Transmission between an engine input shaft and an output shaft of a motor vehicle

A technology for output shafts and transmissions, applied in the direction of mechanical drive clutches, agricultural machinery and implements, mechanical equipment, etc., can solve the problems of lack of reliability, complicated second clutch control device, etc., and achieve the effect of completely reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

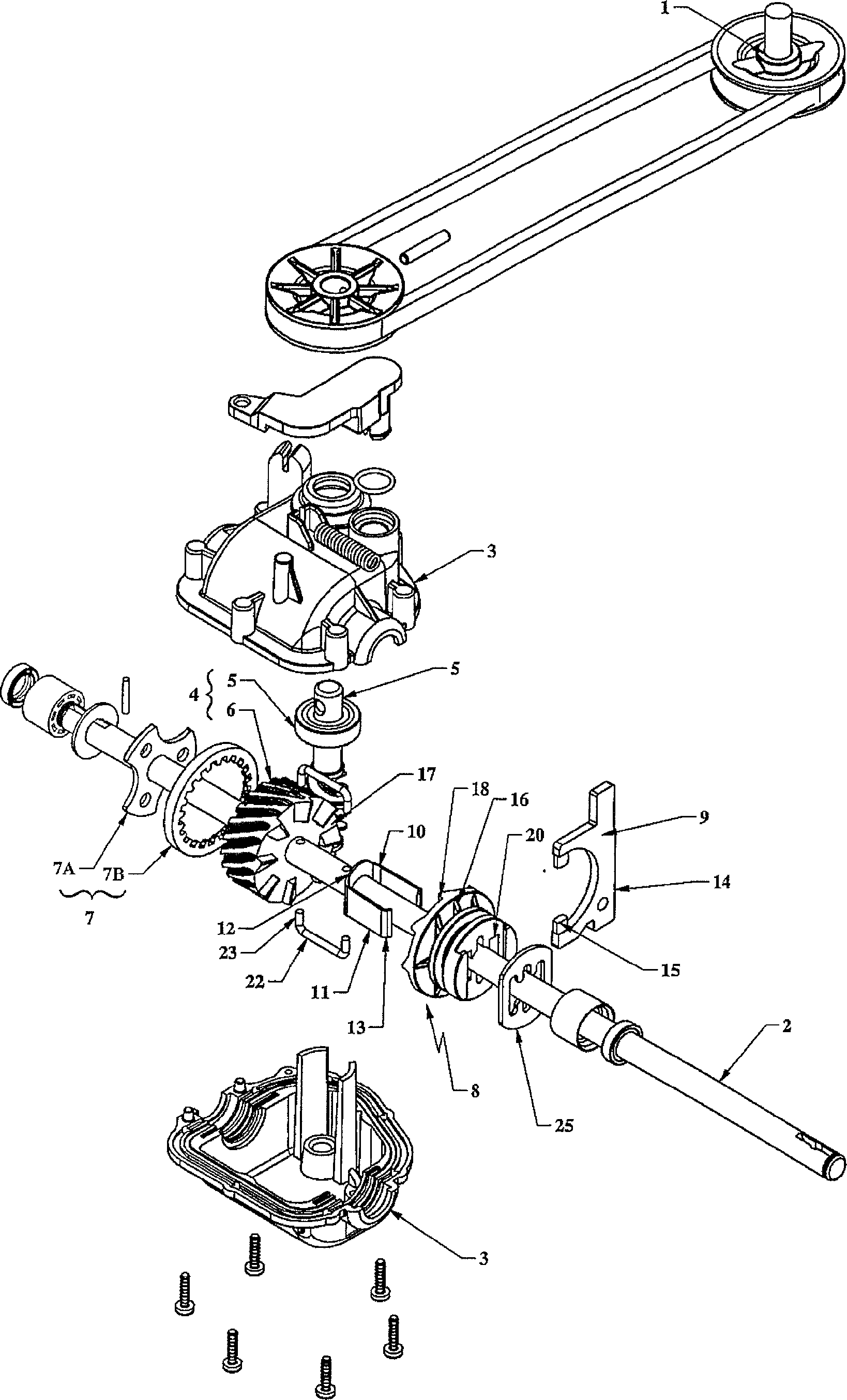

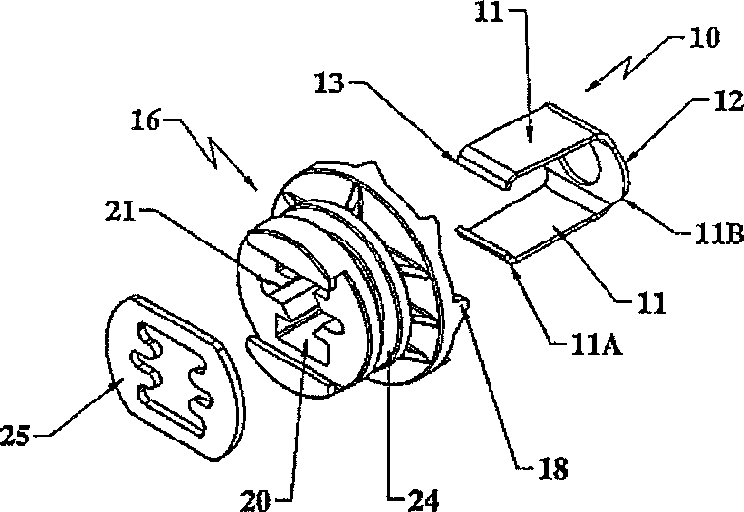

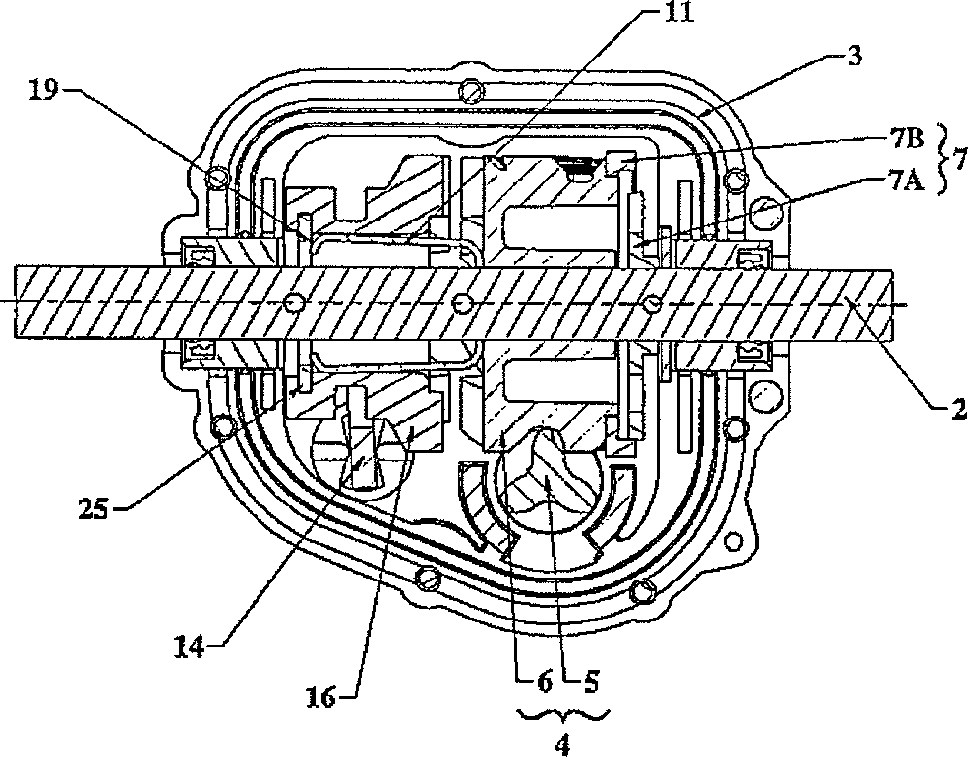

[0023] As described above, the transmission of the present invention is used to transmit rotational motion from a drive shaft 1 of a self-propelled machine, such as a lawnmower, to an output shaft 2, such as a shaft for driving the wheels of the machine, and comprises at least one A housing 3 , which is usually made of synthetic material, comprises, for example, two half-shells, which are assembled together via a joint surface. The housing 3 at least partially houses: a reduction mechanism 4; two clutch mechanisms 7 and 8; and a clutch control device. as in figure 1shown in the reduction mechanism 4 comprises a drive member 5, formed, for example, by a worm, which engages with a driven rotating member 6, which in the example shown is free to rotate by being mounted on the output shaft 2 And free axially moving gears are formed. The driven rotating member 6 or gear is adapted to be engaged / disengaged from the output shaft 2 by means of two clutch mechanisms 7 and 8 , each of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com