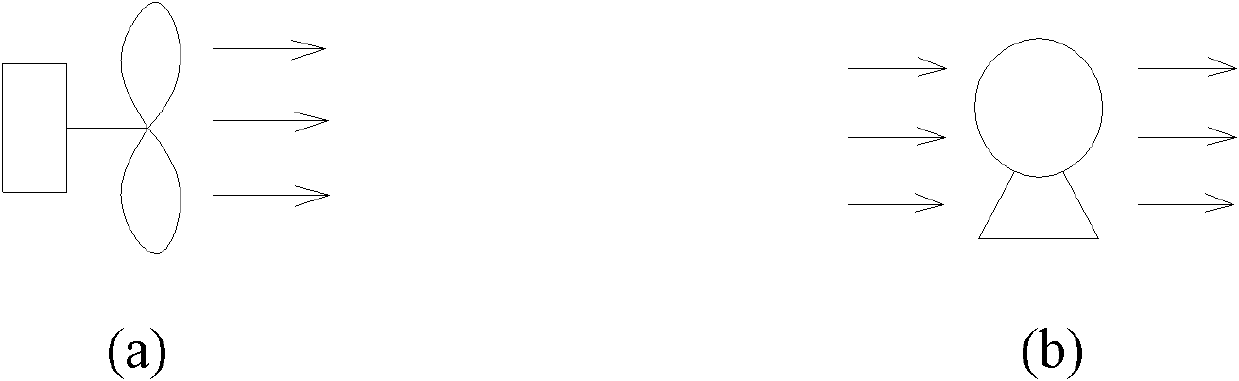

[0040] The plug-flow circulating microbubble and surface aeration membrane bioreactor process of the present invention improves the aeration efficiency in the activated sludge method membrane bioreactor, and adopts the method of combining surface aeration and oxygenation with microbubble aeration, Oxygen utilization can be increased from 3% to 20%. Thereby doubling the size of the fan. If the scale of the fan is reduced, the flow rate of the gas-water mixed flow in the membrane bioreactor will not meet the requirements of membrane flushing. At this time, it is necessary to use a high-efficiency pusher to drive the water flow to flush the membrane module and realize the circulation of the mixed flow of activated sludge in the reactor and the suspension of activated sludge.

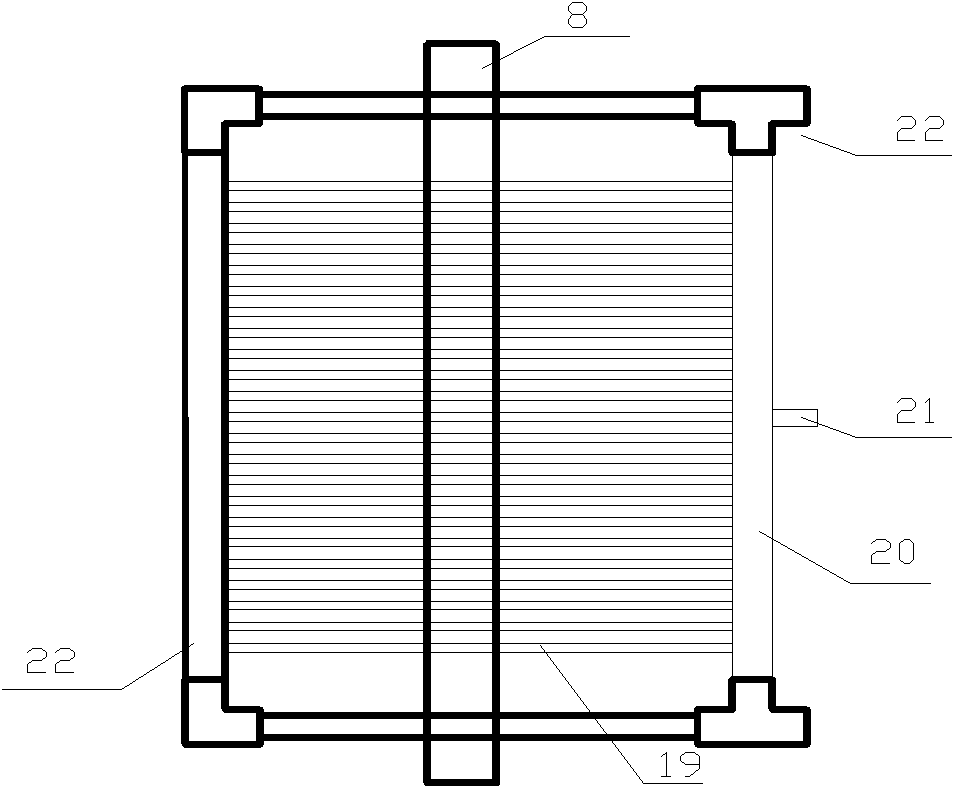

[0041] In order to be able to wash the membrane filaments in all directions, the installation direction of the membrane filaments is also changed to be horizontal, which is consistent with the direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com