Busbar-free high-efficiency back-contact solar cell, module and its preparation process

A technology for solar cells and solar cells, applied in the field of solar cells, can solve the problems of inability to realize, corrode, increase in series resistance, etc., and achieve the effects of reducing the difficulty of series connection, reducing the transmission distance, and reducing the series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

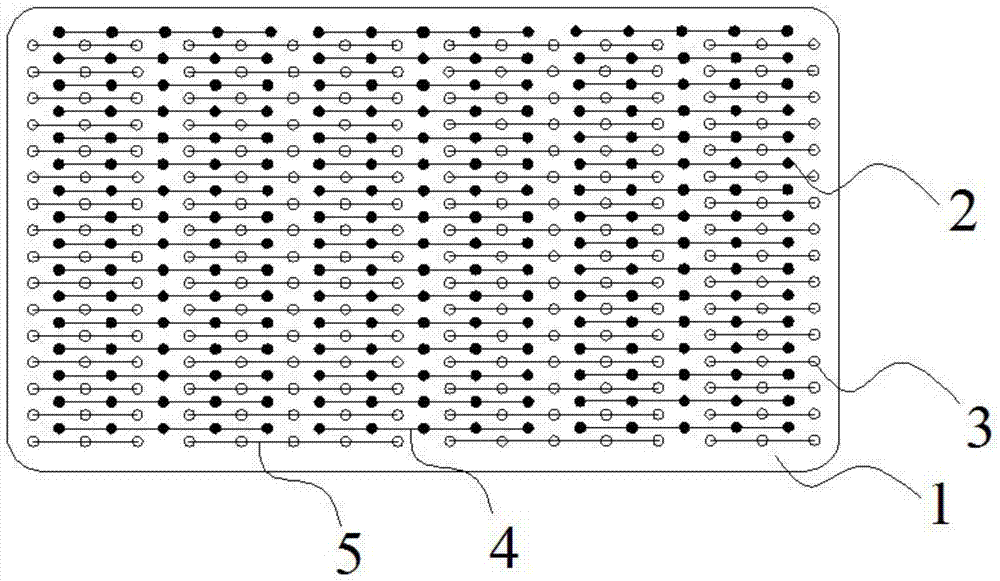

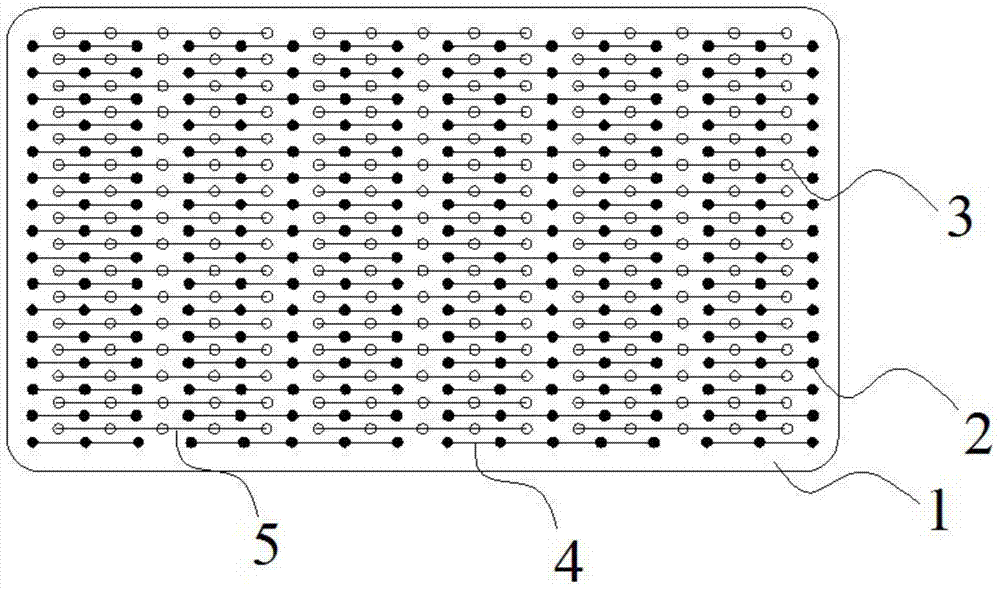

[0066] refer to figure 1 , figure 2 and Figure 4 , a busbar-free high-efficiency back-contact solar cell, the solar cell includes a solar cell sheet 1 and an electrical connection layer, the backlight surface of the solar cell sheet 1 has a P electrode connected to a P-type doped layer and an N-type doped layer The N electrode connected by heterogeneous layers is characterized in that: the electrical connection layer includes several conductive thin grid lines, and a part of the conductive thin grid lines is connected to the P electrode on the backlight surface of the solar battery sheet 1; the other part of the conductive fine grid lines The grid lines are connected to the N electrodes on the backlight surface of the solar battery sheet 1 , and the thin conductive grid lines have a multi-segment structure.

[0067] Such as Figure 4 Shown is a busbar-free high-efficiency back-contact solar battery sheet-8, in which there are 15 rows of dot-shaped P electrodes 2, 16 in ea...

Embodiment 2

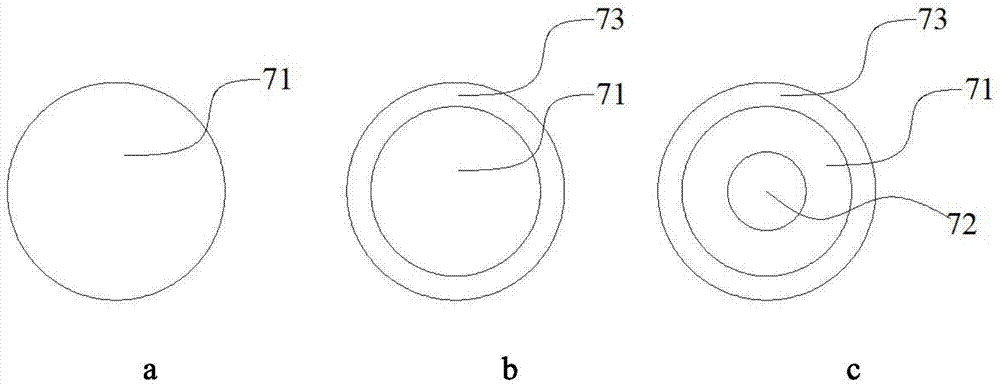

[0089] refer to Figure 5 , Figure 6 and Figure 7 , a busbar-free high-efficiency back-contact solar cell, the solar cell includes an electrical connection layer composed of more than one solar cell sheet 1, conductive wires 7 and conductive thin grid lines, and the silicon substrate backlight surface of the solar cell sheet 1 has The P electrode connected to the P-type doped layer and the N electrode connected to the N-type doped layer, the electrical connection layer on the backlight surface of the solar cell sheet 1 has several conductive thin grid lines connected to the P electrode and connected to the N electrode. A plurality of conductive thin grid lines, the conductive thin grid lines are multi-segment structures, and the intersections of the conductive thin grid lines and the conductive wires 7 are provided with barriers to prevent the electrical conduction between the conductive thin grid lines and the conductive wires 7. Insulation medium6.

[0090] like Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com