Light hydrocarbon density instrument and method for measuring light hydrocarbon density by adopting light hydrocarbon density instrument

A technology of density meter and light hydrocarbon, which is applied in measuring devices, specific gravity measurement, instruments, etc., can solve the problems of broken glass hydrometer, complicated calculation method, high price, etc. The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

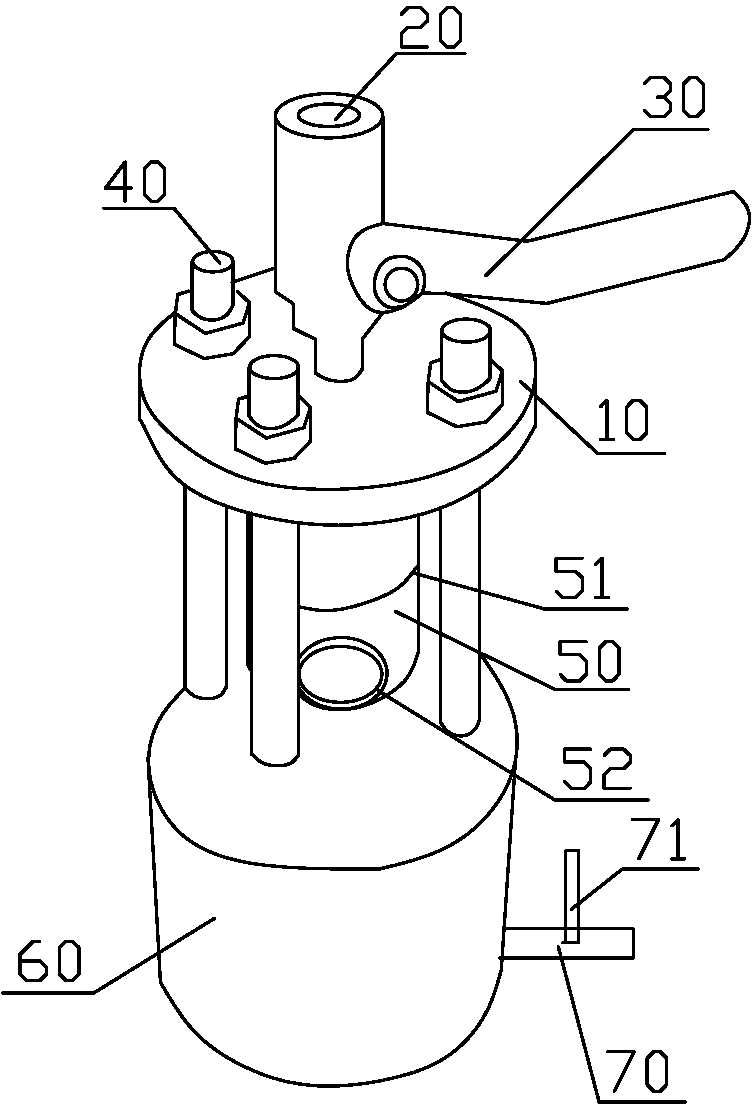

[0025] Such as figure 1 As shown, the light hydrocarbon density meter of this embodiment includes two parts: a tester and an electronic scale. Among them, the tester such as figure 1 , comprising an end cover 10, a liquid inlet barrel 60, a transparent measuring tube 50 tightly connected between the end cover 10 and the liquid inlet barrel 60, the upper end of the end cover 10 is provided with a liquid outlet communicating with the top of the transparent measuring tube 50 The exhaust port 20 and the liquid outlet valve 30 used to control the on-off of the liquid outlet and exhaust port 20, the bottom or side of the liquid inlet barrel 60 is provided with a liquid inlet 70 and is used to control the on-off of the liquid inlet 70 The liquid inlet valve 71, the end cover 10 and the liquid inlet barrel 60 are fixed by four uniformly arranged screw rods 40, and the top and bottom of the transparent measuring tube 50 are provided with O-shaped valves for preventing liquid leakage. ...

Embodiment 2

[0032] This embodiment provides a method for measuring the density of light hydrocarbons using the light hydrocarbon density meter described in Embodiment 1, comprising the following steps:

[0033] Step 1: Place the tester marked with the scale line 51 on the electronic scale to weigh, and then click the "tare" function button of the electronic scale to tare, so that the electronic scale displays zero;

[0034] Step 2: Connect the outlet of the light hydrocarbon liquefied gas to be measured to the liquid inlet 70 through a transparent high-pressure rubber hose, and open the liquid inlet valve 71 at the same time, so that the measured liquid is injected to reach the scale line, and close the liquid inlet valve 71;

[0035] Step 3: Place the tester on the electronic scale to weigh, read the mass displayed on the electronic scale, if the mass unit is gram (g), the read mass value / 1000 is the liquid density, if the mass unit is Kilogram (kg), the mass value read is the density va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com