Alcoholic extract paste of common coltsfoot flower and preparation method and application thereof

A technology of coltsfoot flower and extract, which is applied in the field of tobacco additive preparation to achieve the effect of enriching the aroma of cigarettes, improving the aftertaste and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

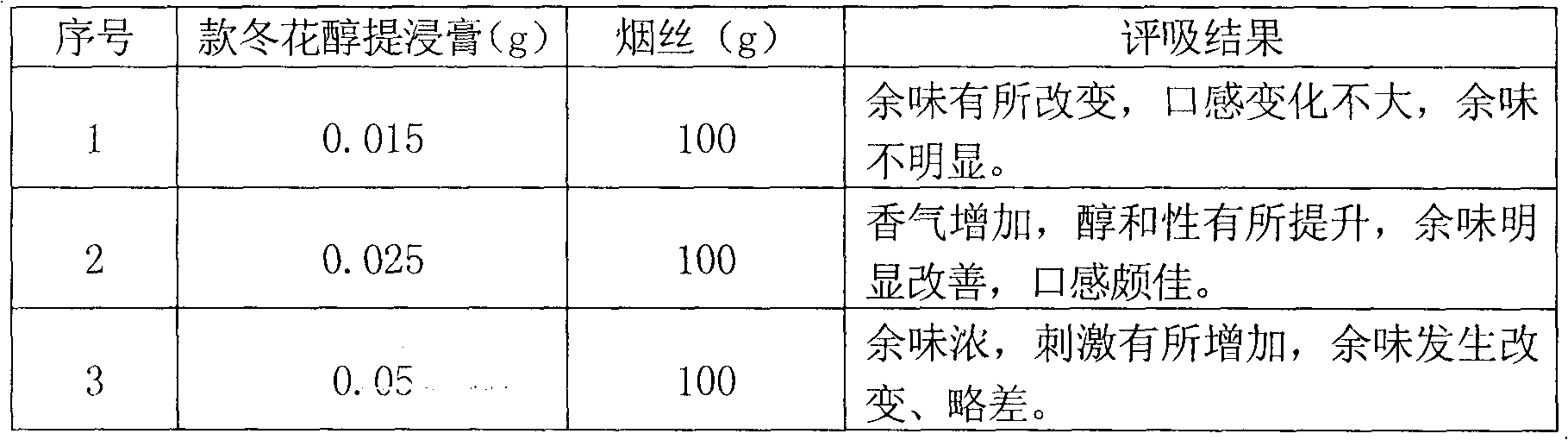

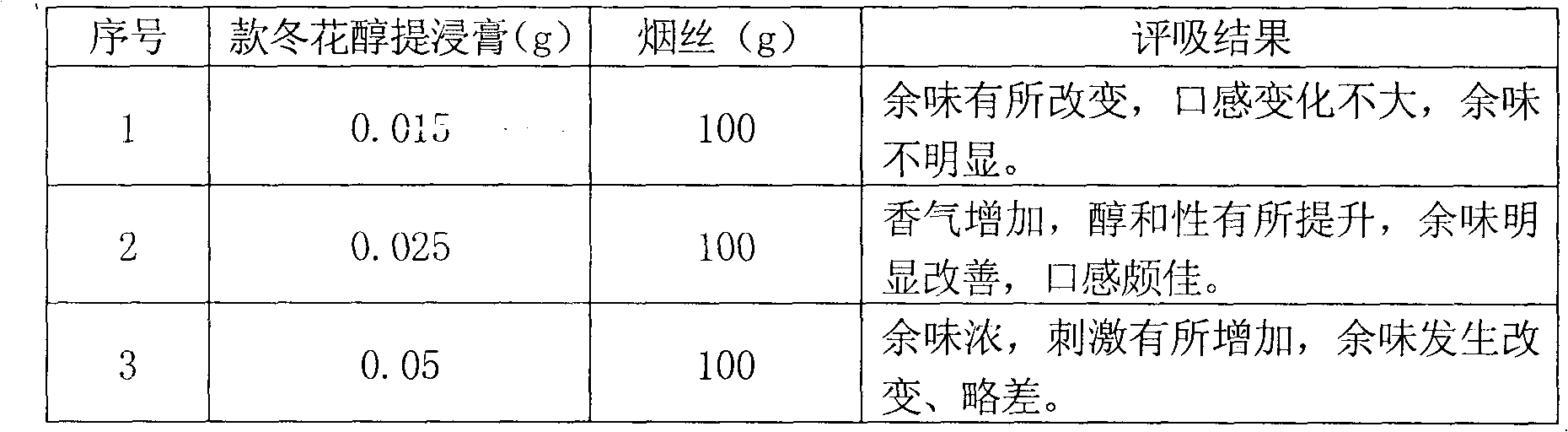

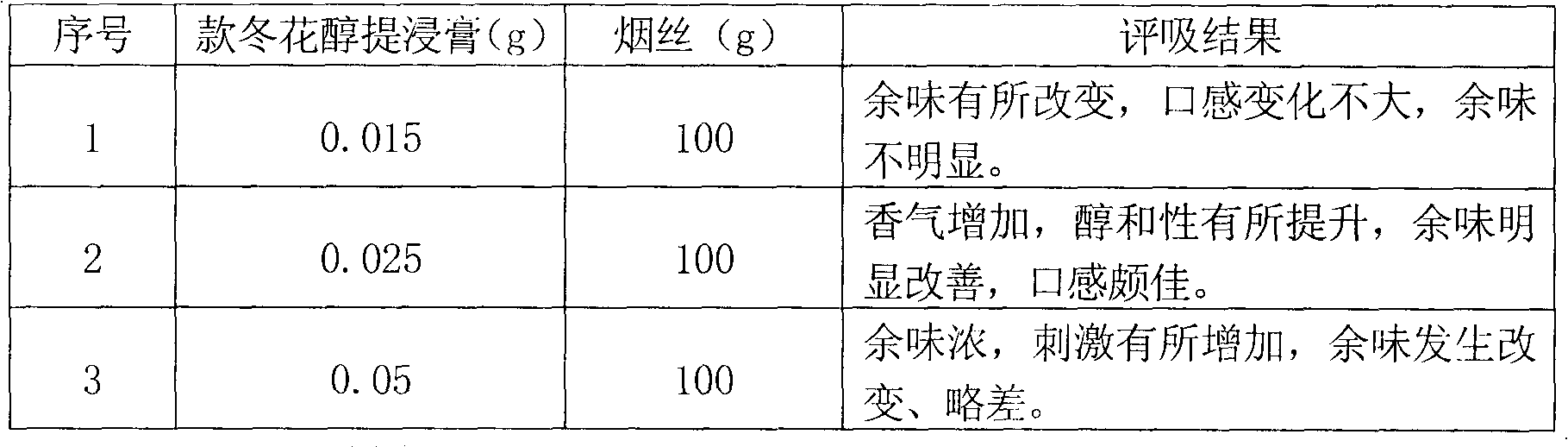

Examples

Embodiment 1

[0030] Take by weighing 1000 grams of coltsfoot coarse powder that has been crushed through a 20-mesh sieve, put it into an Erlenmeyer flask, add 5000 ml of ethanol with a concentration of 95%, uniformly stir, heat and soak for 48 hours at 30 ° C, carry out solid-liquid separation with a Buchner funnel, and collect To clarify the liquid, the obtained liquid was first distilled at 60°C under normal pressure for 0.5h, then concentrated by distillation at a vacuum of 0.025Mpa and a distillation temperature of 30°C for 1.5h to obtain 15.3 grams of extract.

Embodiment 2

[0032] Take by weighing 1000 grams of coltsfoot coarse powder that has been crushed through a 30-mesh sieve, put it into an Erlenmeyer flask, add 7500 ml of ethanol with a concentration of 75%, uniformly stir, heat and soak for 24 hours at 50°C, carry out solid-liquid separation with a Buchner funnel, and collect To clarify the liquid, the obtained liquid was first distilled at 60°C under normal pressure for 0.5h, then concentrated by distillation at a vacuum of 0.05Mpa and a distillation temperature of 50°C for 1h to obtain 15.0 g of extract.

Embodiment 3

[0034] Take by weighing 1000 grams of coltsfoot coarse powder that has been crushed through a 20 mesh sieve, put it into an Erlenmeyer flask, add 10,000 ml of ethanol with a concentration of 55%, stir and soak evenly at 20°C for 72 hours, carry out solid-liquid separation with a Buchner funnel, and collect To clarify the liquid, the obtained liquid was first distilled at 60°C under normal pressure for 0.5h, then concentrated by distillation at a vacuum of 0.01Mpa and a distillation temperature of 15°C for 3h to obtain 14.8 grams of extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com