Period-modulated flat-topped pulse device for accurately controlling output power/energy

A flat-top pulse and periodic modulation technology, which is applied in the laser field, can solve the problems of easily damaged devices, dust pollution lasers, and inaccurate control of output power/energy accuracy, achieving high precision and strong tunability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

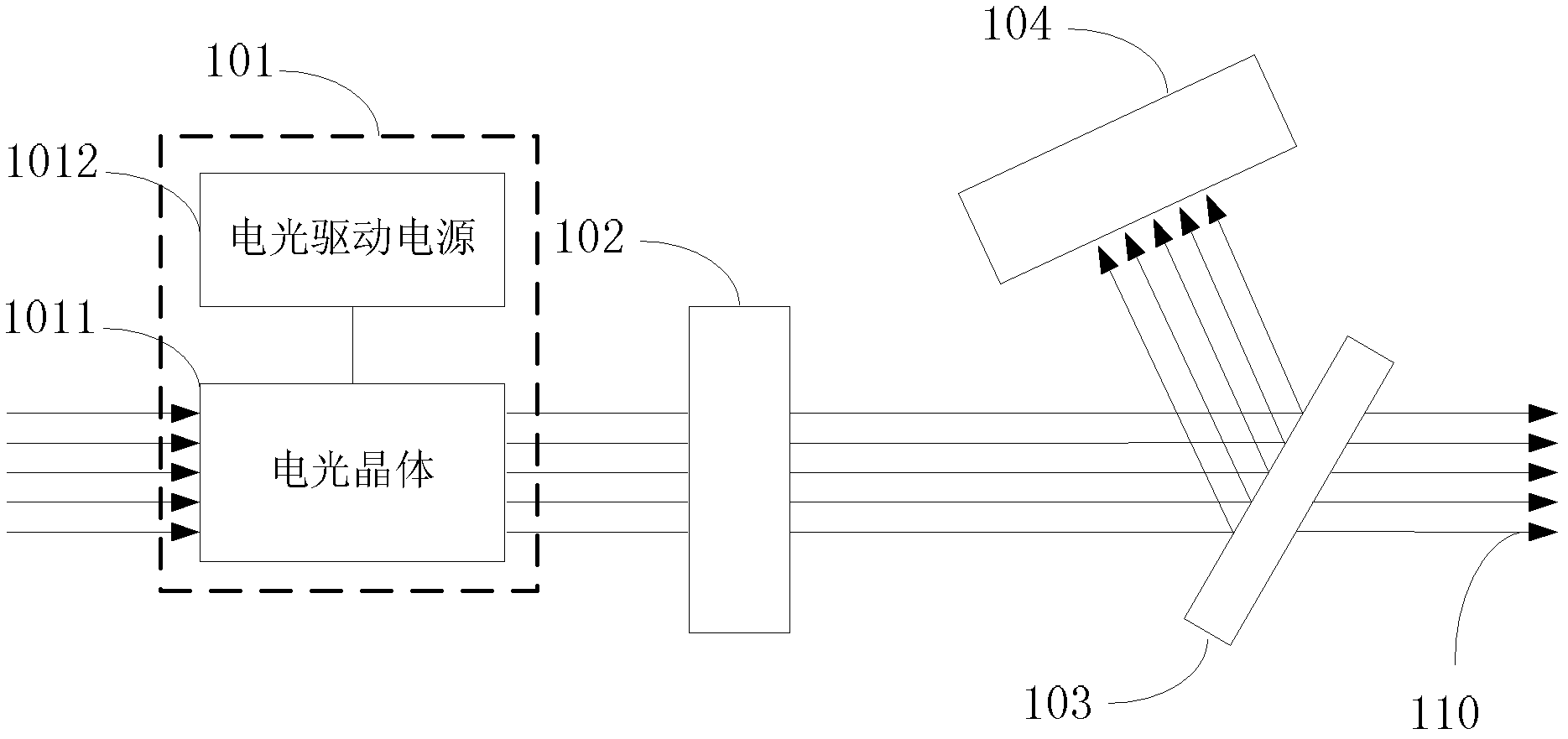

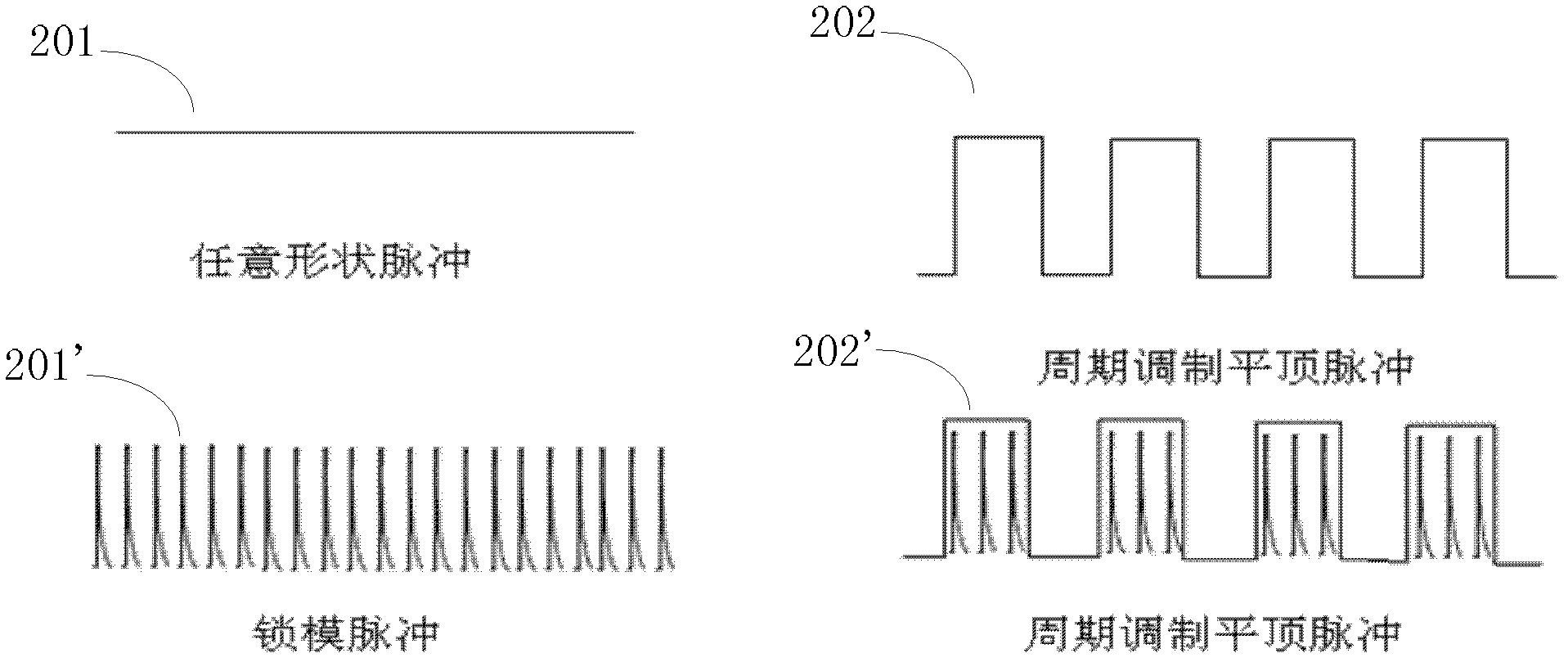

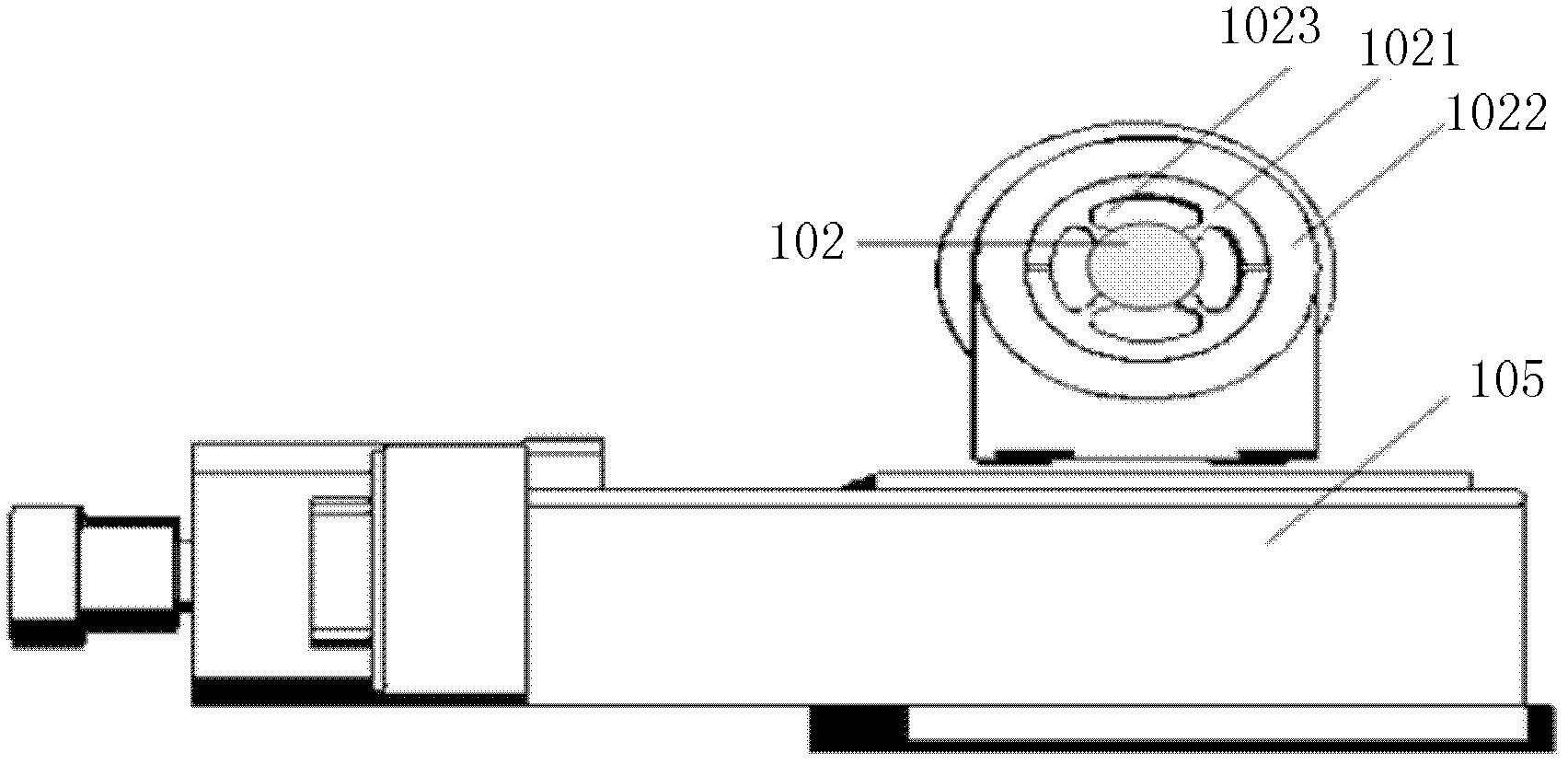

[0025] An embodiment of the present invention provides a device for realizing periodic modulation of flat-top pulses. Such as figure 1 As shown, the device sequentially includes an electro-optic switch 101 , a 1 / 2 wave plate 102 , a polarizing device 103 and a waste light collection device 104 along the optical path. Among them, the electro-optic switch 101 mainly completes the function of periodically modulating the flat-top pulse, and the output waveform of the periodically modulated flat-top pulse has a rising edge and a falling edge of less than 3 ns. The 1 / 2 wave plate 102 is used to convert horizontally po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com