Processing box and image forming device

A technology for processing cartridges and images, which is applied to equipment for electric recording technology using charge patterns, electric recording technology for applying charge patterns, and electrography, etc., and can solve the problem of affecting the positioning accuracy of the processing cartridge 10 and the separation of the processing cartridge 10 from the installation position , high spring performance requirements and other issues, to achieve the effect of increasing stability, reducing requirements, and improving image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

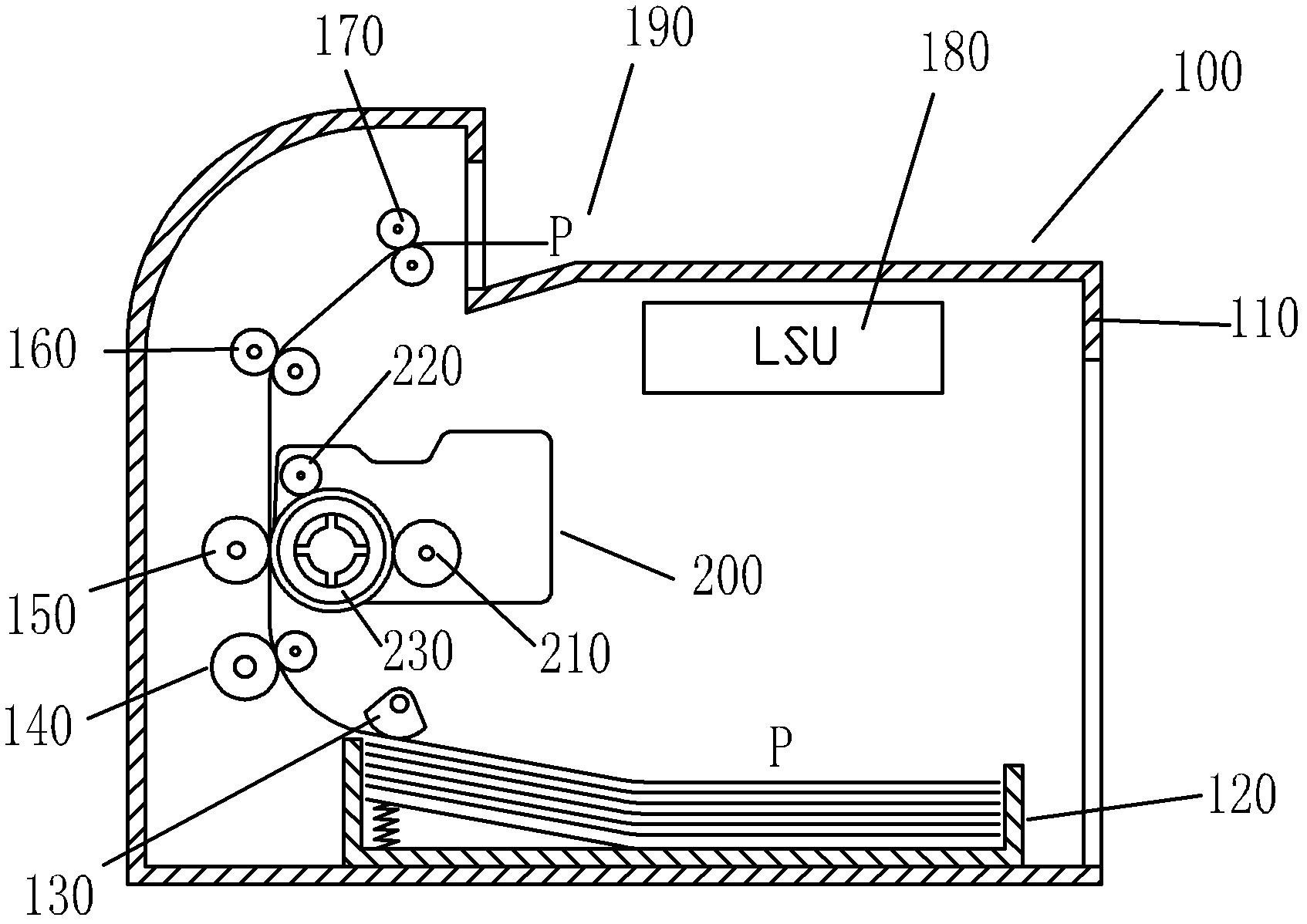

[0033] image 3 A schematic diagram of the structure of the process cartridge installed in the image forming apparatus provided by the embodiment of the present invention. The image forming apparatus may be of any type, such as a printer, a copier, etc., which require a process cartridge to be installed. This embodiment is specifically based on image 3 The typical structure shown is taken as an example for explanation.

[0034] Such as image 3 As shown, the image forming apparatus is a laser printer 100, which includes a main frame 110, a paper supply tray 120 accommodated in the main frame 110 and capable of storing a plurality of printing media P, a paper feeding device 130, a conveying roller 140, a fixing unit 160 , a discharge unit 170 , a transfer roller 150 , and a laser scanning unit (LSU) 180 , and a discharge tray 190 is provided on the upper surface of the main frame 110 . The process box 200 is detachably installed in the laser printer 100 , and the process b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com