Electromagnetic valve automatically separating impurities

An automatic separation, solenoid valve technology, applied in the field of solenoid valves, can solve the problems of wasting water resources, manpower maintenance, pipeline tightness, etc., to avoid waste, save manpower consumption, and ensure the stability of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

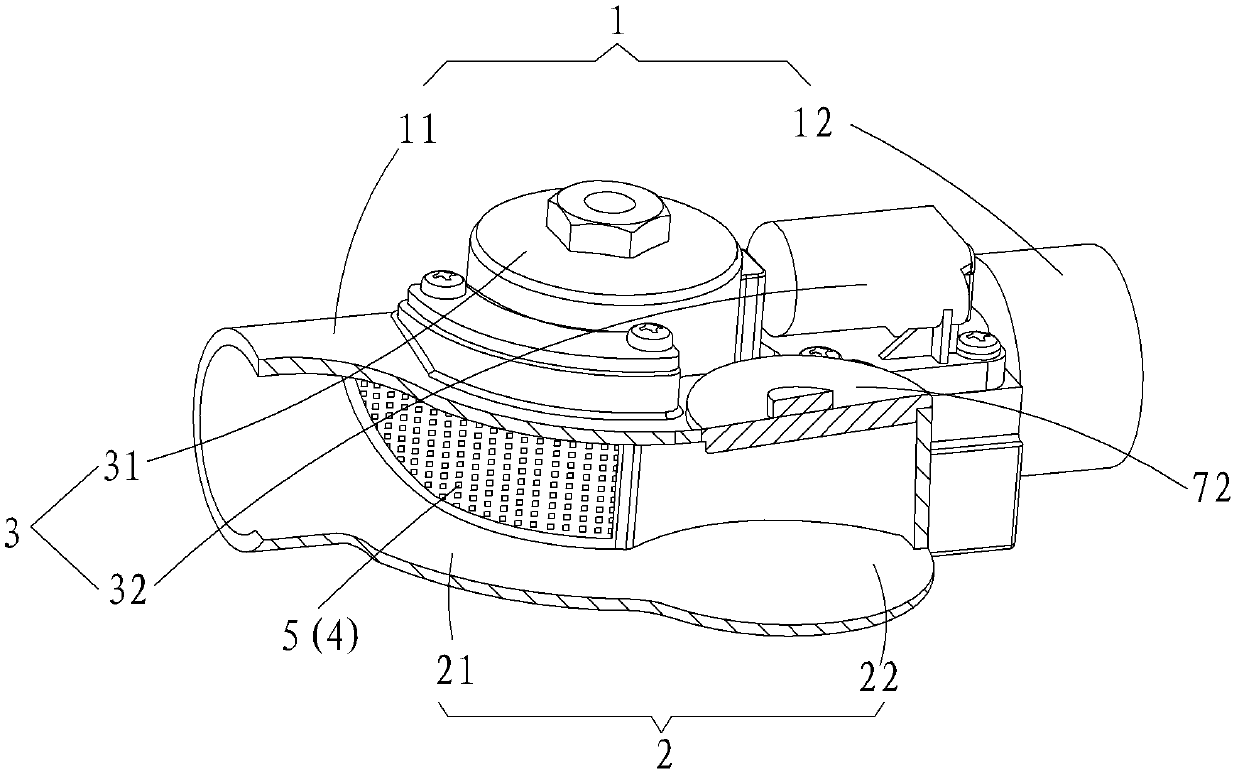

[0022] like figure 1 and figure 2 As shown, the electromagnetic valve of this embodiment includes a main pipeline 1, a pipeline 2, and a switch device 3 for controlling the opening or closing of the main pipeline 1, and the main pipeline 1 includes a water inlet 11 and a water outlet 12. The head end 21 of the branch pipe 2 and the water inlet end 11 of the main pipe 1 are connected and communicated through a first joint 4. The tail end 22 of the branch pipe 2 is a closed end, and the switch device 3 is located at the first joint. On the main pipe 1 between the junction 4 and the water outlet 12, the first junction 4 is provided with an arc-shaped filter screen 5, and the tail end 22 of the branch pipe 2 and the first junction 4 A manual slag removal unit 7 is provided, and the manual slag removal unit 7 includes a slag removal port 71 and a gland 72 for closing the slag removal port 71, the gland 72 is matched with the slag removal port 71, and the slag removal The port 72...

Embodiment 2

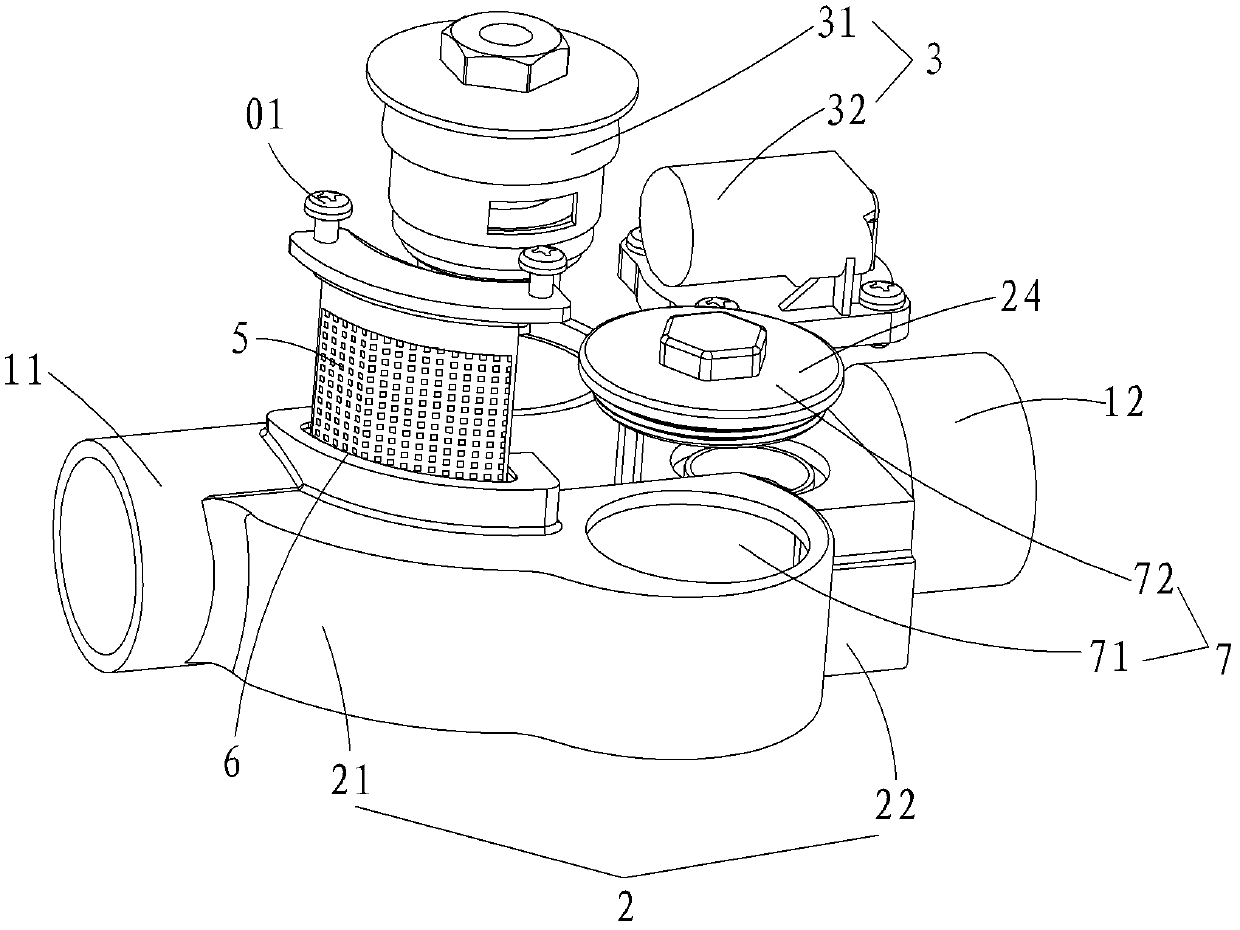

[0026] Please refer to image 3 and Figure 4 , the structure of the solenoid valve in this embodiment is compared with that of Embodiment 1, the difference is that in this embodiment, the slag cleaning unit used is not as figure 1 The shown manual slag removal unit 7 uses an automatic slag removal unit 8 instead; and the tail end 22 of the branch pipe 2 is connected and communicated with the water outlet 11 of the main pipe 1 through a second joint 9 . The automatic slag removal unit 8 includes a slag discharge valve body 81 and an electric control system 82 connected with the slag discharge valve body 81, and the slag discharge valve body 81 is arranged between the first junction 4 and the second junction 9 between. Among them, the electric control system 82 is used to control the opening or closing of the slagging valve body 81. The electric control system 82 can be set in advance so that it can open the slagging valve body 6 every once in a while, and set the slagging va...

Embodiment 3

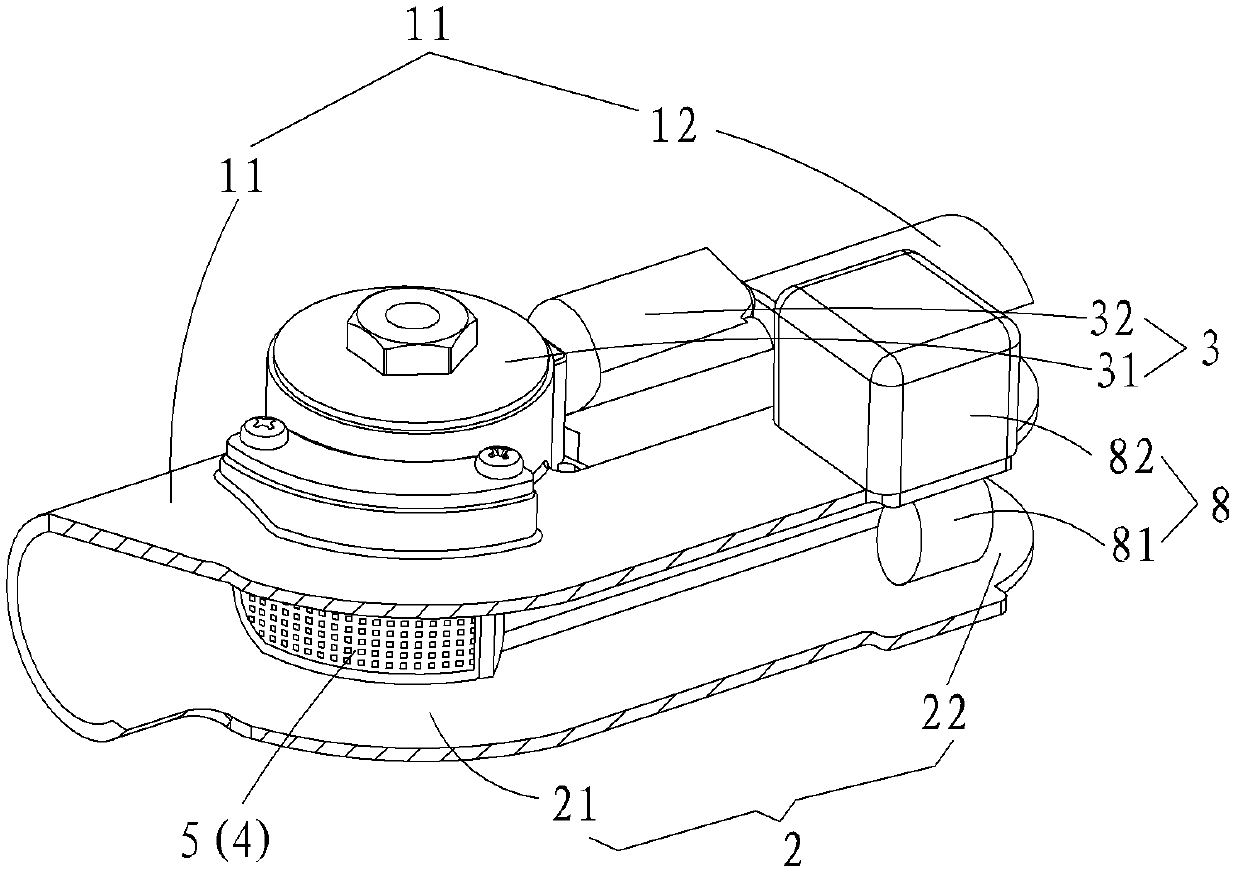

[0030] Please refer to Figure 5 and Image 6 , the structure of the solenoid valve in this embodiment is actually a combination of Embodiment 1 and Embodiment 2. Specifically, in this embodiment, two slag cleaning valves are provided between the tail end 22 of the branch pipe 2 and the first joint 4. unit, one of which is the manual slag removal unit 7 described in Embodiment 1, and the other slag removal unit is the automatic slag removal unit 8 described in Embodiment 2, and the slag removal unit 7 of the manual slag removal unit is The port 71 is located between the automatic slag cleaning unit 8 and the first connecting point 4 , and the tail end 22 of the branch pipe 2 and the water outlet end 12 of the main pipe 1 are connected and communicated through a second connecting point 9 .

[0031] In the application of this embodiment, when the automatic slag removal unit 8 can be used normally, the automatic slag removal unit 8 can be given priority to remove impurities accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com