Method for providing corrected pressure reference value for servo-controlled proportional valve, involves generating corrected pressure reference value using pressure reference value and correction value for given pressure reference value

A technology of pilot pressure and pilot valve, applied in the direction of fluid pressure actuation device, valve operation/release device, valve device, etc., can solve problems such as residual adjustment deviation and increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

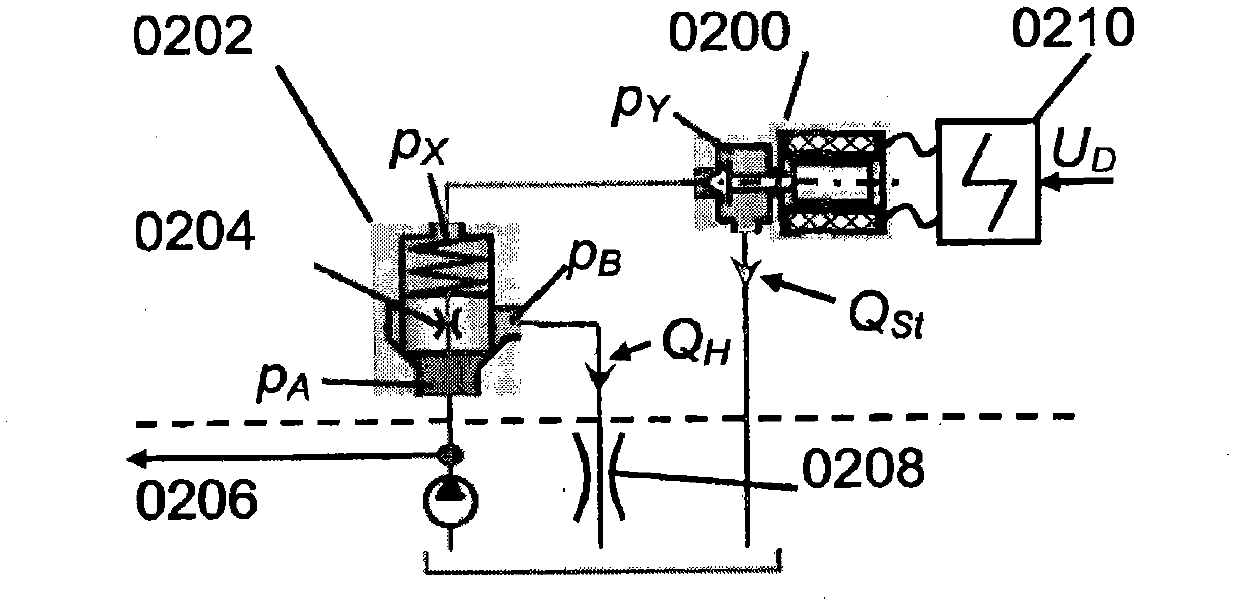

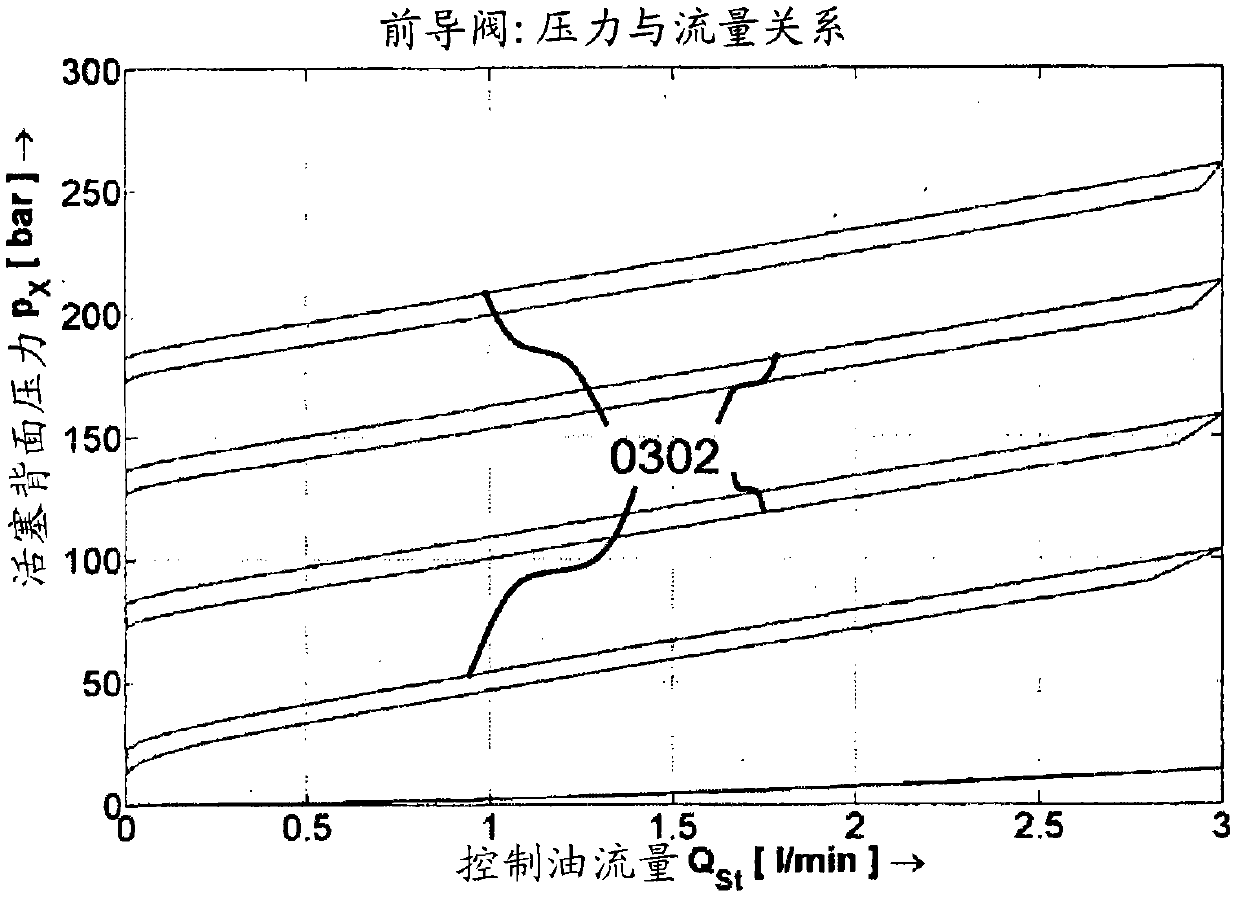

[0126] The same or similar reference numerals denote the same or similar elements in the figures described below. The figures, their descriptions, and the dependent claims also contain numerous features in combination. It is obvious to a person skilled in the art that these features can also be observed individually or they can also be combined into other combinations not explicitly described here. In addition, different dimensions and dimensions are used to explain the present invention in the following description, but the present invention should not be understood as being limited to these dimensions and dimensions. Furthermore, it is also possible to perform the method steps described in the present invention repeatedly and in a sequence different from that described. If a certain embodiment includes an "and / or" relationship between the first feature / step and the second feature / step, it can be understood that the embodiment described in one of the implementation modes not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com