Self-protection safety working head of lawn mower

A self-protection and lawn machine technology, which is applied in the direction of lawn mowers, harvesters, agricultural machinery and implements, etc., can solve the problems of working head and blade damage, blade fragmentation, working head cannot move, etc., to improve the ability to cross obstacles capacity, machine reliability, and the effect of improving structural reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

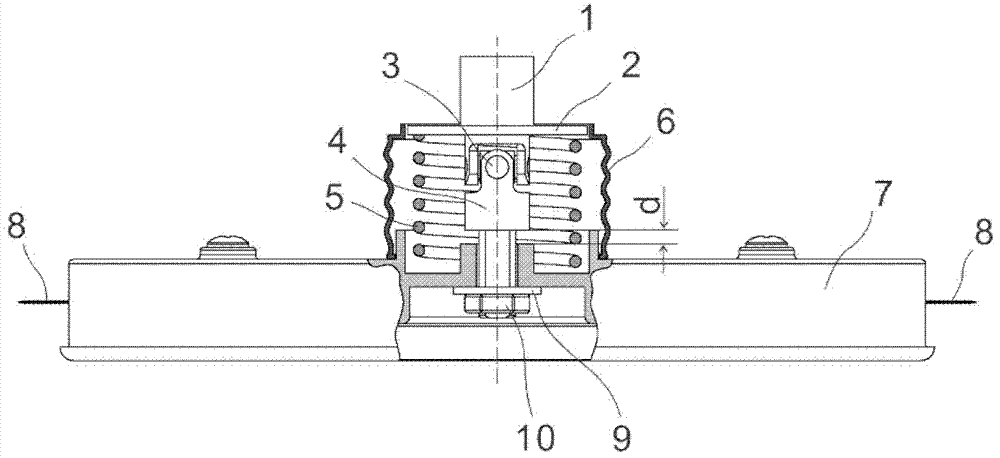

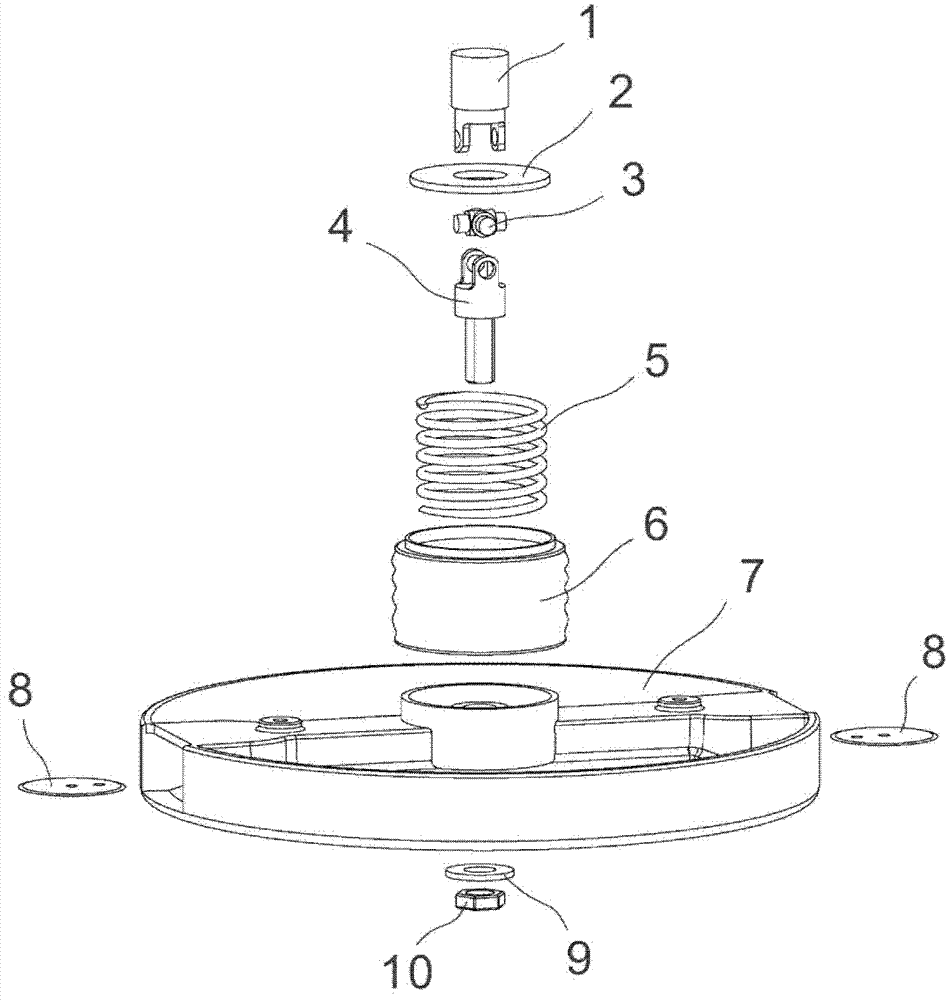

[0029] like figure 1 , figure 2 As shown in the figure, a self-protecting safety working head of a lawn mower of the present invention, a circular cutter head 7 is equipped with a blade 8, and the circular cutter head 7 is installed on a connecting rod 4 through a nut 10 and a washer 9, and the connecting rod 4 passes through the ten thousand The joint 3 is connected with the motor output shaft 1, the circular cutter head 7 and the connecting rod 4 are clearance fit, there is an axial movable distance d between the circular cutter head 7 and the connecting rod 4, and the circular cutter head 7 and the motor output A spring 5 is arranged between the shafts 1, a spring retaining ring 2 is installed above the spring 5 on the motor output shaft 1, and a rubber protective cover 6 is arranged on the outside of the spring 5.

Embodiment 2

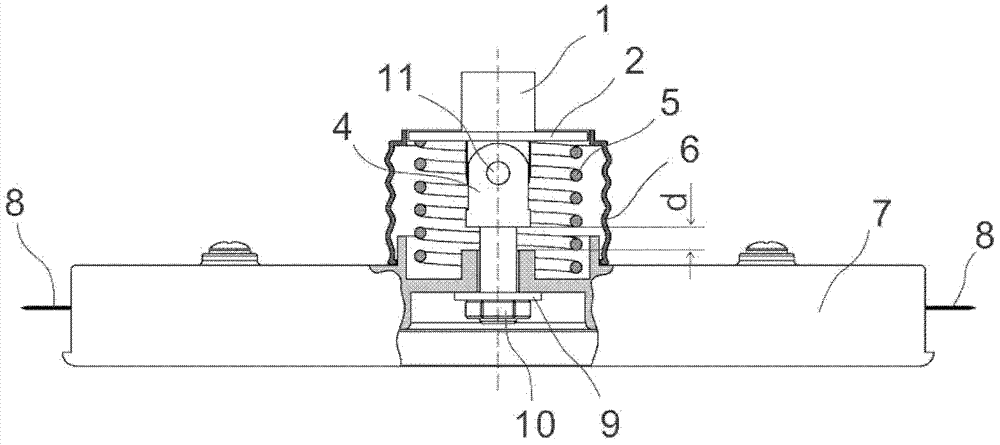

[0031] like image 3 , Figure 4 As shown, a self-protecting safety working head of a lawn mower of the present invention has a circular cutter head 7 equipped with a blade 8, and the circular cutter head 7 is installed on the connecting rod 4 through a nut 10 and a washer 9, and the connecting rod 4 is locked. The pin 11 is hinged with the motor output shaft 1, the circular cutter head 7 and the connecting rod 4 are clearance fit, there is an axial movable distance d between the circular cutter head 7 and the connecting rod 4, and the circular cutter head 7 and the motor output shaft A spring 5 is arranged in the space 1. A spring retaining ring 2 is installed on the motor output shaft 1 above the spring 5. A rubber protective cover 6 is arranged on the outside of the spring 5.

Embodiment 3

[0033] like Figure 5 , Image 6 As shown, the present invention is a self-protection safety working head of a lawn mower. The circular cutter head 7 is equipped with a blade 8. The circular cutter head 7 is installed on the motor output shaft 1 through a nut 10 and a washer 9. The circular cutter head 7 There is a clearance fit with the motor output shaft 1, there is a movable distance d in the axial direction between the circular cutter head 7 and the motor output shaft 1, a spring 5 is arranged between the circular cutter head 7 and the motor output shaft 1, and there is a spring stop above the spring 5 The ring 2 is installed on the motor output shaft 1, and the outer surface of the spring 5 is provided with a rubber protective cover 6.

[0034] According to the above three embodiments, under the action of the spring 5, the circular cutter head 7 can move the movable distance d in the axial direction, and can swing around the universal joint 3 or the lock pin 11, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com