Mold for preparing glass beverage bottle and method for preparing glass beverage bottle

A beverage bottle and glass technology, which is applied in the field of molds for preparing glass beverage bottles and the field of preparing glass beverage bottles, can solve the problems of long production cycle, high production efficiency, and difficult processing, etc., and achieve easy processing and manufacturing, high-efficiency dimensional accuracy , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

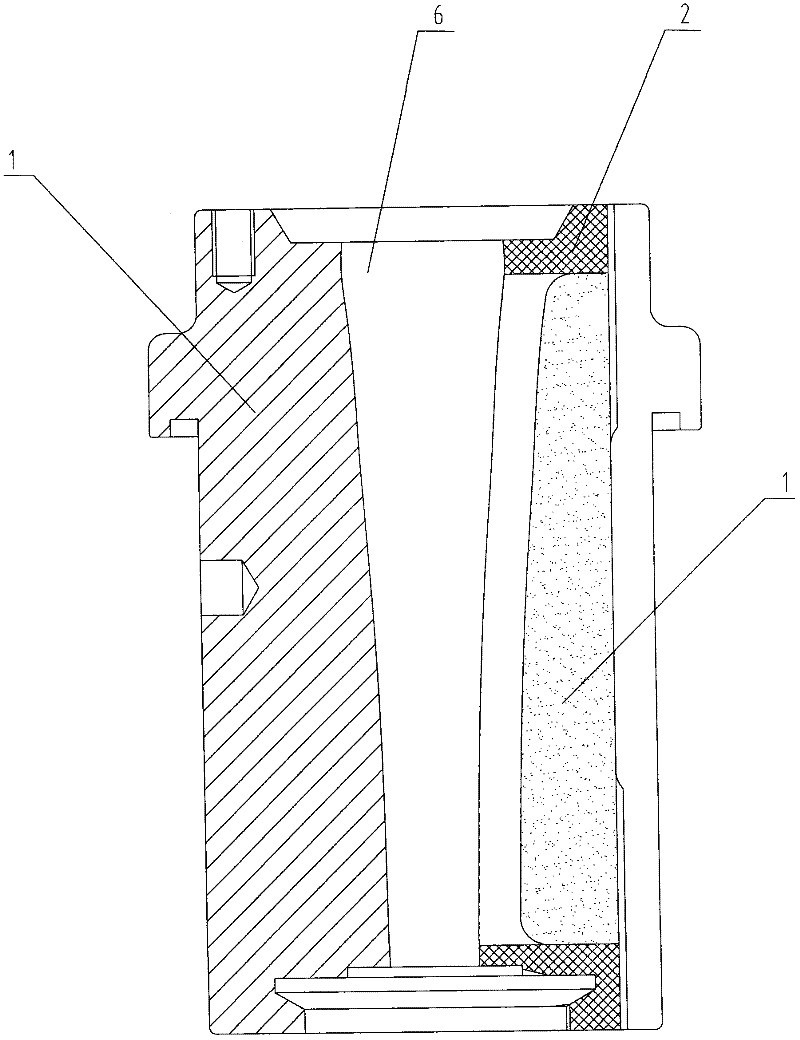

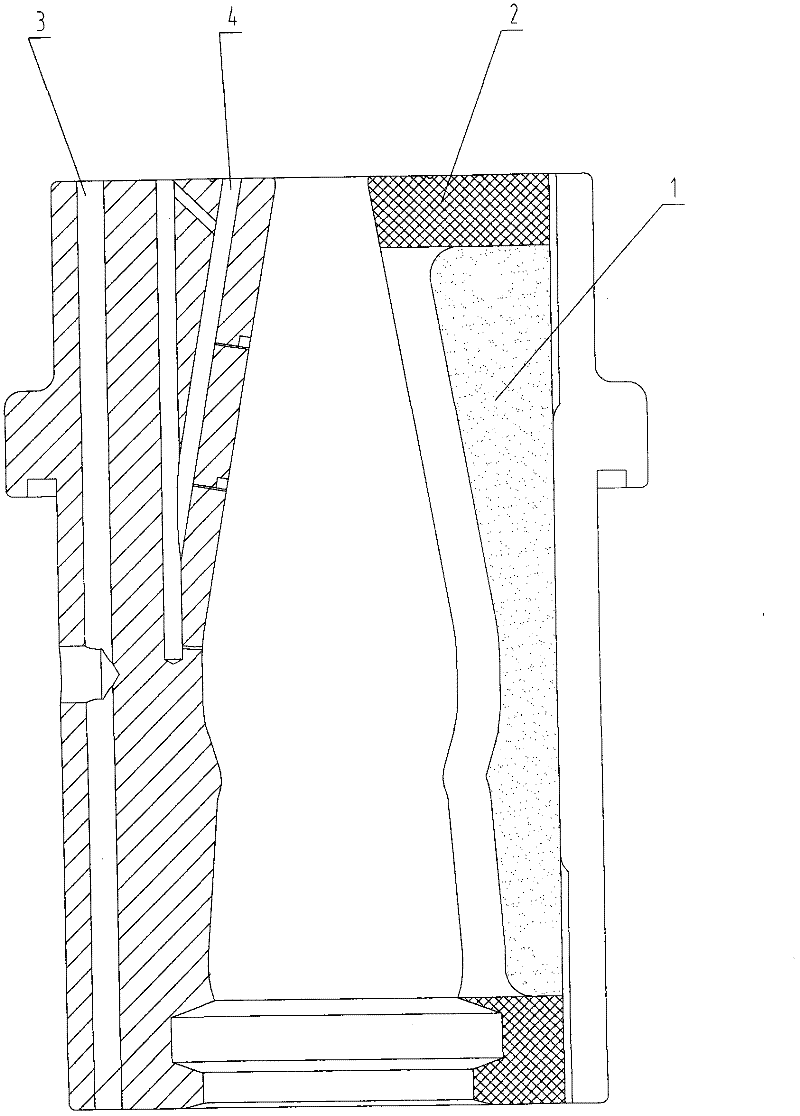

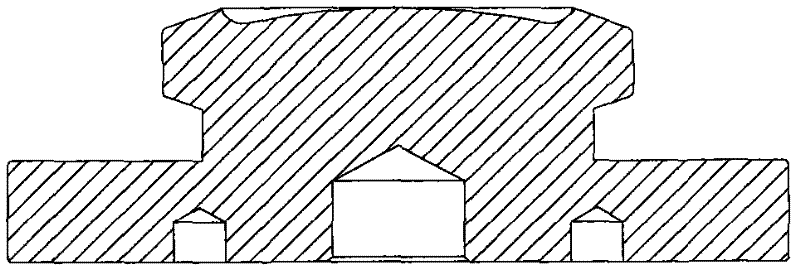

[0024] Example 1, see figure 1 figure 2 , image 3 and Figure 4 , the invention discloses a mold for preparing a glass beverage bottle, especially a glass beer bottle, comprising a blank mold, a forming mold and a mold bottom, the mold cavity of the blank mold is in the shape of a glass beverage bottle blank;

[0025] The forming mold is fixed on the bottom of the mold, and the cavity of the forming mold is the final shape of the glass beverage bottle body;

[0026] The molten glass drips into the upside-down primary mold through the material channel. The primary mold is composed of a convex-concave mold 1 and a bonding surface 2. After forming the blank 6 in the primary mold, it is turned over and sent to the forming mold. The forming mold It is composed of convex and concave molds 1 and bonding surface 2, and there are exhaust holes 13 and exhaust grooves 4 on the wall of the forming mold. The air between the blanks 6 is discharged, and the forming mold is fixed on the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap