Electric connector shielding structure and producing method

A technology of electrical connectors and shielding structures, which is applied in the direction of connecting parts, protective grounding/shielding devices, connections, line/collector parts, etc., which can solve the problems of shortening the service life of cover plates, fewer types of conductive plastics, and affecting shielding effects, etc. , to reduce weight, high processing efficiency and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they are not further limitations on the present invention.

[0022] The shielding structure and manufacturing method of the electrical connector provided by the present invention are applicable to various electrical connectors for transmitting signals.

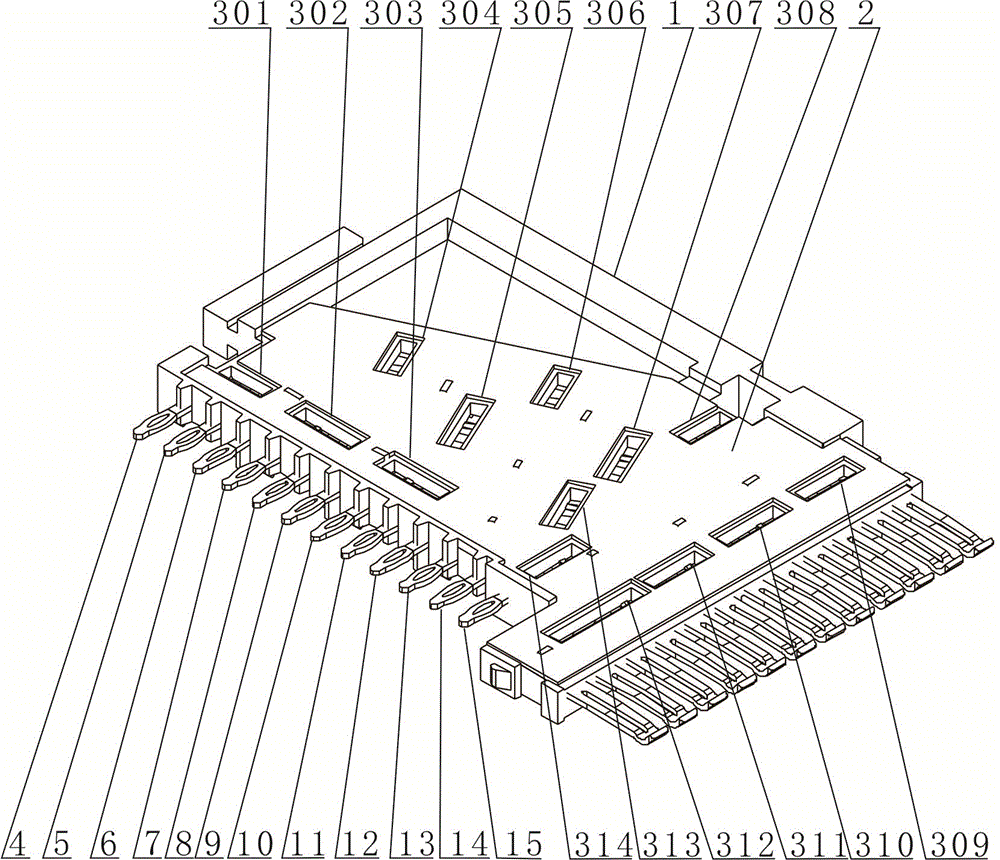

[0023] This embodiment takes figure 1 The illustrated electrical connector is taken as an example to describe the shielding structure provided by the present invention in detail.

[0024] Such as figure 1 As shown, the electrical connector includes a contact, a plastic base 1 disposed outside the contact, and an electroplating layer 2 disposed on the outer surface of the plastic base 1 .

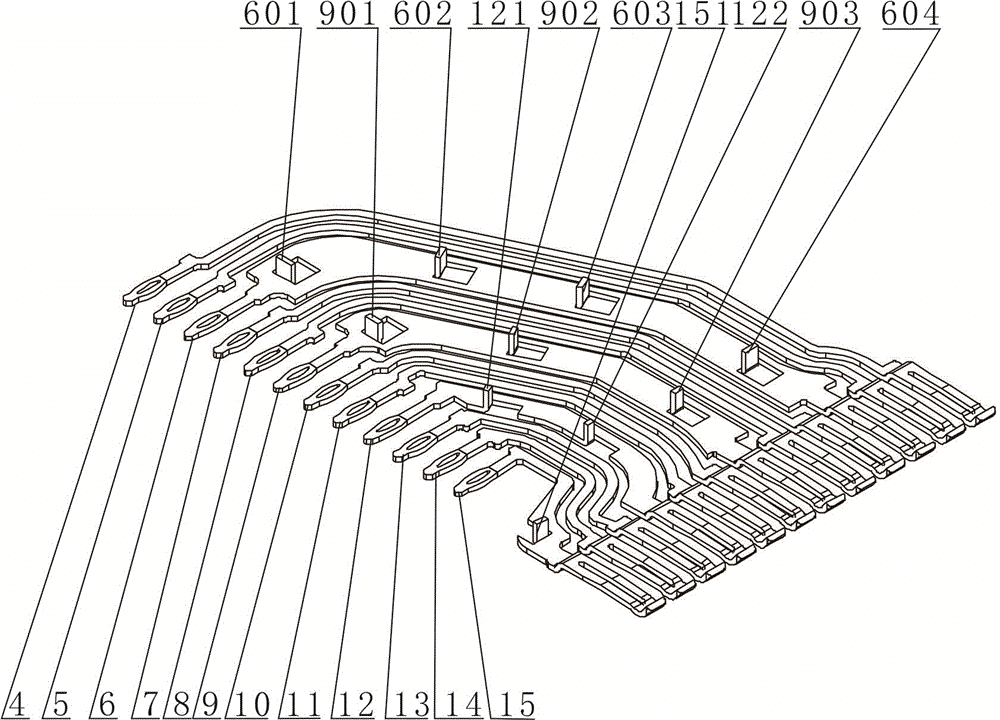

[0025] Such as figure 2 As shown, the contacts of the electrical connector include signal contact a4, signal contact b5, ground contact a6, signal contact c7, signal contact d8, ground contact b9, signal conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com