Tapping molten iron guiding device of induction furnace

A technology of induction furnace and guide device is applied in the field of guide device and guide device of molten iron for induction furnace, which can solve the problems of difficulty in popularization and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

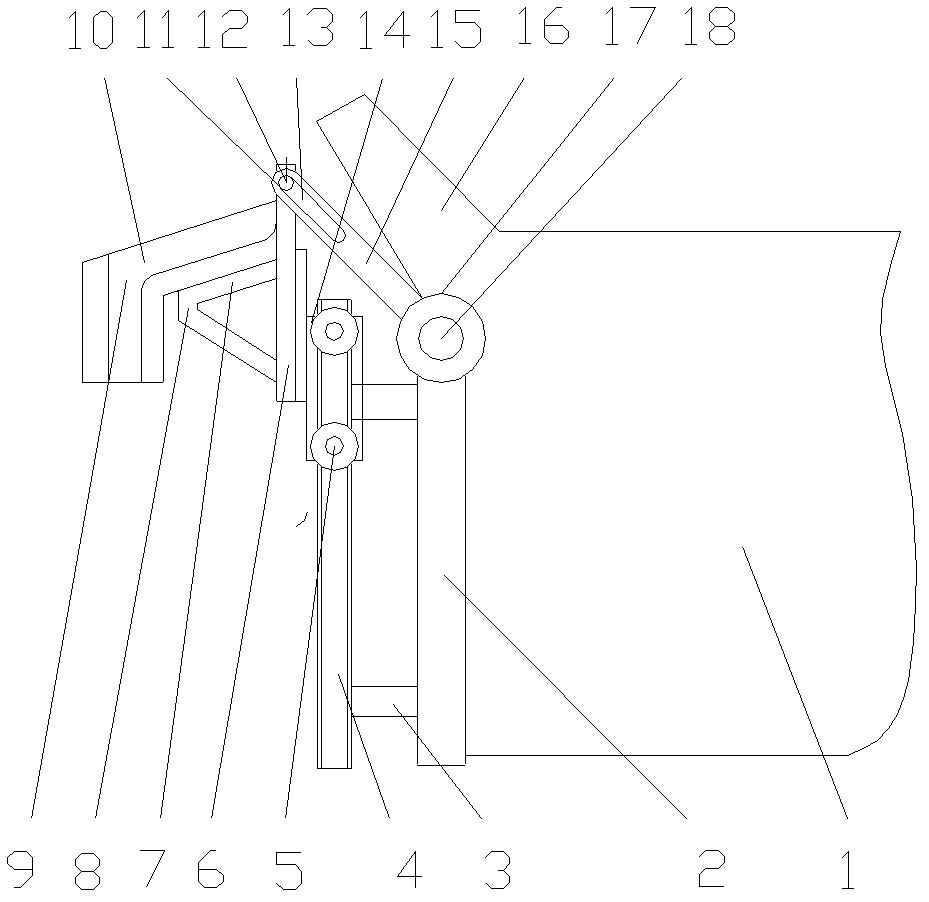

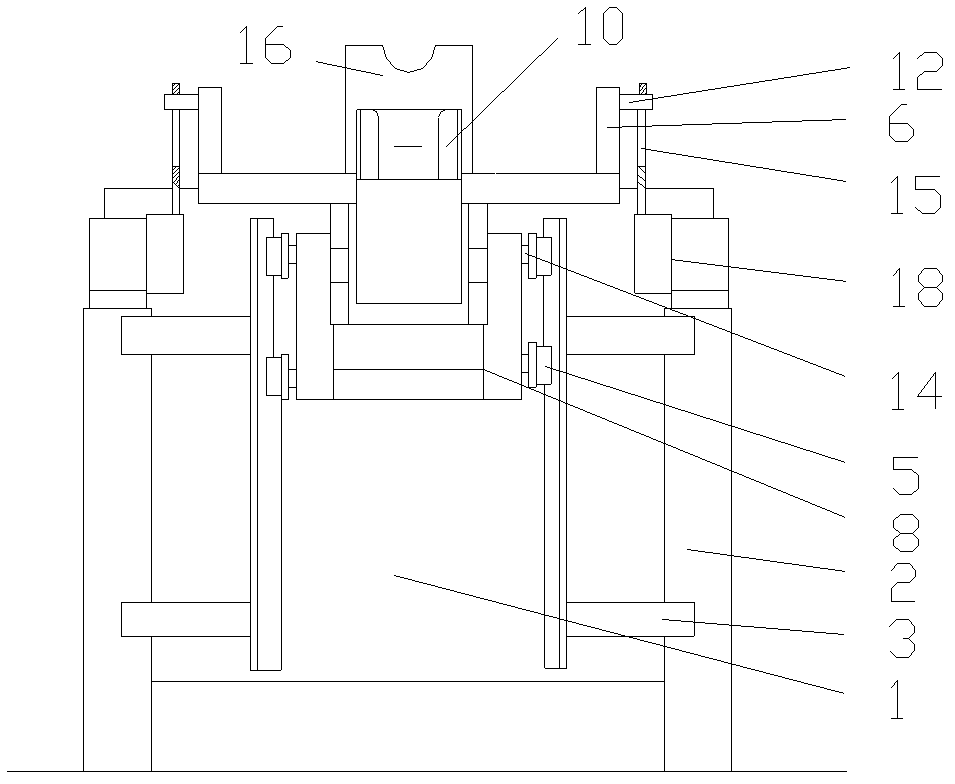

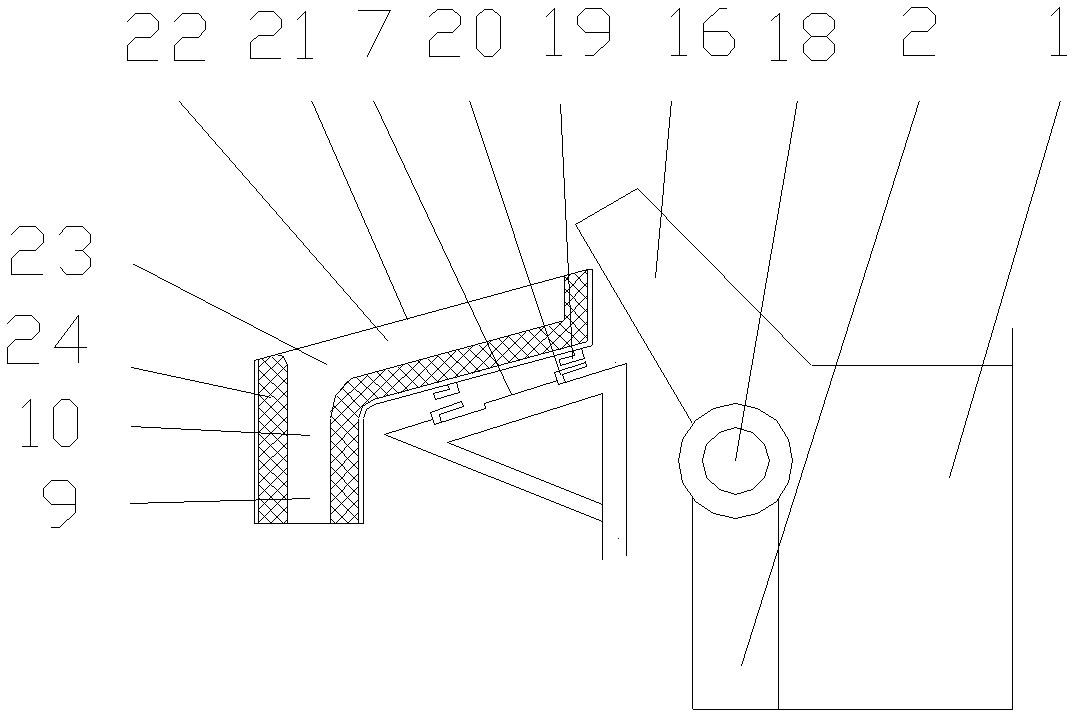

[0016] Now take a 1.5T induction furnace as an example to illustrate the specific implementation of the present invention in conjunction with the accompanying drawings. The utility model relates to a guide device for tapping molten iron in an induction electric furnace. Two furnace frame columns 2 are fixedly installed on the furnace wall in front of the induction furnace body of furnace 1 on both sides of the electric furnace nozzle 16 . A cross bar 3 is respectively installed on the upper half and the lower half of the two grate columns 2 . Two guide rails 4 with grooves are longitudinally affixed to the ends of two cross bars 3 on both sides. Bearings 18 are all installed on the tops of the two grate columns 2 . On the bearing casing 17 of two bearings 18, two fork bars 15 are fixedly installed, and two fork bars 15 can rotate around bearings 18. Two swing rods 15 are provided with long slots 13 for swing rods, and straight pins 12 are movably installed in the long slots...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap