Permanent magnet rotor assembly provided with welded magnet retaining elements

A technology of permanent magnets and rotors, applied in the direction of electrical components, electric components, magnetic circuit rotating parts, etc., can solve the problems of increasing the manufacturing cost of the rotor, high cost, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

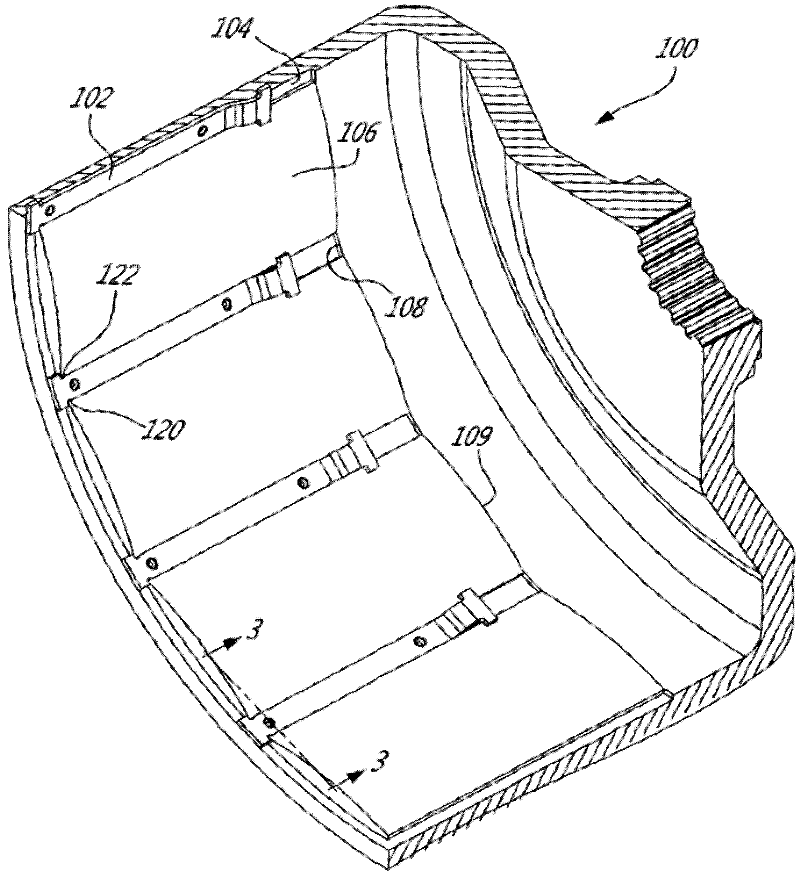

[0060] According to the illustrated embodiment, there is provided a rotor assembly for an external rotor electric machine, the rotor assembly comprising:

[0061] a generally cylindrical rotor body having an interior surface; the generally cylindrical rotor body defining a longitudinal axis of rotation;

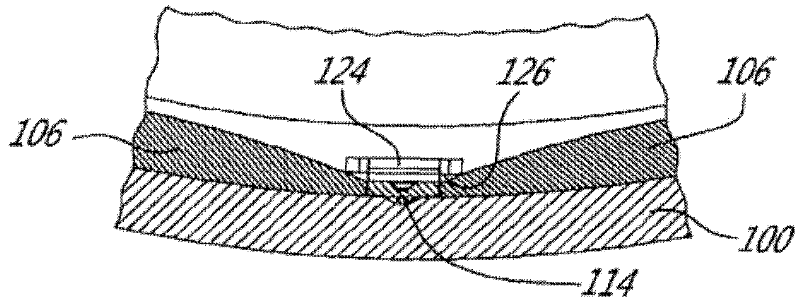

[0062] at least two permanent magnets mounted longitudinally to the interior surface of the rotor body, each at least two permanent magnets comprising longitudinally opposed first and second ends and opposed first and second faces a face, the first face configured and sized to contact the interior surface of the rotor body;

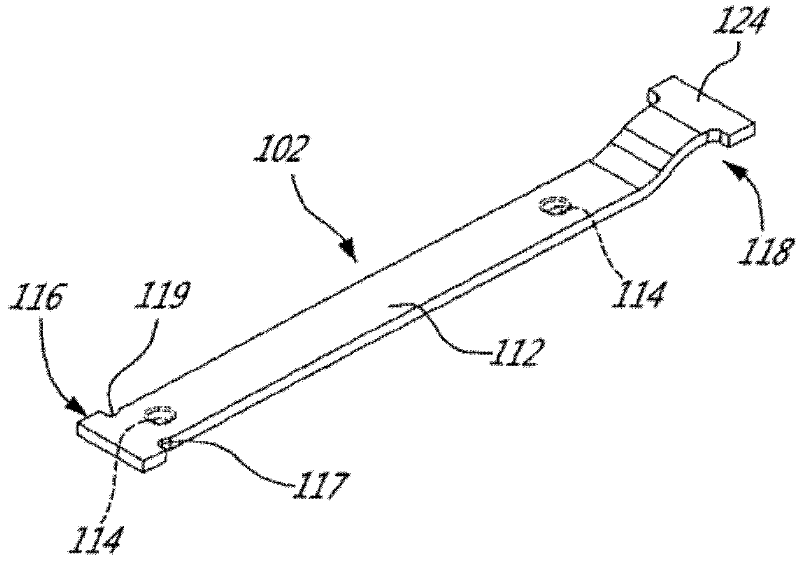

[0063] at least two spacer elements mounted longitudinally to the inner surface of the rotor body and between adjacent permanent magnets via at least one respective weld; the at least two spacer elements are Constructed and sized to resist relative circumferential and radial movement of the permanent magnets relative to the rotor body.

[0064] When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com