Keel connecting device for suspension type curtain wall

A connecting device and suspension technology, which is applied in the field of building curtain wall system, can solve the problems of curtain wall panels falling, cumbersome keel installation process, and many types of accessories, so as to improve the uniformity of force, easy to improve and implement, and convenient and quick to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

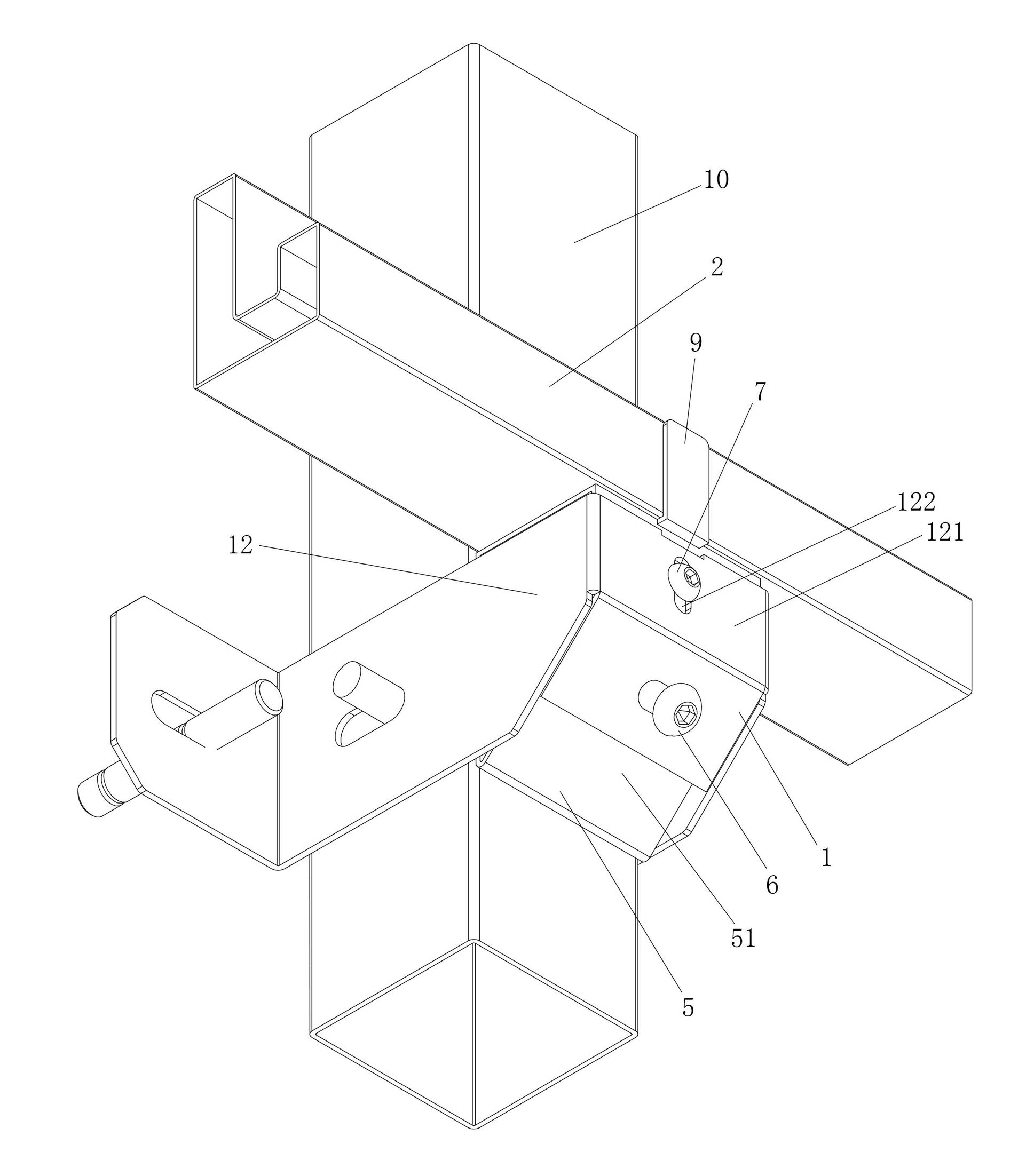

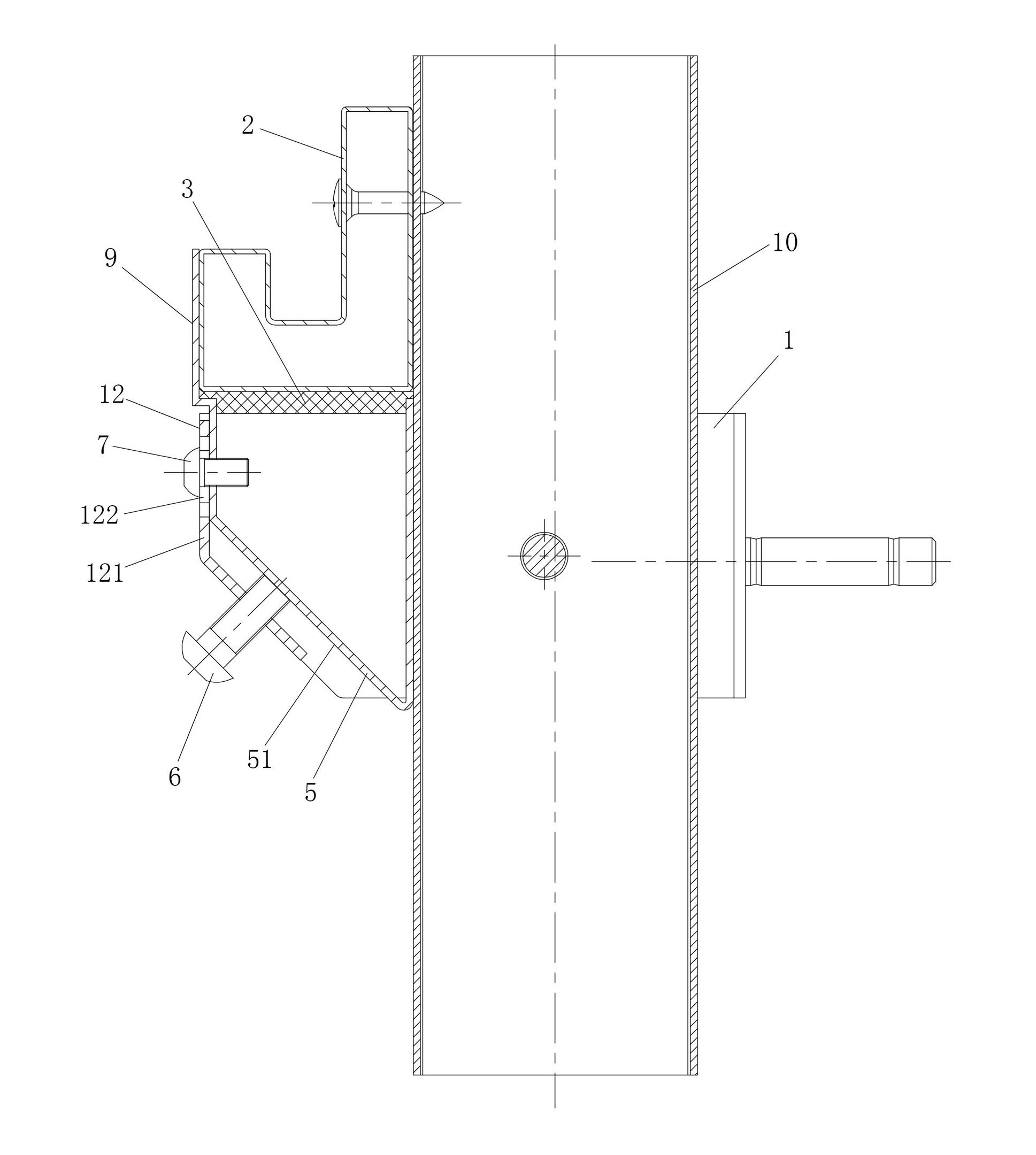

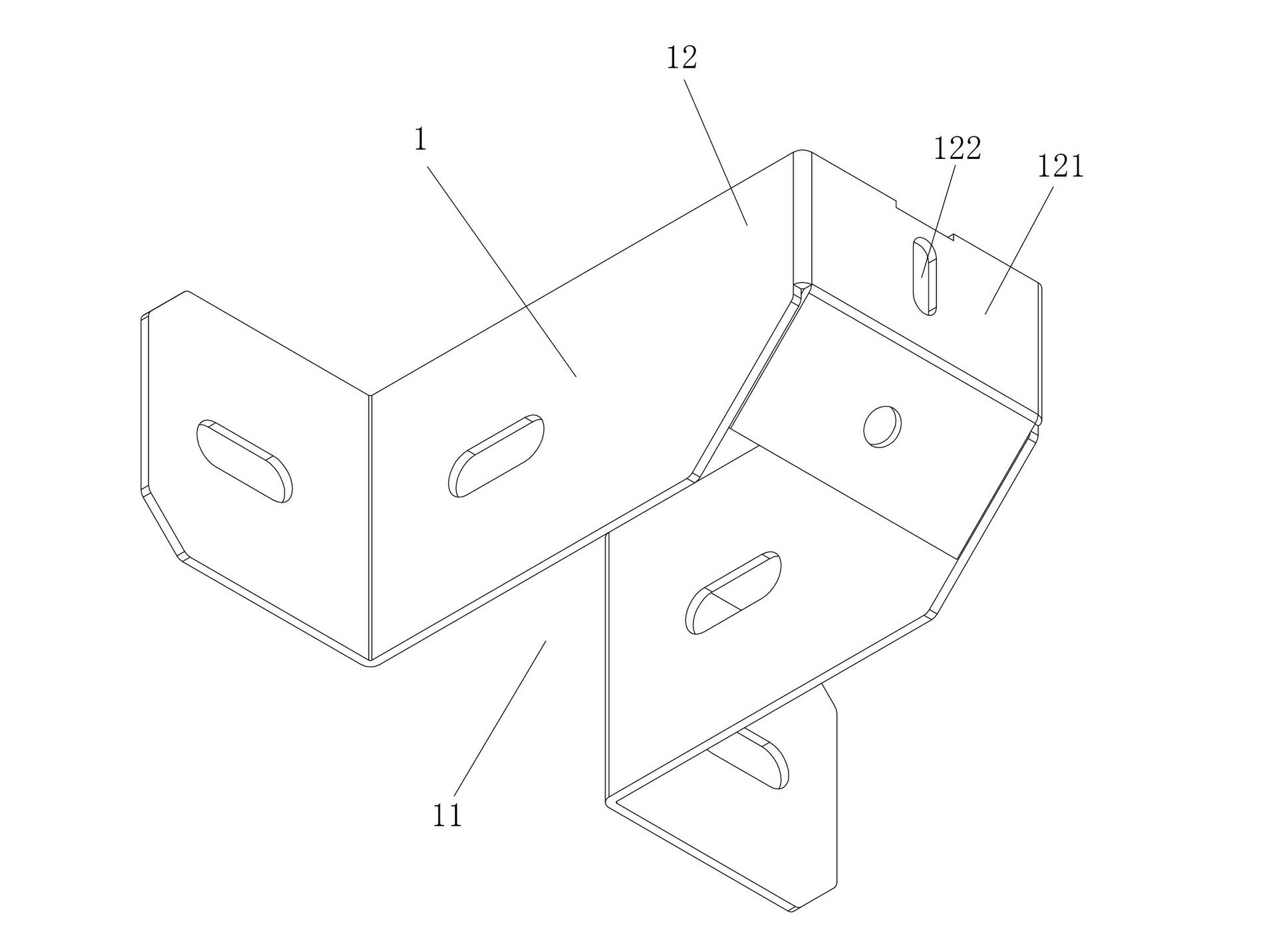

[0039] Figure 1 to Figure 5 Shows the first embodiment of the keel connection device for suspended curtain wall of the present invention, the connection device includes a connector body 1, the connector body 1 is provided with a vertical keel accommodation part 11 and a vertical keel accommodating part 11 The horizontal keel supporting part 12 at the front end is provided with a jacking assembly which can adjust the supporting height. Such as figure 1 with figure 2 As shown, after the connector body 1 fixes the vertical keel 10 and the horizontal keel 2 on the building wall (not shown in the figure), the vertical keel 10 of the curtain wall is placed in the vertical keel accommodating part 11, and is passed through the fastener Connected with the connector body 1, the rear end of the connector body 1 is provided with mounting ears that can be connected with the building wall through fasteners. Fasteners are connected to the vertical keel 10, and the jacking assembly is ar...

Embodiment 2

[0045] Figure 6 to Figure 8 It shows the second embodiment of the keel connection device for suspended curtain wall of the present invention. In this embodiment, the connection device includes a connector body 1, and the connector body 1 is provided with a vertical keel accommodation part 11 and a vertical keel container. The horizontal keel supporting part 12 at the front end of the placement part 11 is provided with a jacking assembly that can adjust the supporting height. In this embodiment, the jacking assembly is two second jacking bolts 8, and the connecting piece A mounting plate 123 is provided on the transverse keel supporting part 12 of the main body 1, and the position of the mounting plate 123 is lower than the upper end surface of the transverse keel supporting part 12, and the two second jacking bolts 8 are installed vertically on the On the mounting plate 123, a second transverse keel cushion 4 is provided on the upper end of the second jacking bolt 8, and the ...

Embodiment 3

[0049] Figure 9 to Figure 11 Shows the third embodiment of the keel connection device for suspended curtain walls of the present invention, this embodiment is basically the same as Embodiment 1, the difference is that the connector body 1 of this embodiment is the same as the connector body in Embodiment 1 1 Compared with the vertical keel accommodating part 11, it is used for the curtain wall that does not need to be provided with the vertical keel 10, and the horizontal keel 2 is directly connected to the wall through fasteners after being leveled.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap