Ladle for spheroidizing and manufacturing process thereof

A technology of spheroidization treatment and manufacturing process, which is applied in the direction of manufacturing tools, metal processing equipment, casting molten material containers, etc., can solve the problems affecting cost and spheroidization quality, high production cost, high process requirements, etc., and achieve excellent spheroidization effect , The effect of low manufacturing difficulty and low height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

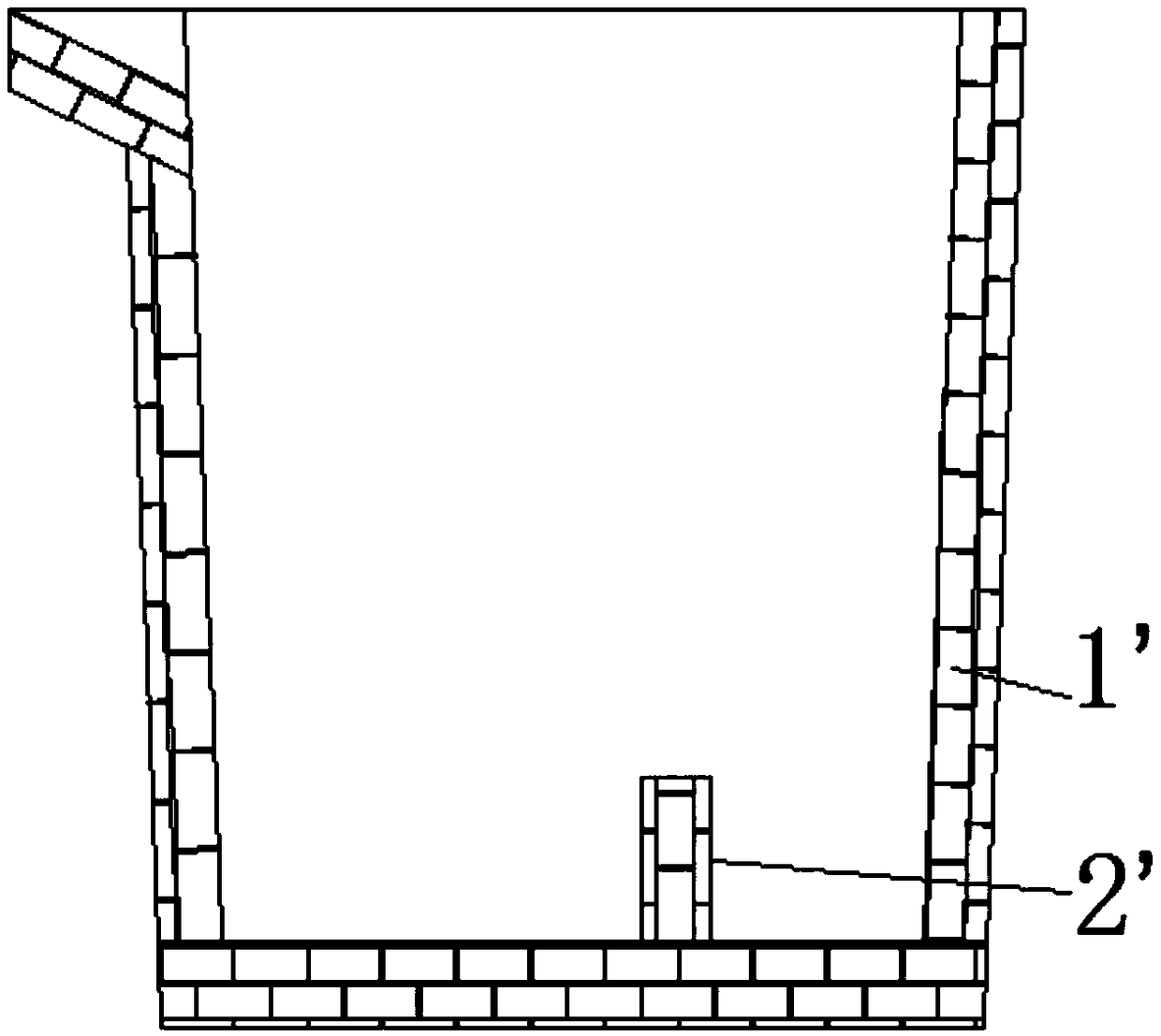

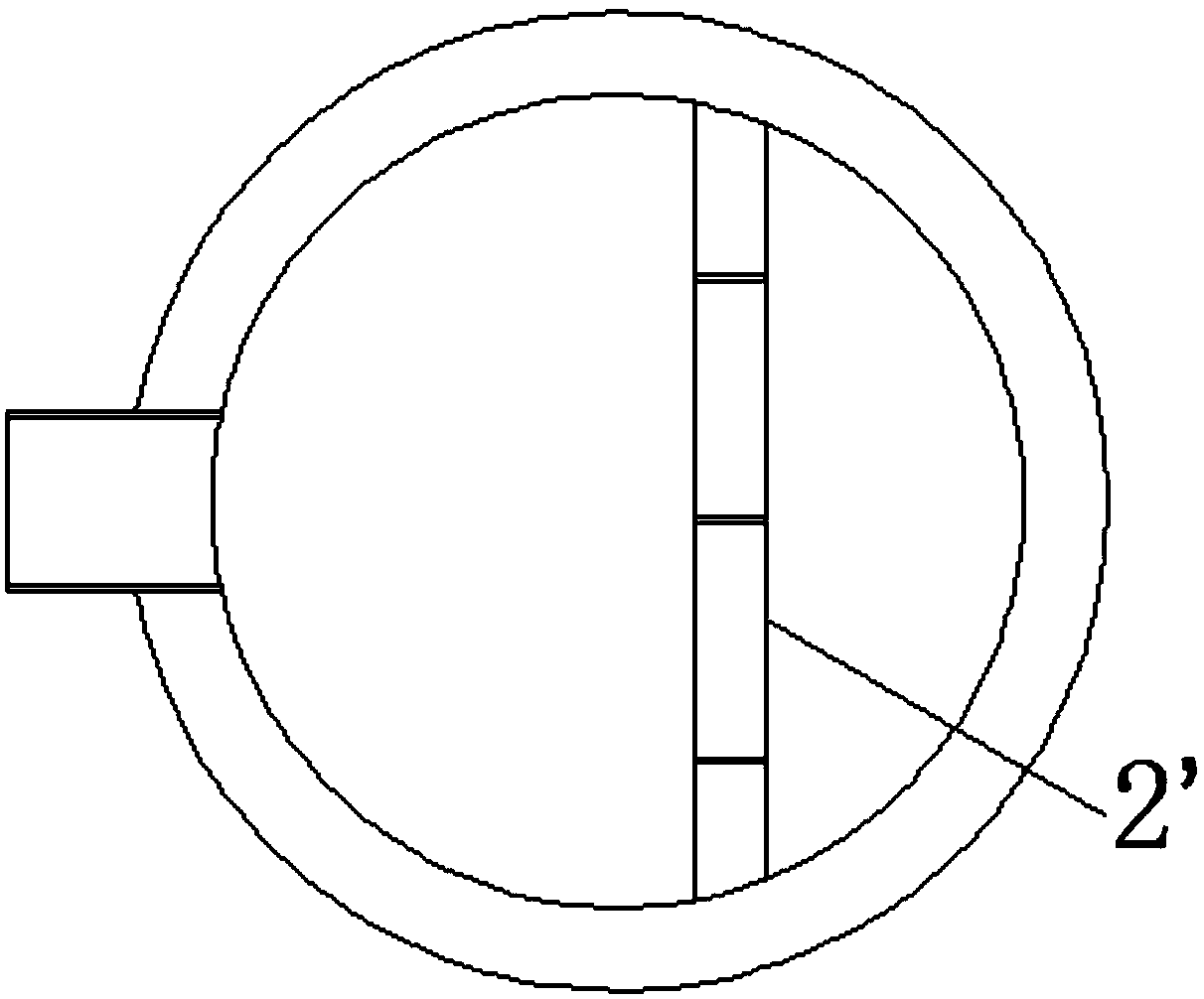

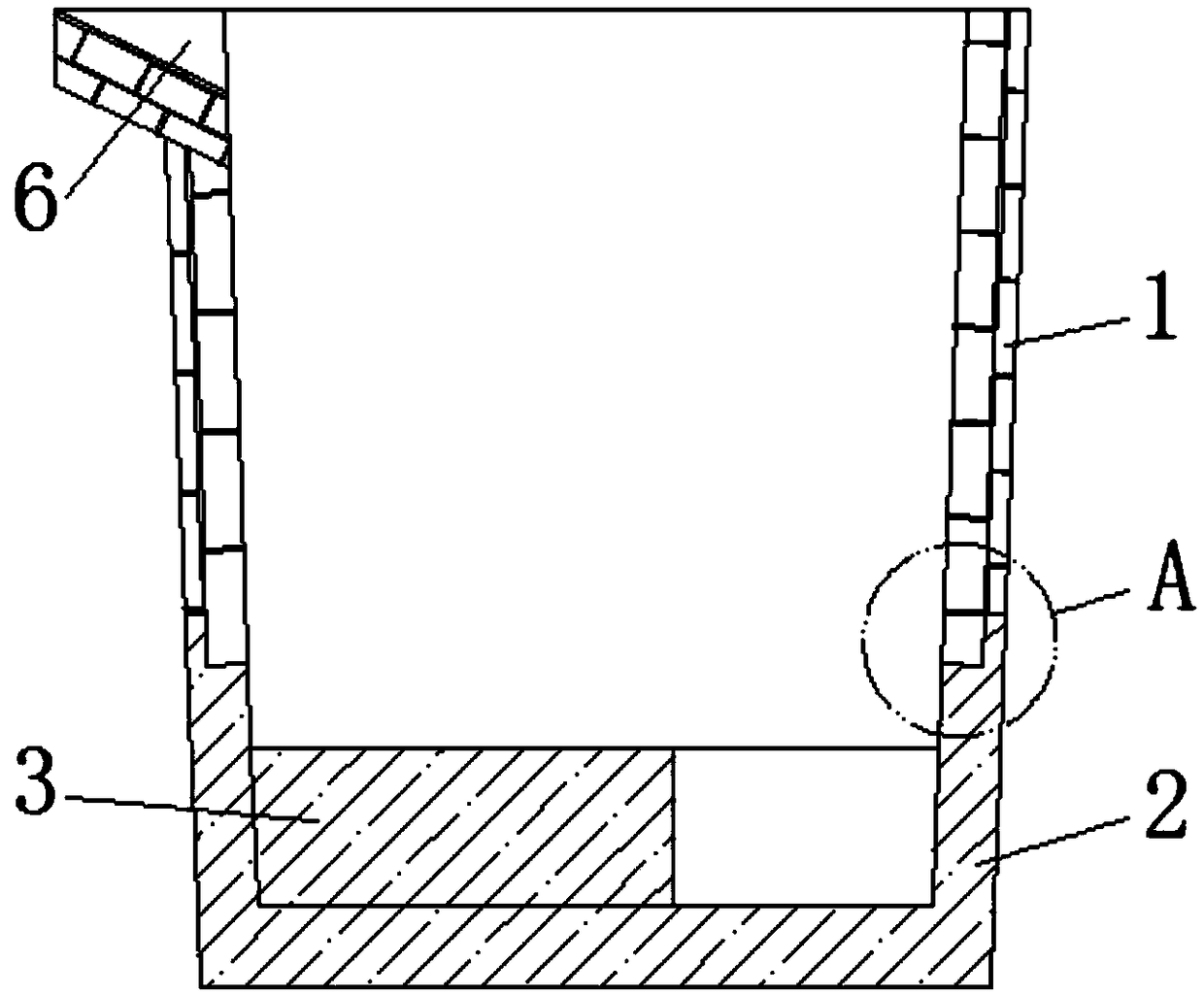

[0048] refer to Figure 3-5 As shown, a ladle for spheroidizing treatment of the present invention includes an upper side wall 1 built with refractory bricks and a spheroidizing chamber 2 cast with castables, the lower part of the upper side wall 1 and the side of the spheroidizing chamber 2 The upper part of the wall is sealed and connected, and the spheroidizing chamber 2 includes a dam 3 located on the inside of the bottom, and the inside of the spheroidizing chamber 2 is divided into a buffer pit 4 and a nodulizing agent placement pit 5 .

[0049] A ladle for spheroidization treatment according to the present invention, its upper side wall 1 is built with traditional refractory bricks, and the spheroidization chamber 2 formed by pouring castables, the inner side of the bottom of the spheroidization chamber 2 is a dam 3 , the embankment 3 divides the inside of the spheroidizing chamber 2 into a buffer pit 4 and a nodulizer placement pit 5. During pouring operations, molten ...

Embodiment 2

[0073] Such as Figure 6 As shown, the ladle for spheroidizing treatment in Example 2 of the present invention is basically the same as that in Example 1, and it includes all the features of the ladle for spheroidizing treatment in Example 1. In addition, the middle part of the embankment 3 and the part of the embankment 3 located on one side of the buffer pit 4 are higher than the rest. When treating molten iron by spheroidization, because the part of the embankment 3 located on one side of the buffer pit 4 is higher, the molten iron will flow from the other side of the buffer pit 4 to the nodulizer placement pit 5, and the middle part of the embankment 3 is also higher, and the molten iron will Sequentially flow through a plurality of nodulizer placement pits 5 for effective nodularization. Before the molten iron enters the molten iron ladle for nodulizing treatment, the nodulizing agent is put into a plurality of nodulizing agent placement pits 5 along the molten iron flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com