Tire comprising casing reinforcement cables having a low perviousness, and variable rubber mixture thicknesses

A technology of rubber compound and tire crown reinforcement, which is applied to the reinforcement layer of pneumatic tires, heavy-duty tires, pneumatic tires, etc., can solve the problem of high tire cost and achieve the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

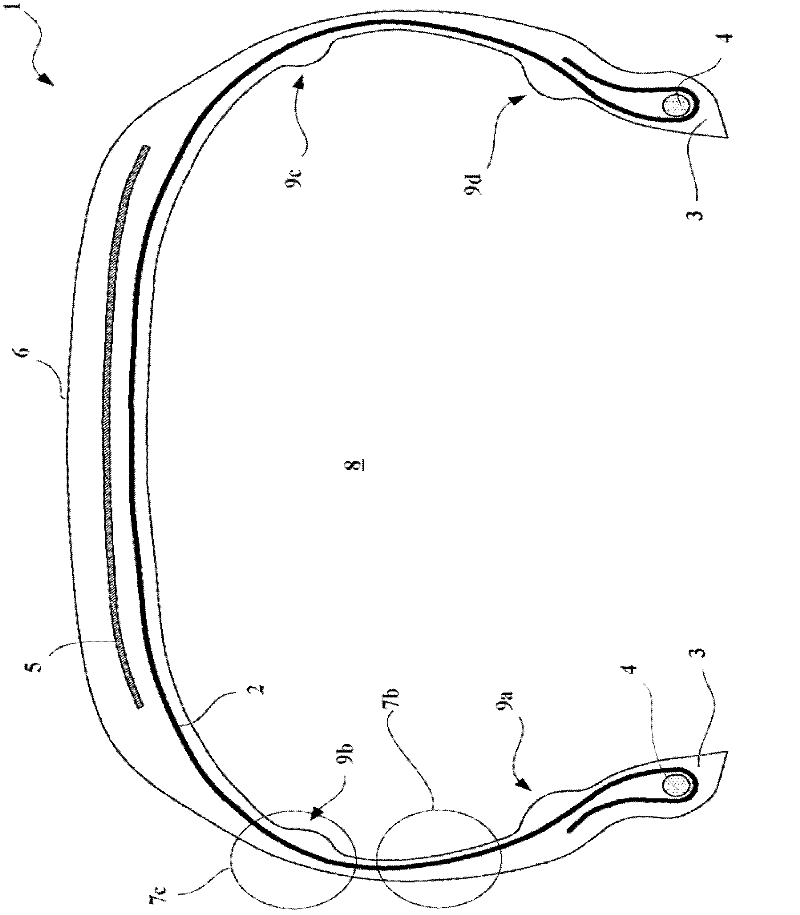

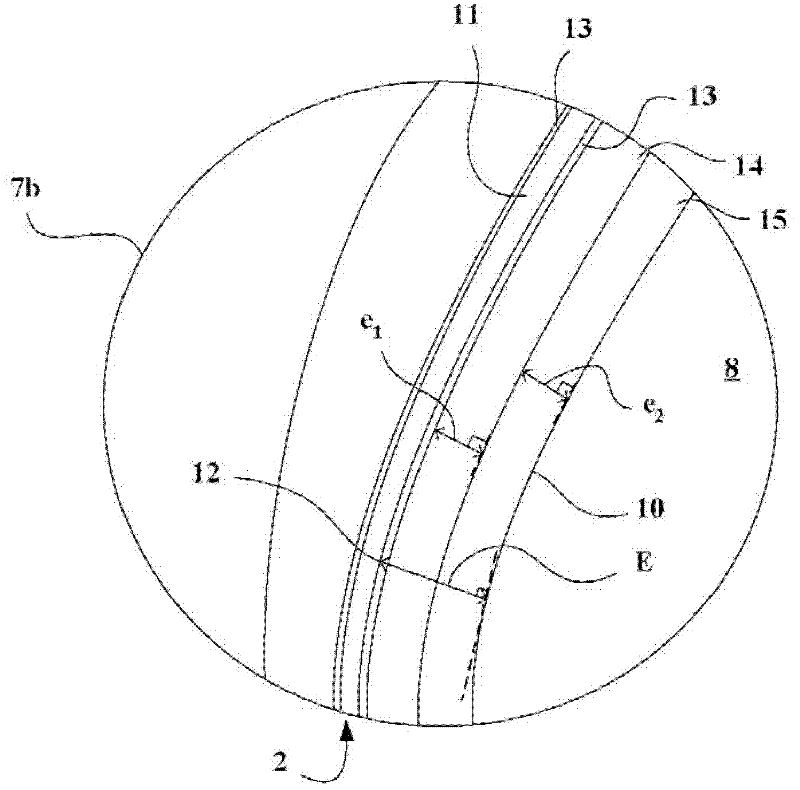

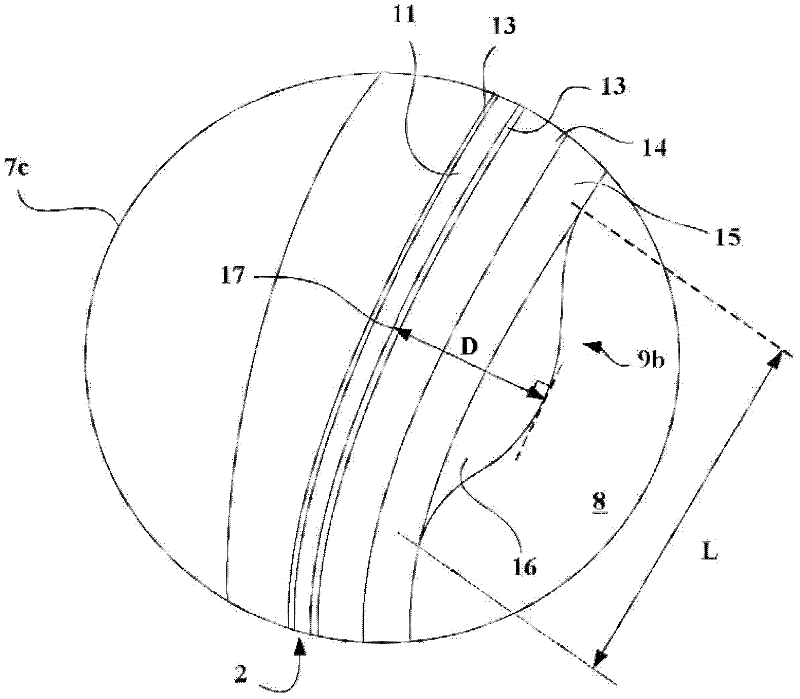

[0132] exist Figure 1a Among them, a tire 1 of type 315 / 70R 22.5 comprises a radial carcass reinforcement 2 anchored in two beads 3 around a bead wire 4 . The carcass reinforcement 2 is formed of a single layer of metal cords 11 and two calendered layers 13 . The carcass reinforcement 2 is hooped with a crown reinforcement 5 itself covered with a tread 6 . The crown reinforcement 5 is formed radially from the inside to the outside by:

[0133] - a first working layer formed of continuous non-hooped non-extensible metal cords 11.35 over the entire width of the ply, said cords being oriented at an angle of 18°;

[0134] - a second working layer formed over the entire width of the ply by continuous non-hooped inextensible metal cords 11.35 oriented at an angle of 18° and crossing the metal cords of the first working layer; and

[0135]- A protective layer formed of elastic metal cords 6×35.

[0136] All the layers making up the crown reinforcement 5 are not specifically show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com