Light source structure and backlight module

A technology of backlight module and light source, applied in the field of light source structure, to achieve the effect of convenient assembly and good electrostatic discharge protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

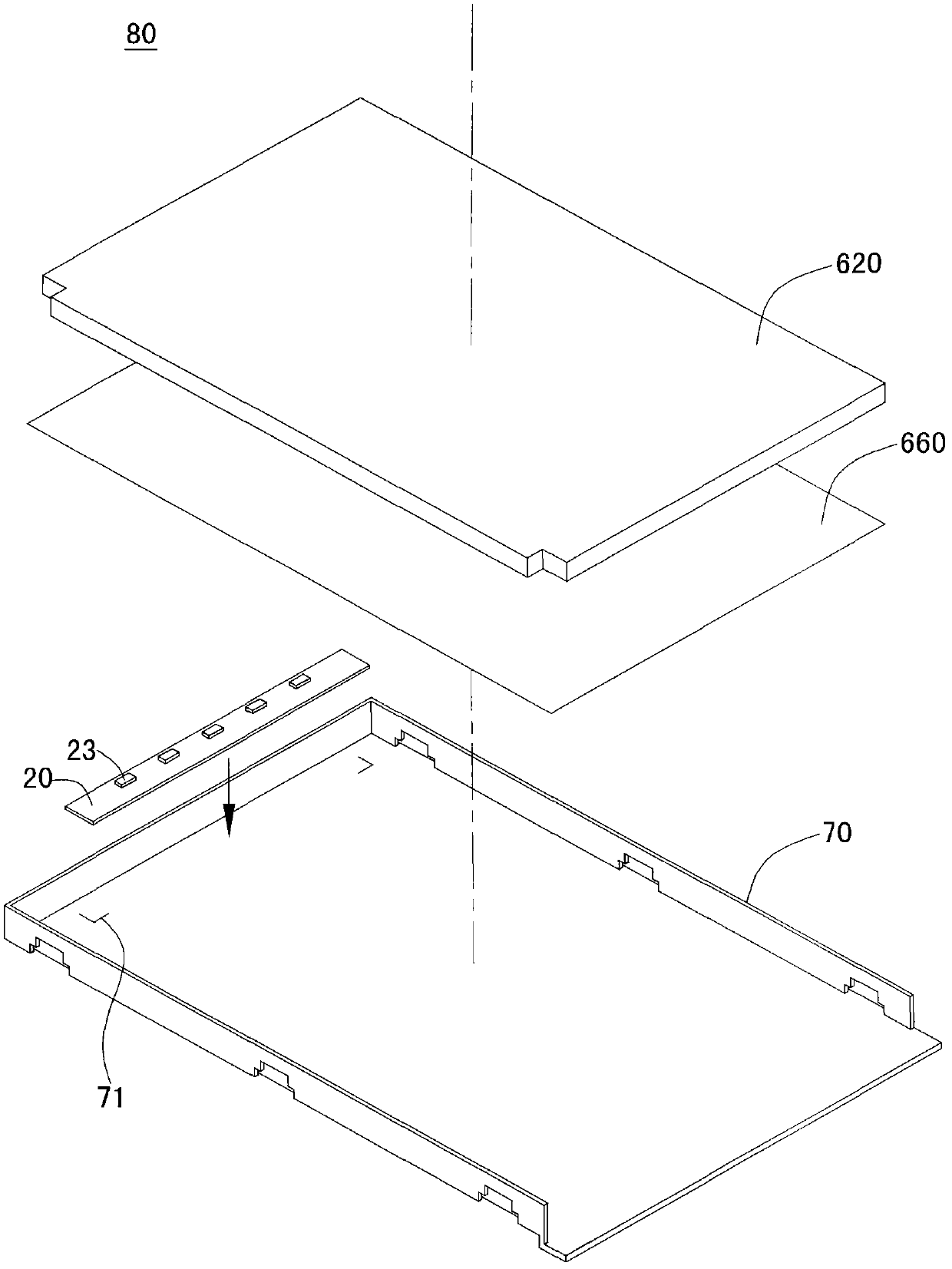

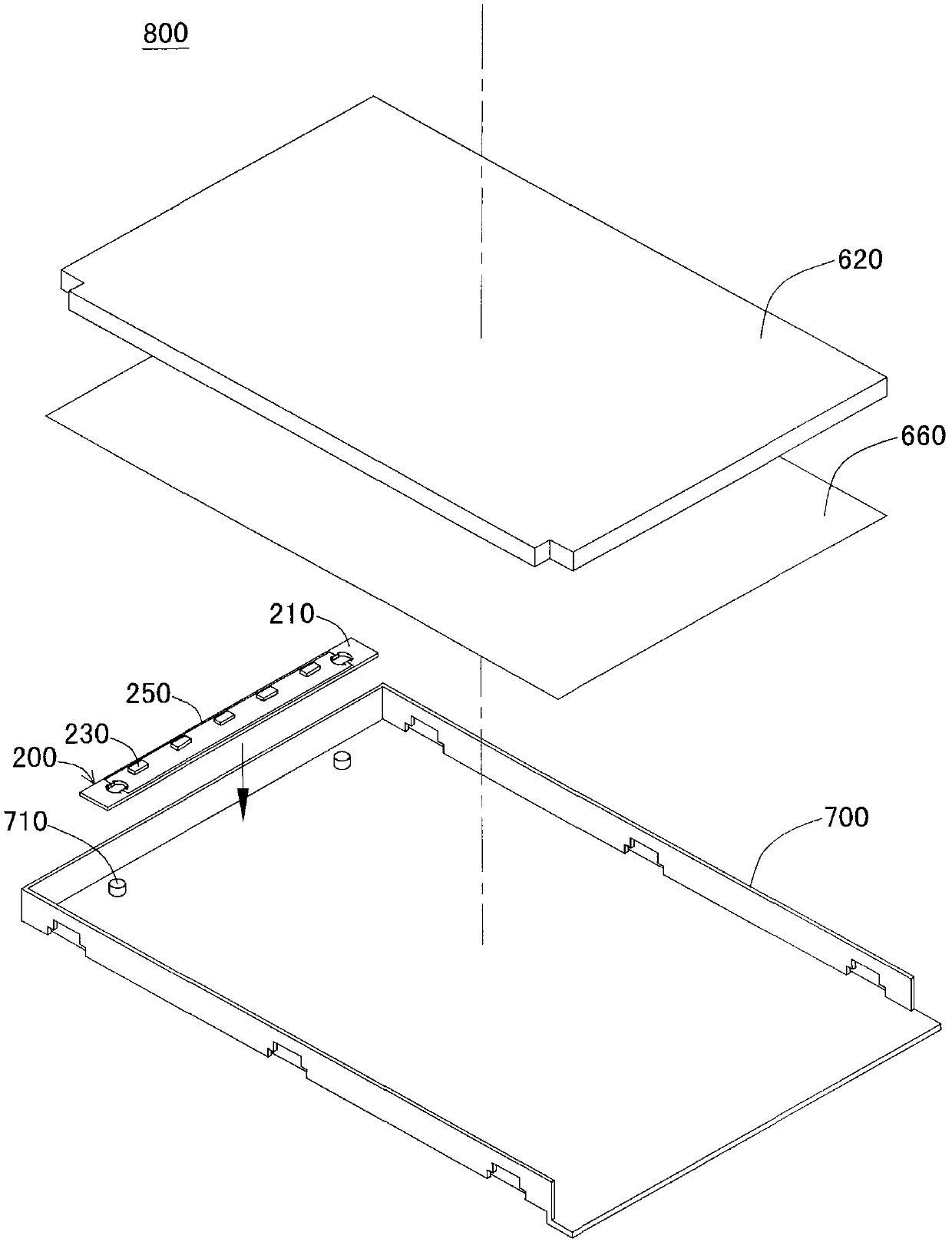

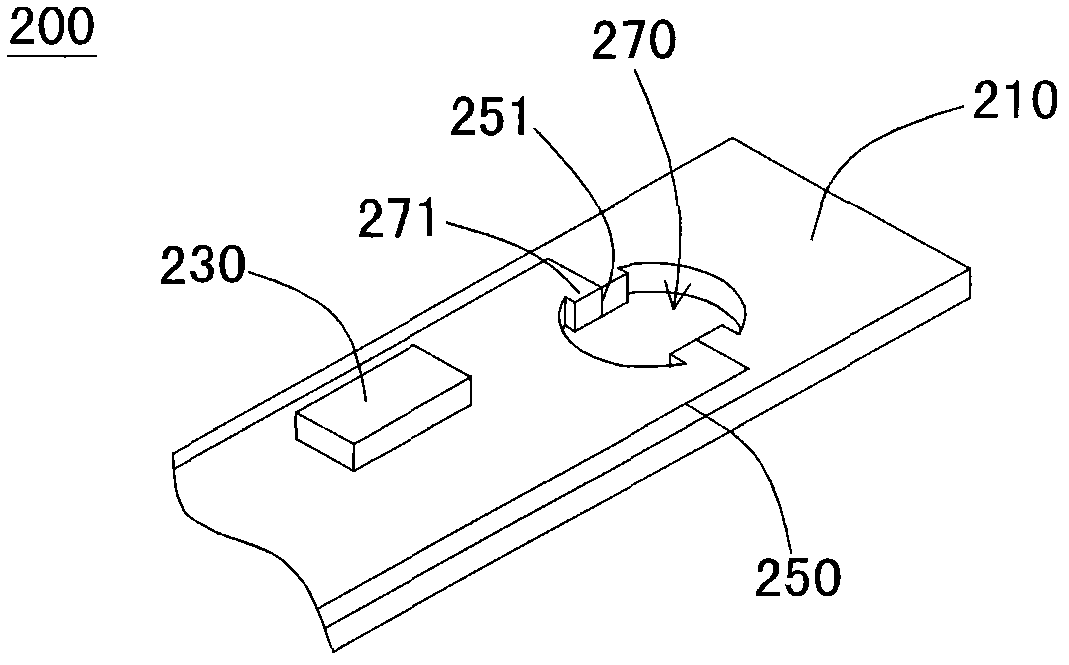

[0048] Such as figure 2 As shown in the exploded diagram of the backlight module, in a preferred embodiment, the light source structure 200 of the present invention can be used in the backlight module 800 . Specifically, the backlight module 800 includes a light source structure 200 and a metal backplane 700 , the metal backplane 700 has at least one metal protrusion structure 710 , and the light source structure 200 can be assembled on the metal backplane 700 through the metal protrusion structure 710 . In other words, the metal protrusion structure 710 can be used to assemble the light source structure 200 and the metal back plate 700 without first using such as figure 1 The shown alignment lines 71 are reassembled in alignment, which can improve the convenience of assembly and reduce deviation. Wherein, the metal protru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com