Bamboo plywood beam structure

A bamboo plywood and beam structure technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of beam web buckling damage, beam bearing capacity reduction, and insufficient shear strength, etc., and achieve high processing accuracy and increase Integrity, the effect of improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

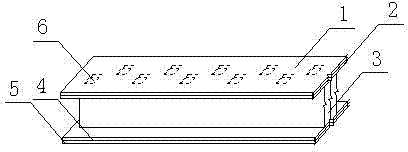

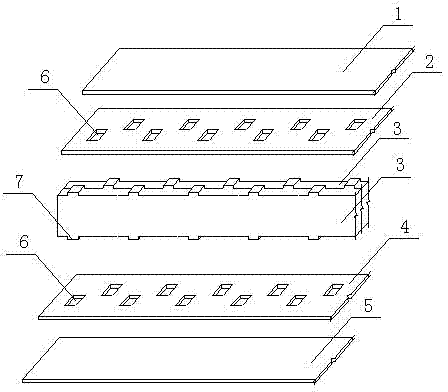

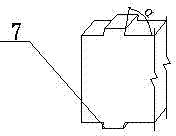

[0020] The bamboo plywood girder structure of the present invention comprises an upper flange plate, a lower flange plate and a web made of bamboo plywood. The upper flange inner plate 2 is connected, and the lower flange plate is formed by connecting the lower flange outer plate 5 and the lower flange inner plate 4 located on the upper side of the lower flange outer plate 5, and the web includes superimposed multiple web veneer 3, the number of web veneer 3 can be adjusted according to the size of the shear force borne by the beam, the upper and lower surfaces of the web veneer 3 are provided with tenons 7 arranged at intervals, two adjacent web veneers 3 The tenons 7 on the top are arranged in a staggered manner, the upper flange inner plate 2 and the lower flange inner plate 4 are provided with tenon grooves 6 matching the size and distribution position of the tenons 7, and the tenon 7 is embedded in the tenon grooves 6 , The tenon 7 is closely connected with the tenon groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com