Breaker discharging opening gap adjusting mechanism and jaw type breaker

A technology of gap adjustment and discharge port, which is applied in grain processing and other directions, can solve the problem of large space occupation, and achieve the effect of compact structure and improved convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

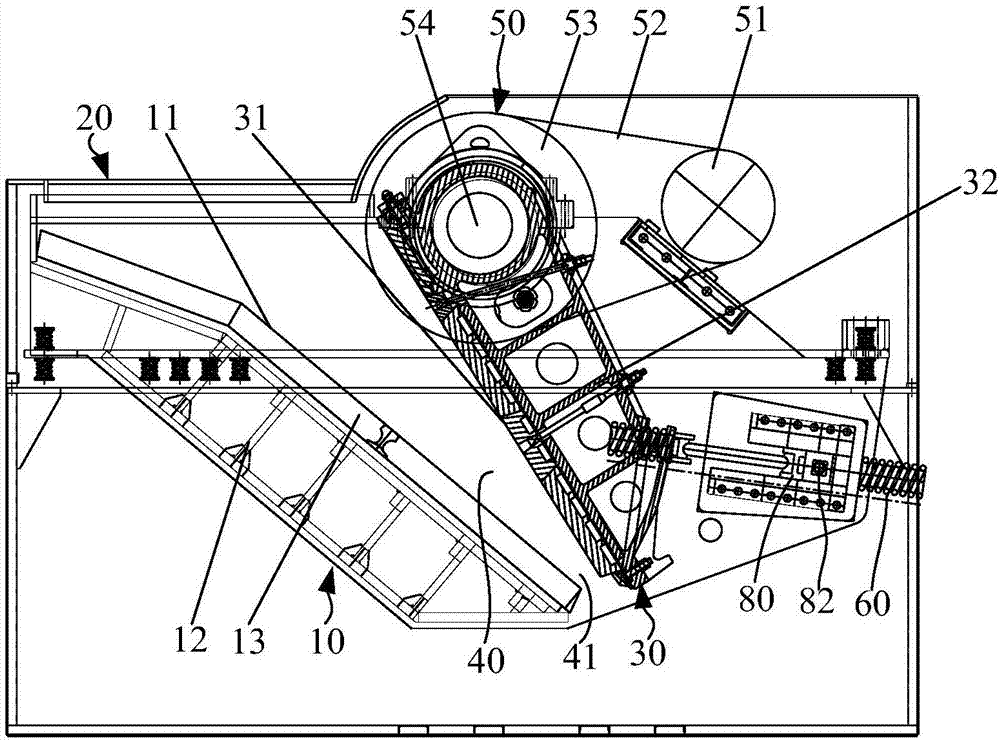

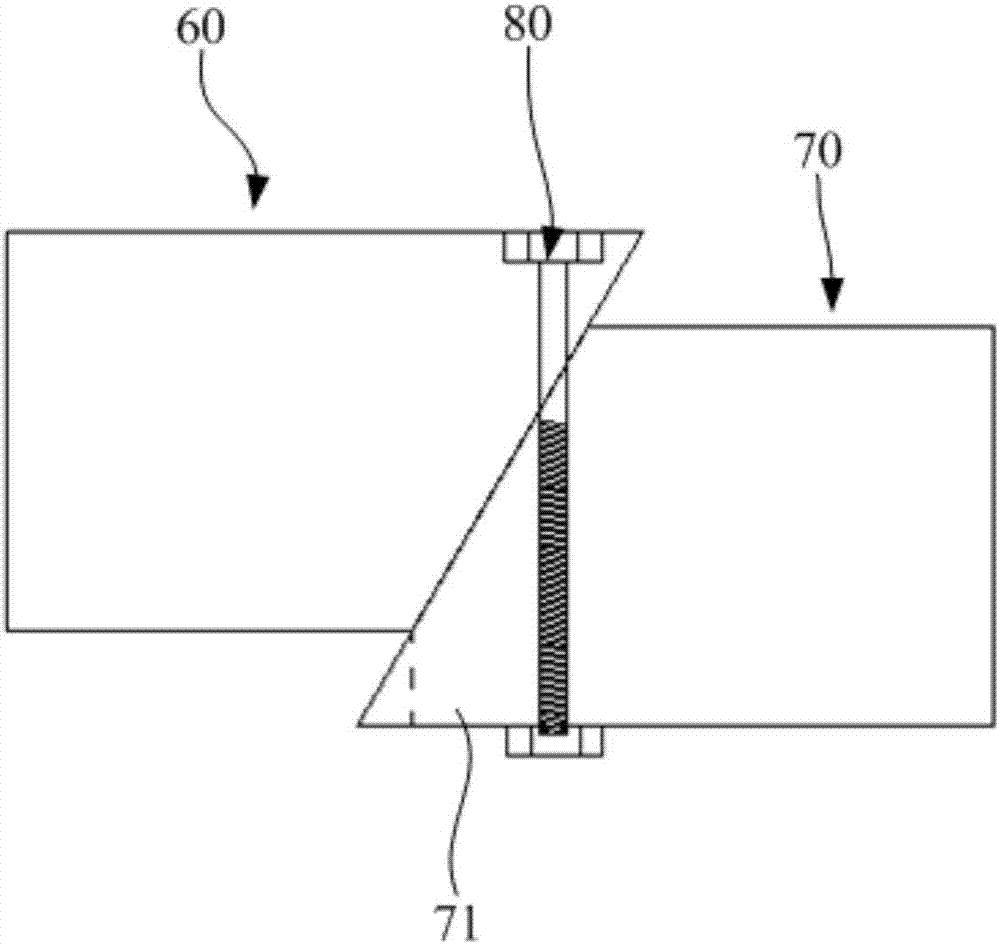

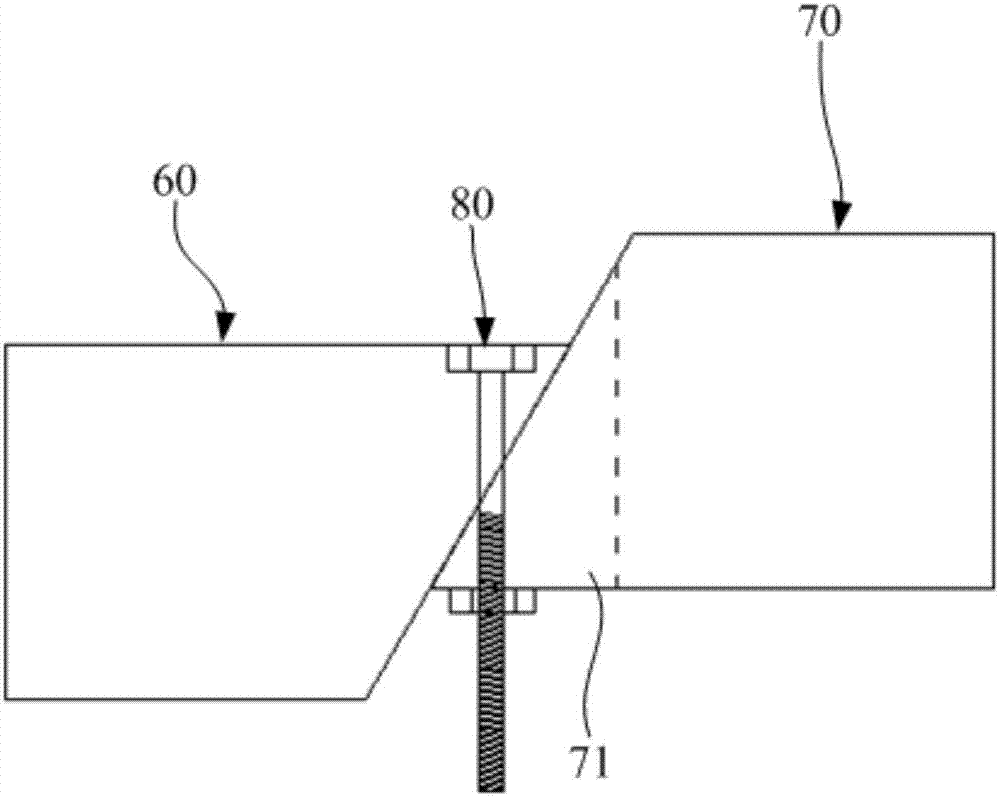

[0032] Such as Figure 1 to Figure 4As shown, according to this embodiment, the gap adjustment mechanism at the discharge port of the crusher is arranged between the movable jaw assembly 30 and the frame 20, and by adjusting the distance between the movable jaw assembly 30 and the frame 20, the movable jaw assembly 30 and the frame 20 are realized. Adjustment of the gap between the discharge ports 41 between the static jaw assemblies 10. The discharge opening gap adjustment mechanism in this embodiment includes a first wedge block 60 and a second wedge block 70 as a wedge mechanism, and an adjustment screw 81 and an adjustment nut 82 as an adjustment device 80 . The angle between the normal line of the wedge surface in the first wedge 60 and the second wedge 70 and the adjustment direction is smaller than the self-locking angle of the wedge, and the adjustment screw 81 and the adjustment nut 82 drive the first wedge 60 and the second The part where the wedge-shaped surface in...

Embodiment 2

[0040] The difference between the gap adjustment mechanism at the discharge port of the crusher in this embodiment and Embodiment 1 is that the adjustment mechanism is arranged between the static jaw assembly 10 and the frame, and its specific structure can be found in Embodiment 1, so it will not be repeated here. It can also be realized that the adjustment device in the gap adjustment mechanism does not need to occupy space in the adjustment direction of the gap adjustment mechanism, for example, does not need to occupy space at both ends of the wedge mechanism, thus ensuring the compact structure of the entire adjustment mechanism.

[0041] It can be understood that the adjustment mechanism is arranged between the static jaw assembly 10 and the frame, and is also arranged between the movable jaw assembly and the frame, which can also achieve the purpose of the present invention.

Embodiment 3

[0043] The difference between the gap adjustment mechanism at the discharge port of the crusher in this embodiment and Embodiment 1 is that the adjustment device is a hydraulic telescopic cylinder 90 arranged in the accommodation cavity in the first wedge block and the second wedge block, and the hydraulic telescopic cylinder 90 The two ends of the two sides are respectively connected to the first wedge block and the second wedge block, so that when the first wedge block and the second wedge block are driven to realize the adjustment of the outlet gap, the hydraulic telescopic cylinder 90 can be combined with the hydraulic device, Realize the automation of the gap adjustment of the gap adjustment mechanism of the discharge port of the crusher.

[0044] see further Figure 5 and Figure 6 , in this embodiment, the gap adjustment mechanism at the discharge port of the crusher also includes a limit mechanism arranged on the first wedge block 60 and the second wedge block 70, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com