Workpiece material and grasping mechanism

A technology for processing materials and holding parts, applied in metal processing, metal processing equipment, mechanical equipment, etc., can solve the problems of reduced tool and device life, increased processing tool load, and increased chip processing burden, etc. The effect of shortening the time and reducing the material removal part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] First, the processed material of the present invention, that is, the processed material 100 of the first embodiment will be described.

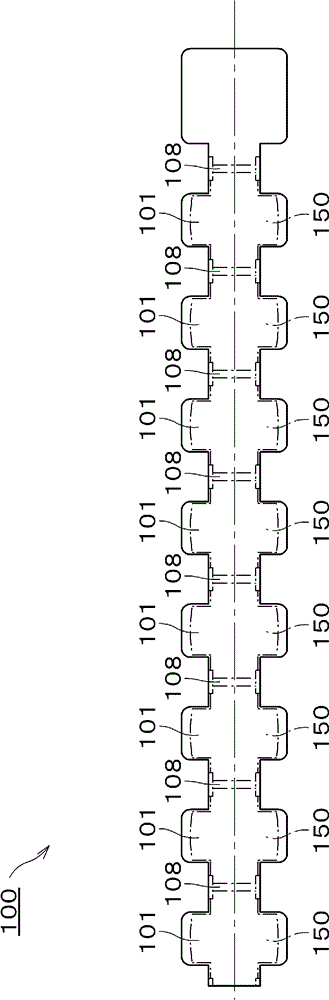

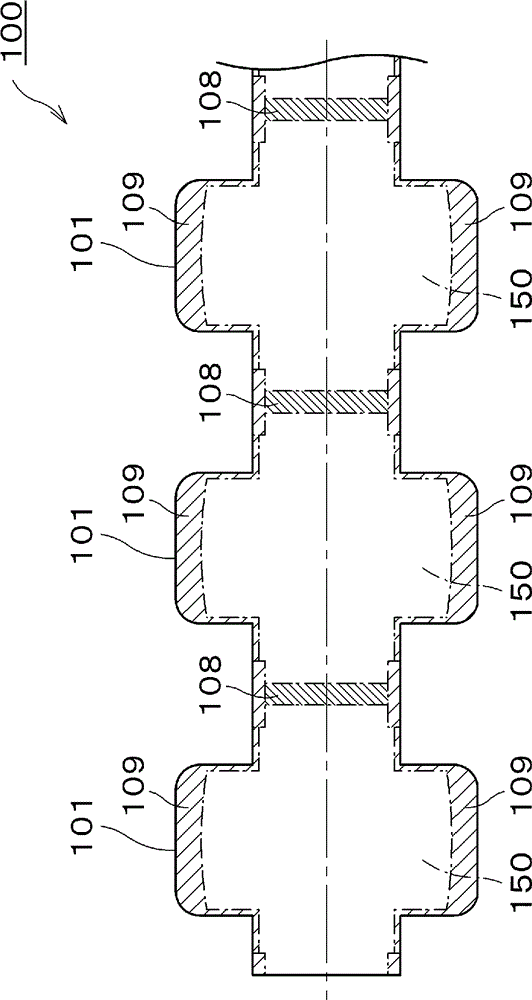

[0067] Such as figure 1 , figure 2 As shown, the processed material 100 is configured such that a plurality of rough materials 101 are arranged in a row with a margin for cutting 108 provided therebetween, and are formed integrally from a single material.

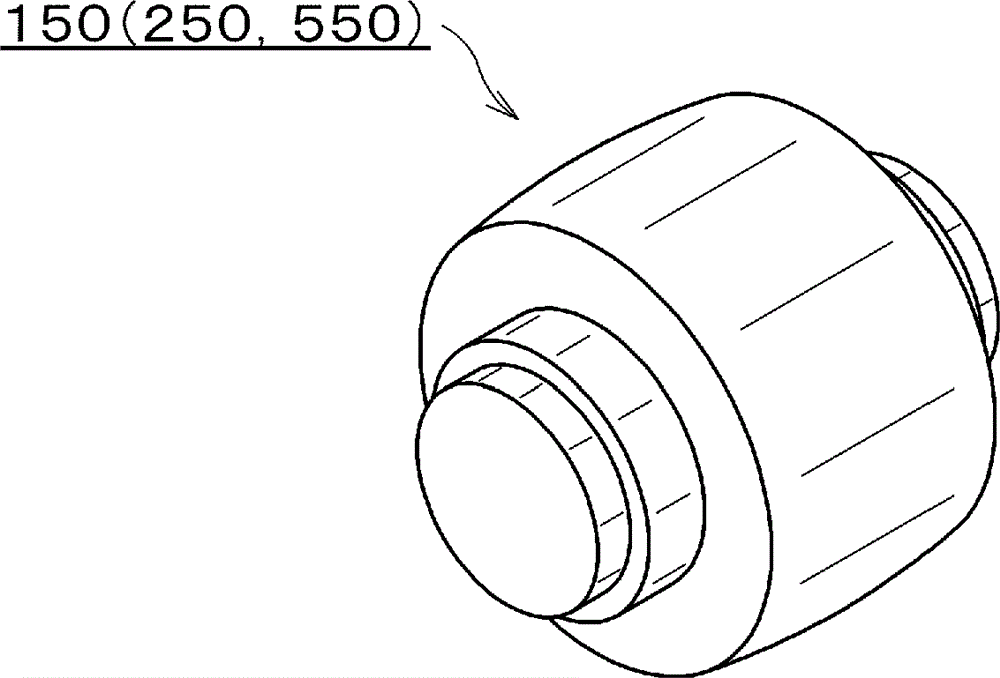

[0068] Each rough material 101 has a required material removal portion 109 on the outer periphery in such a manner that it is formed into one product by material removal processing such as cutting, and presents a shape similar to that of image 3 The product 150 shown is externally similar in shape. In addition, the product may be a semi-finished product that requires secondary processing or the like in addition to a finished product that has been completely processed.

[0069] If the material is a metal material, the processed material 100 may be a material formed integrally by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com