Automatic door closing hinge with separate tension and speed adjustments

A technology of speed adjustment and automatic door closing, which is applied to door/window accessories, switches with braking devices, buildings, etc., and can solve problems such as high damage rate and complex structure of hydraulic door closers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further illustrate the present invention below in conjunction with accompanying drawing

[0024] Referring to the attached picture:

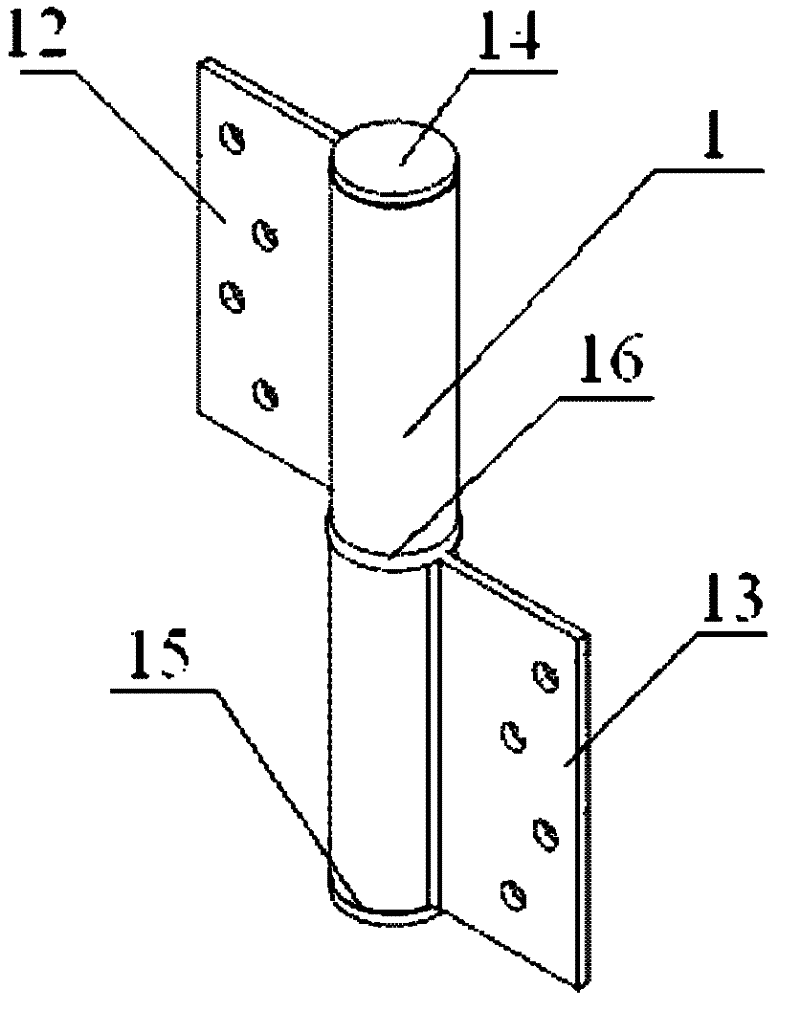

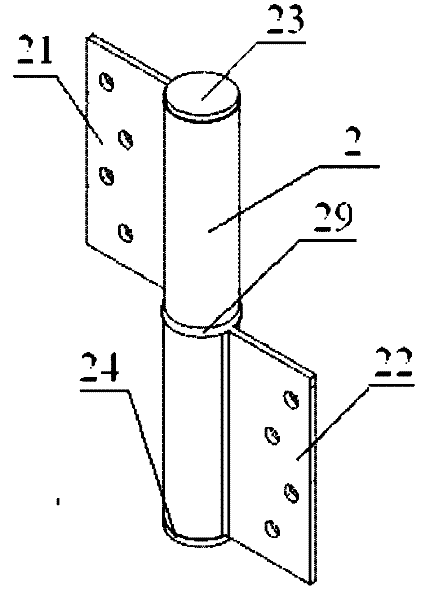

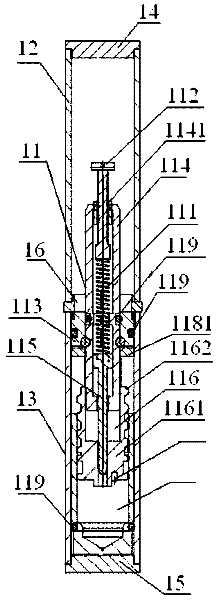

[0025] The self-closing combined hinge with separate tension and speed adjustment of the present invention includes a damping branch 1 and a spring branch 2, and the damping branch 1 includes a damping device 11, a first upper hinge 12, and a first lower hinge 13 , the first upper end cover 14, the first lower end cover 15 and the first plane bearing 16, the first plane bearing 16 is located between the first upper hinge 12 and the first lower hinge 13; the damping The device 11 includes a spring 111, a door closing speed adjusting screw 112, a ball base 113, a speed regulating shaft 114, a one-way valve spool 115, a piston 116, an orifice marble 117 and a hydraulic cylinder cavity 118. The door closing speed adjustment The screw 112 is installed in the shaft hole 1141 equipped with a sealing ring 1142 at the top of the speed regulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com