Metallic corrosion velocity measurer and its measuring method adopting AC resistance probe

A metal corrosion and AC resistance technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem of small cross-sectional area of filamentous corrosion test pieces, unable to measure low corrosion rate, and difficult to ensure accuracy and other problems to achieve the effect of enhancing anti-interference ability, shortening measurement time, and avoiding the influence of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

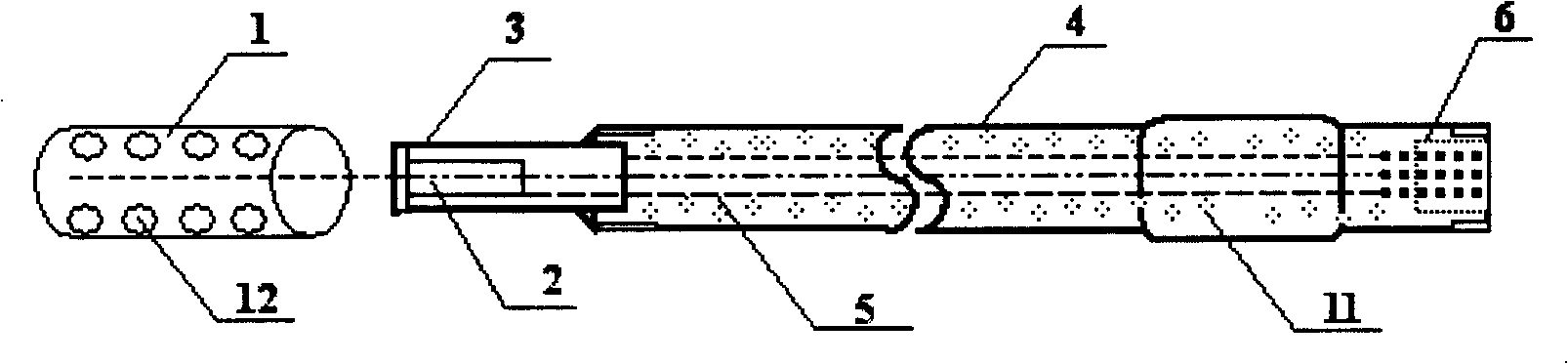

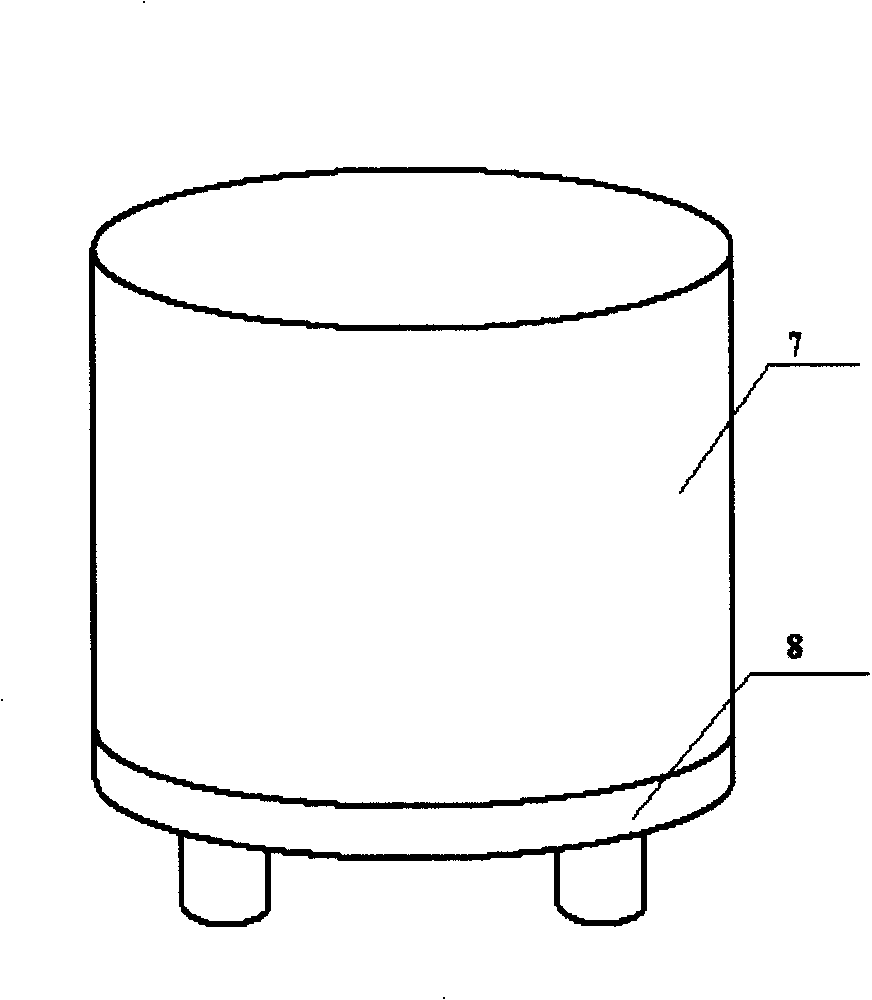

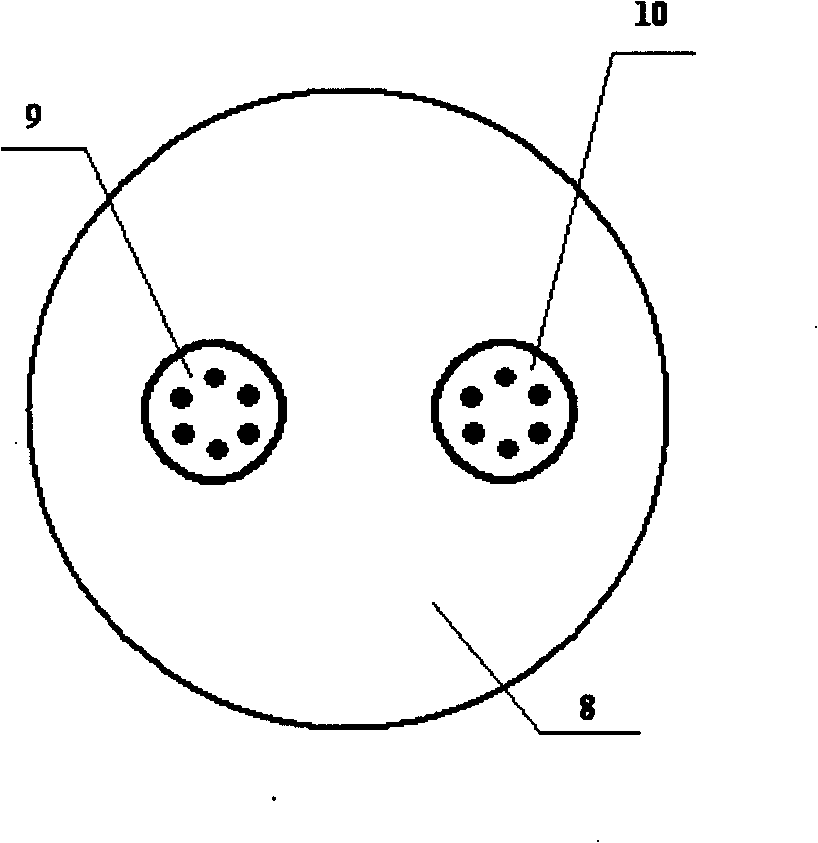

[0021] like figure 1 , Figure 2A , 2B As shown, the device of the present invention includes two parts of a resistance probe and a collector, wherein the resistance probe is composed of a corrosion test piece 3, a compensation test piece 2 and a probe rod 4. In this embodiment, the corrosion test piece 3 has a thickness of 0.5mm, A hollow tubular structure with a diameter of 8mm and an effective length of 100mm, this embodiment uses the same material as the monitoring equipment, such as carbon steel, to test the corrosion rate of the metal; the compensation test piece 2 and the corrosion test piece 3 are made of the same metal material, The unfolded plane is sheet-like (7mm×65mm), and can be placed into the hollow tube of the corrosion test piece 3 after being bent into an arc-shaped surface. The temperature compensation of the test piece; the probe rod 4 is a hollow tube, which is used to accommodate the wire 5 connecting the corrosion test piece 3 and the compensation tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com