Dry-hung stone with enhanced mechanical property

A technology of dry hanging stone and performance, applied in covering/lining, construction, building structure, etc., can solve the problems of safety discount, noise and dust pollution, insufficient effective thickness of stone, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

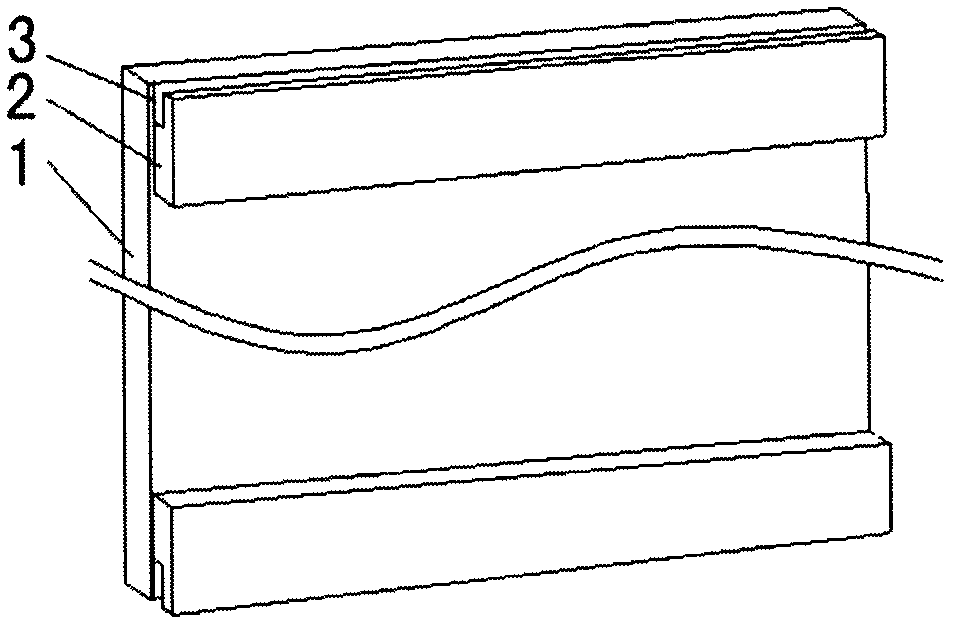

[0017] Example: such as figure 1 As shown, a dry-hanging stone material with enhanced mechanical properties includes a decorative stone plate 1, a mechanical property enhanced block 2 is bonded to the back of the decorative stone plate 1, and a mechanical property enhanced block 2 is also bonded to the bottom of the back.

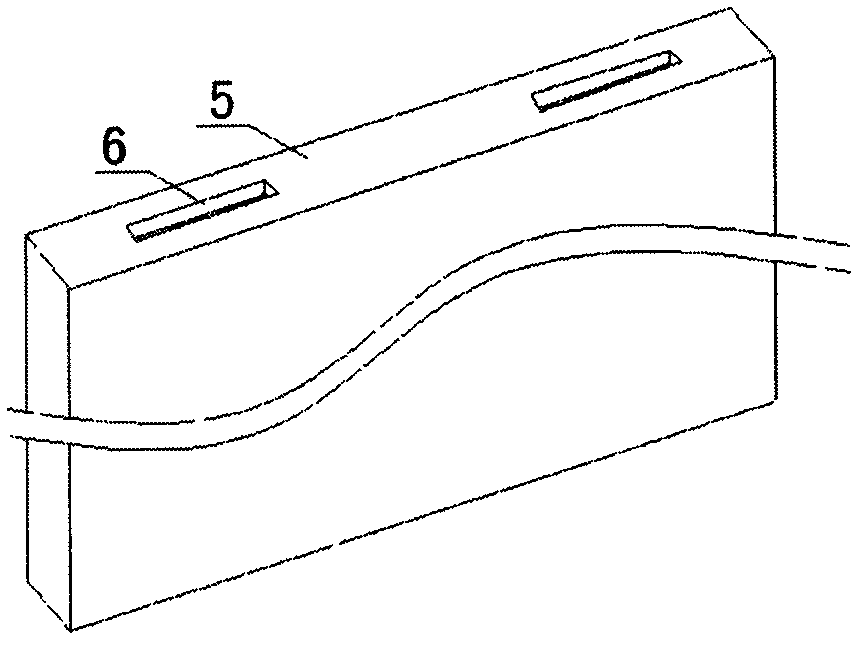

[0018] A notch 3 is provided on the mechanical performance enhancing block 2 . In this embodiment, a cutout 3 of 7 mm×25 mm is provided along the thickness direction of the long side of the mechanical performance enhancing block 2 during manufacture.

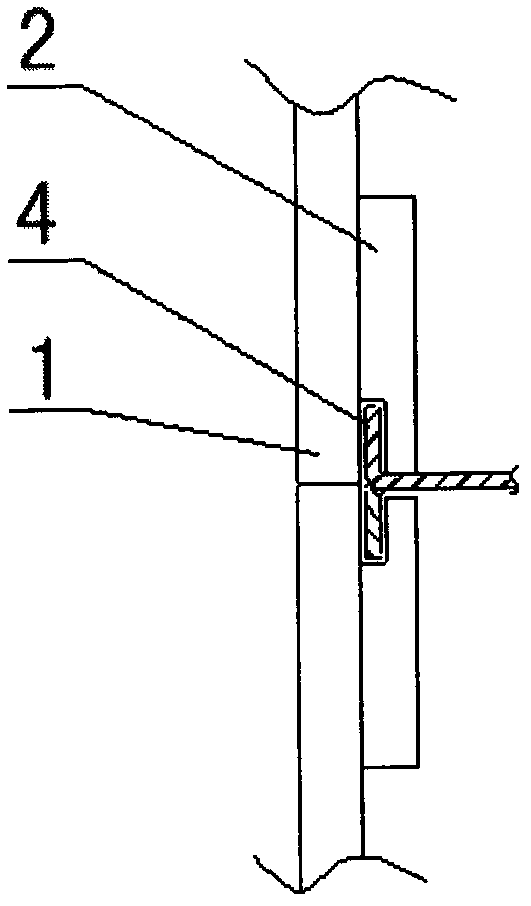

[0019] After the mechanical performance enhancing block 2 is effectively bonded to the decorative stone plate 1, a through groove is formed between its cutout 3 and the decorative stone plate 1, and the through groove is used to place a pendant 4 for dry-hanging stone (refer to image 3 ). The use of the mechanical performance enhancing block 2 can effectively reduce the thickness of the decorative stone pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com