Spheroidizing Treatment Method of High Nickel Ductile Iron

A nodular cast iron, spheroidizing treatment technology, applied in the spheroidizing treatment of high-nickel nodular cast iron, in the field of cast iron spheroidizing treatment, can solve the problem that the expected spheroidizing effect affects the spheroidizing quality stability of nodular iron castings, and increases equipment investment and maintenance Maintenance cost, poor on-site operating environment and other issues, to achieve the effect of reducing process cost, less temperature loss, and convenient operation

Active Publication Date: 2017-02-22

CRRC QISHUYAN INSTITUTE CO LTD +1

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] Second, because the spheroidizing agent is placed in the pit at the bottom of the ladle, the contact between the spheroidizing element magnesium (including lumps, wires, etc.) It is difficult to achieve the expected spheroidizing effect after ironing, which directly affects the stability of the spheroidizing quality of the nodular iron casting

[0007] Third, the on-site operating environment is poor and the safety is low

Since nodulizers and inoculants are placed in the pit of the ladle, it must be carried out under the condition that the ladle is fully baked (temperature > 850°C), and the height of the ladle is relatively high (the height-to-diameter ratio of the ladle is generally higher than that of the ladle). ≥1.5), the workers have to brave the heat and get close to the ladle before the spheroidizer, inoculant and covering agent can be layered and arranged in the pit of the ladle in sequence, and a steel plate should be added to the surface to seal it, so The whole operation process is very troublesome and arduous, and there are greater safety risks

[0008] The 4th, owing to the described flushing method of prior art, press-in method and wire feeding method, necessary device will be equipped with, thereby also increased equipment investment and maintenance cost

[0010] Based on the spheroidization treatment method of the prior art, there are many shortcomings such as poor on-site working environment, high process cost, low safety and unstable casting quality, and a new spheroidization treatment method is developed to Overcoming the shortcomings of existing technologies has become the expectation of the industry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0047] Adopt the technical scheme of the specific implementation steps described in the present invention, carry out specific implementation in the laboratory. The detailed specifications or dosages of various raw materials or reagents used in the method of the present invention are only for illustration, and do not constitute a limitation to the technical solution of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Login to view more

Abstract

The invention discloses a spheroidising method of high-nickel nodular cast iron. The method is characterized in that a medium-frequency furnace is adopted to carry out melting, spheroidising is performed in a melting furnace, and a casting ladle whose bottom contains a technological amount of inoculant is adopted to carry out an inoculant treatment; and has the characteristics of reasonable method, convenient operation, safe environment, and good quality of finished product. The method is a novel technology for carrying out spheroidising by throwing a spheroidising agent in a furnace.

Description

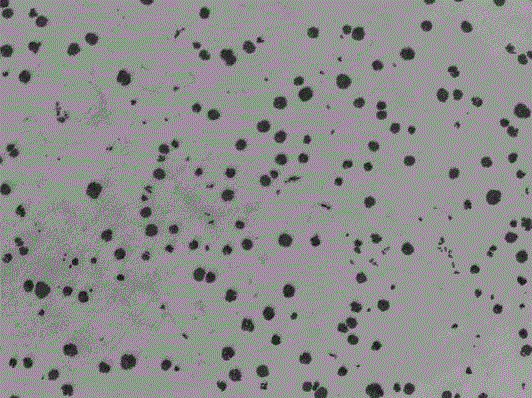

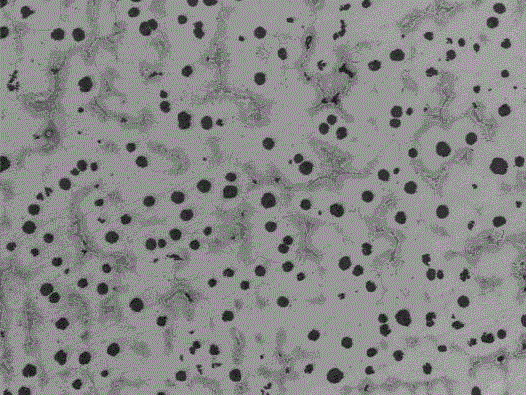

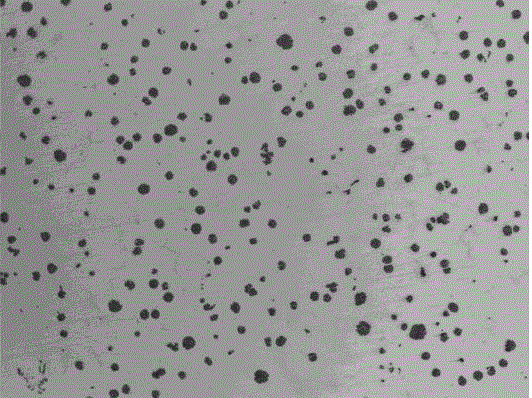

technical field [0001] The invention relates to a spheroidizing treatment method of cast iron, in particular to a spheroidizing treatment method of high-nickel nodular cast iron, which belongs to the technical field of casting production. Background technique [0002] High nickel ductile iron refers to a type of alloy ductile iron whose nickel content is in the range of 13~38%. Usually in its chemical composition, the carbon content is ≤4.0%, the nickel content is 13~38%, and the residual magnesium content is 0.03~0.09% (weight percentage); its metallographic structure is austenite and partial carbide and Spheroidal graphite, pearlite and ferrite may also be present. Because of its high mechanical properties at room temperature, excellent thermal shock resistance and thermal creep resistance, excellent high temperature oxidation resistance and corrosion resistance, and low thermal expansion and good low temperature impact toughness, so It has broad application prospects in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Patents(China)

IPC IPC(8): C22C33/08C21C1/10

Inventor 张俊新唐中权喻光远

Owner CRRC QISHUYAN INSTITUTE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap