Variable multi-point locating cylinder barrel deformation testing clamp and testing method

A multi-point positioning and measuring fixture technology, which is applied in the direction of measuring devices, manufacturing tools, workpiece clamping devices, etc., can solve problems such as inability to complete the measurement at one time, affecting measurement accuracy, and cylinder deformation, so as to shorten the development cycle and save Prototype costs and the effect of reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

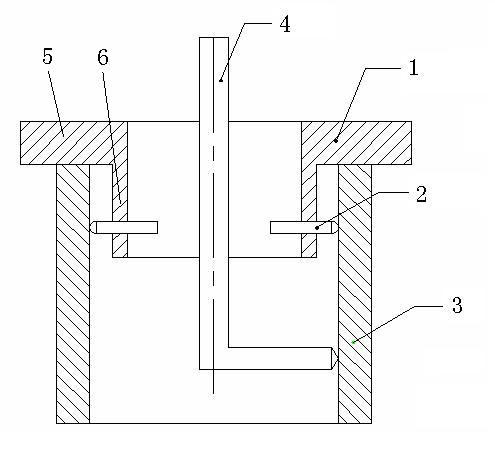

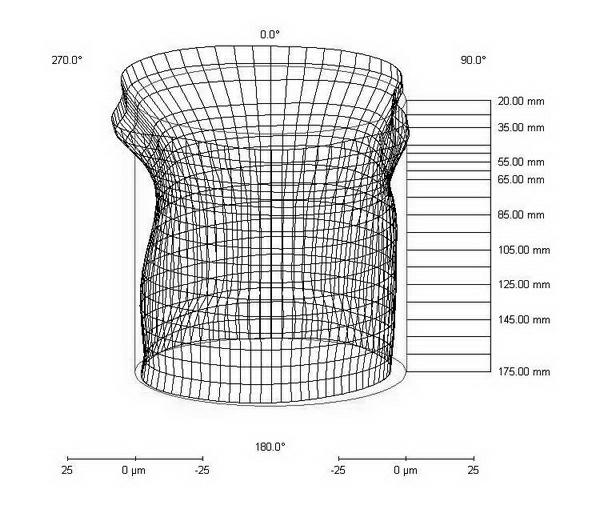

[0017] The clamp 1 of the present invention is composed of a rim 5 and a cylinder 6, on which an adjusting screw 2 is installed. The measuring instrument 4 is concentrically installed on the fixture 1, and then placed in the cylinder 3 for measurement.

[0018] The measurement method of fixture of the present invention is:

[0019] a. The rotating ring gear of the measuring instrument drives the positioning claw to expand or contract inward, and the measuring instrument is "squeezed" into the fixture by applying a certain clamping force, and is clamped with the fixture, and the center of the measuring instrument is coaxial with the center of the fixture;

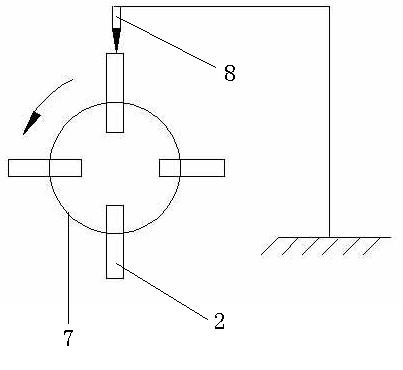

[0020] b. Install the fixture on the three-jaw chuck of the indexing plate, rotate the chuck and use the altimeter to measure the unscrewing height of the adjustment screw; the height measurement process is: install the fixture on the three-jaw chuck of the indexing head , the clamping process is automatically centered to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com