Running water prevention device in disassembling self-sealing check valve and operation method thereof

An operation method and self-sealing technology, which is applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve the problems of site pollution, operator radiation contamination, water leakage, etc., and achieve safe and reliable use and fast recovery. The effect of installing and solving the problem of running water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technology of the present invention is further described below:

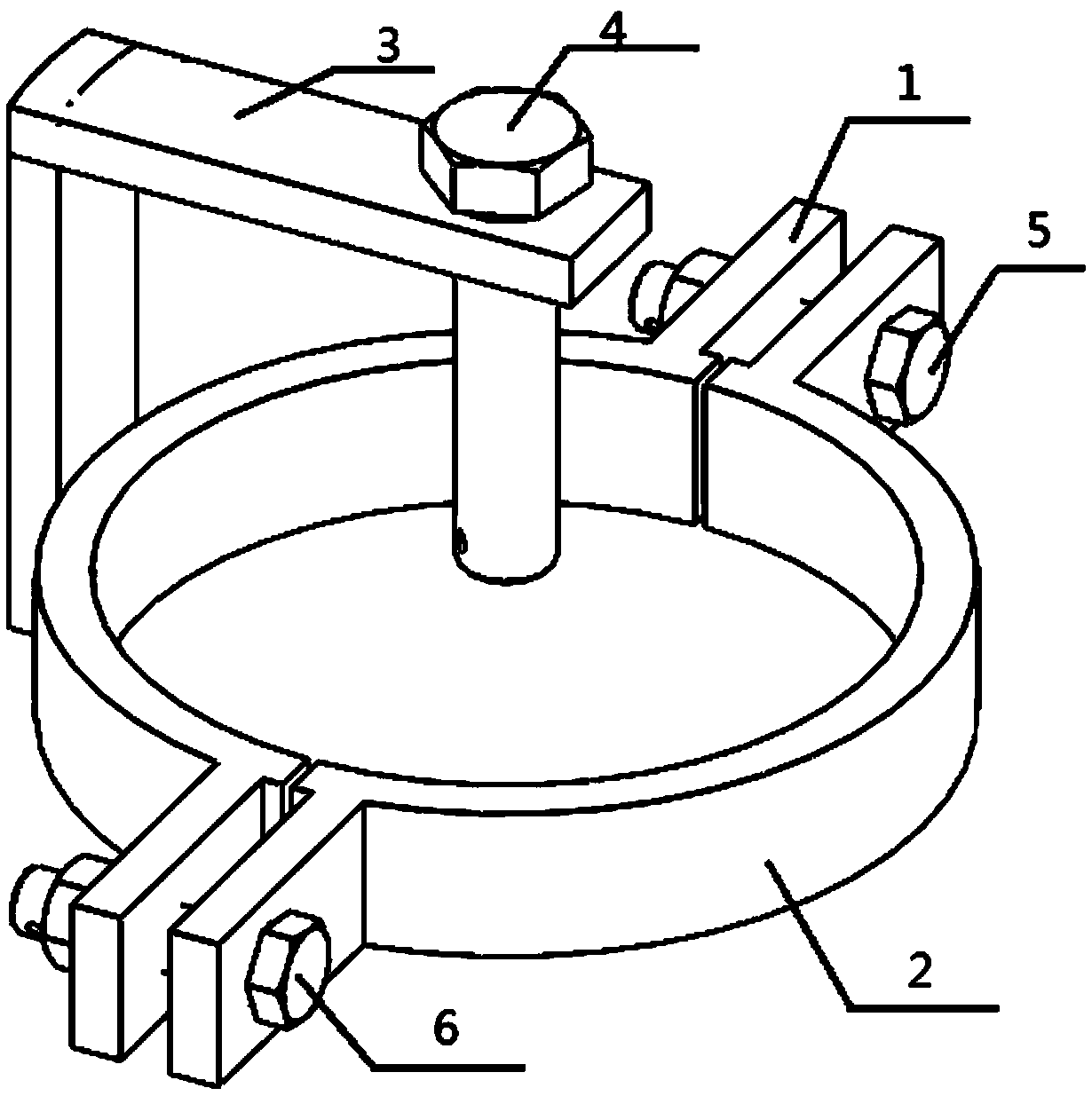

[0027] Such as figure 1 As shown, a self-sealing check valve anti-running device when unloading, including:

[0028] A self-sealing check valve anti-running device when unloading, comprising: snap ring A1, snap ring B2, limit bolt support arm 3, limit jacking bolt 4, fastening bolt A5 and fastening bolt B6; The snap ring A1 and the snap ring B2 are tightly connected by the fastening bolt A5 and the fastening bolt B6; the limit bolt support arm 3 is connected with the snap ring A1; the limit jacking bolt 4 is installed in the limit bolt support arm 3 .

[0029] Both the clasp A1 and the clasp B2 are of semicircular structure.

[0030] Both ends of the snap ring A1 and the snap ring B2 are provided with threaded through holes.

[0031] The inner diameters of the snap ring A1 and the snap ring B2 are the same and match the diameter of the valve body of the self-sealing check valve.

[0032] The limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com