Novel direct connection method for metal wires

A technology of metal wires and new methods, applied in the direction of connection and connection through deformation, which can solve the problems of unsuitable connection of ultra-fine wires and unsuitable bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The connection objects in this embodiment are: ultra-fine metal wires with a diameter of ≤0.05 mm and thick metal wires with a diameter of about 1 mm.

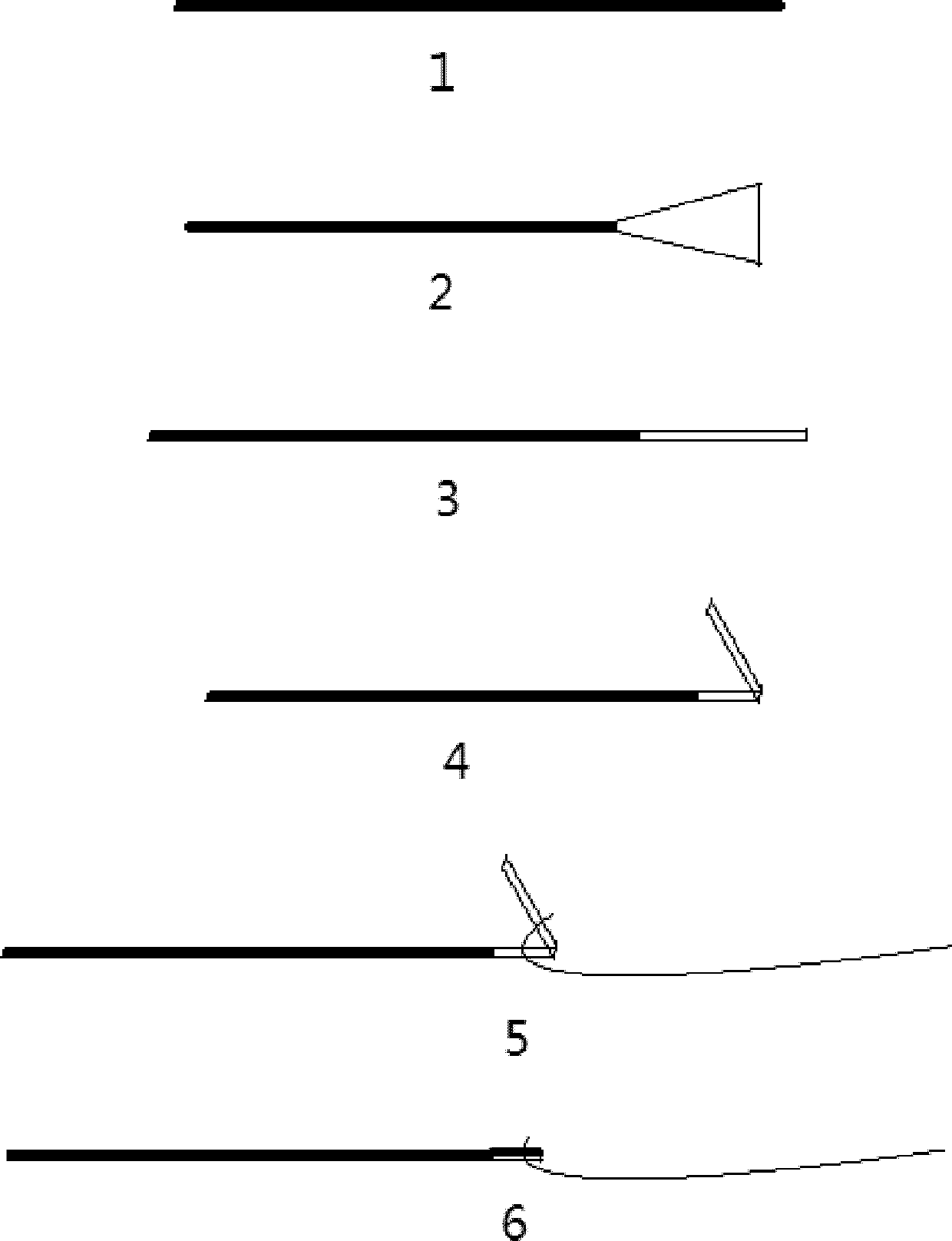

[0014] The specific connection steps of the method are as follows: figure 1 Shown:

[0015] 1. Prepare a thick metal wire with a diameter of about 1 mm;

[0016] 2. Smash one end of the above-mentioned thick metal wire into a flat sheet;

[0017] 3. Then use scissors to cut the flat sheets in step 2 into narrow strips;

[0018] 4. Then bend the narrow part in step 3 to an angle less than 90 degrees;

[0019] 5. Put one end of the ultra-fine metal wire with a diameter of ≤0.05 mm at the corner;

[0020] 6. Then press the corner tightly to complete the connection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com