Soybean milk machine with split style cup body structure

A technology of cup structure and soybean milk machine, which is applied in the field of electrical appliances, can solve problems such as inconvenient use, and achieve the effects of reducing costs and improving adaptability and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

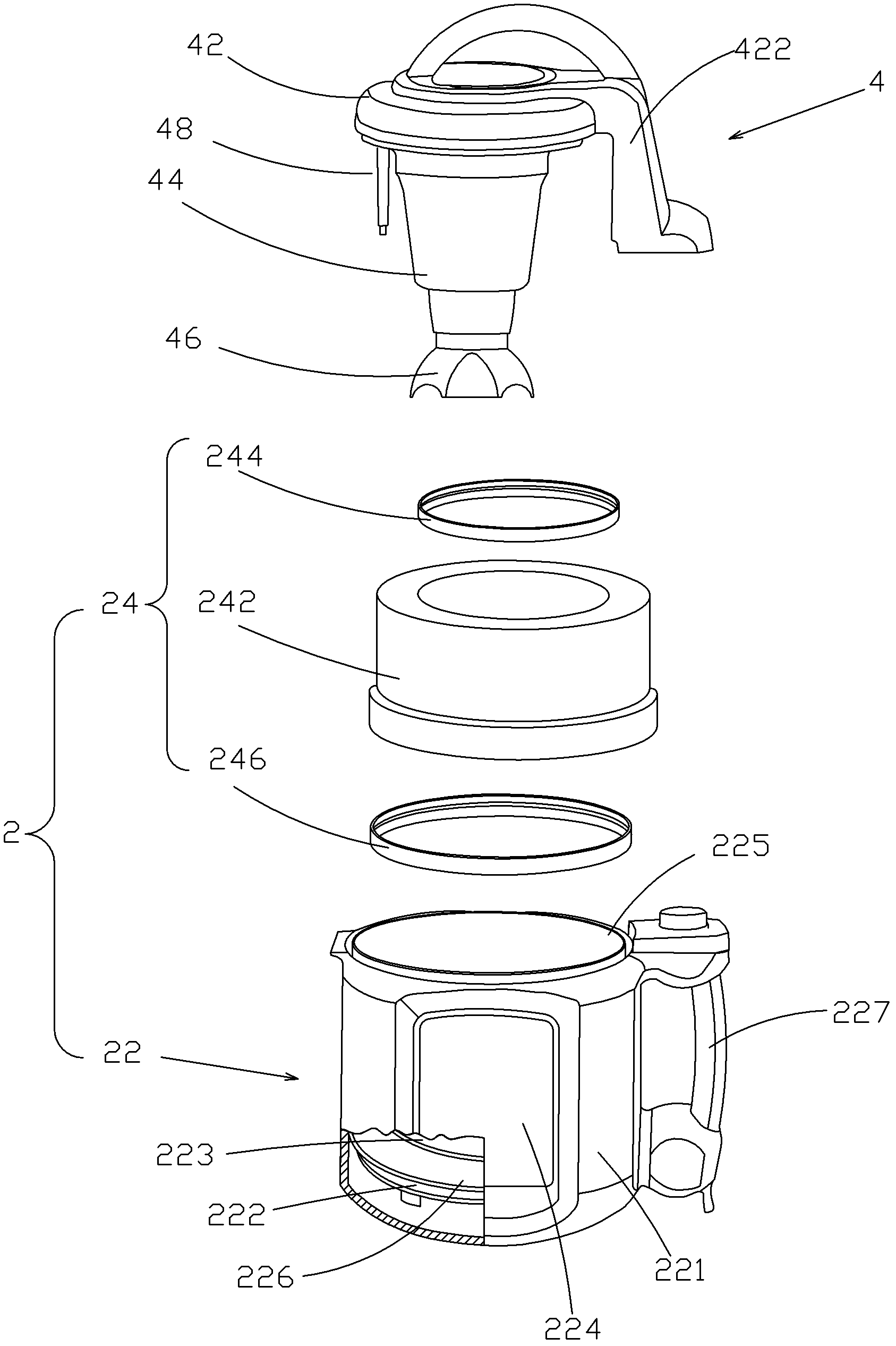

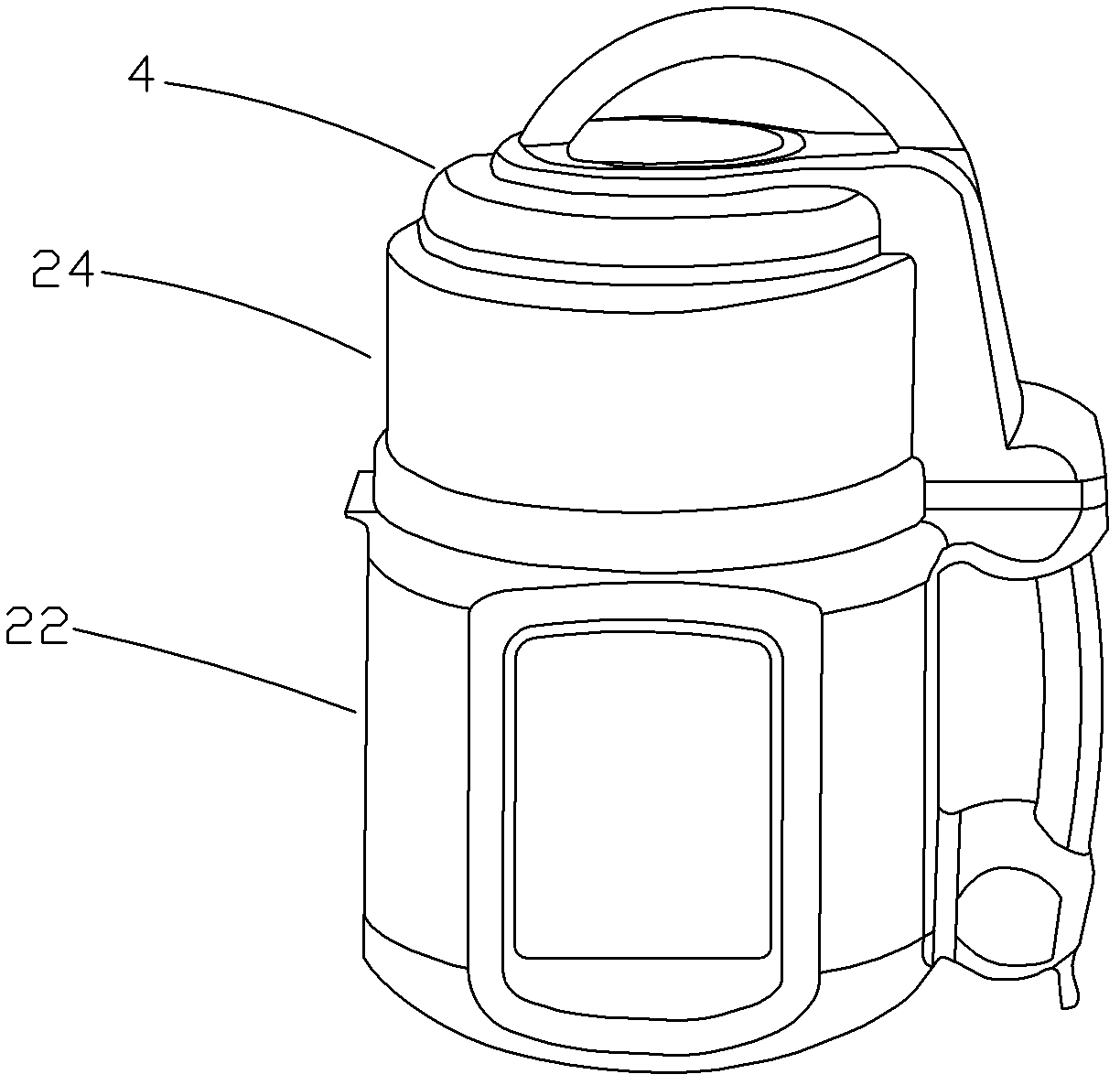

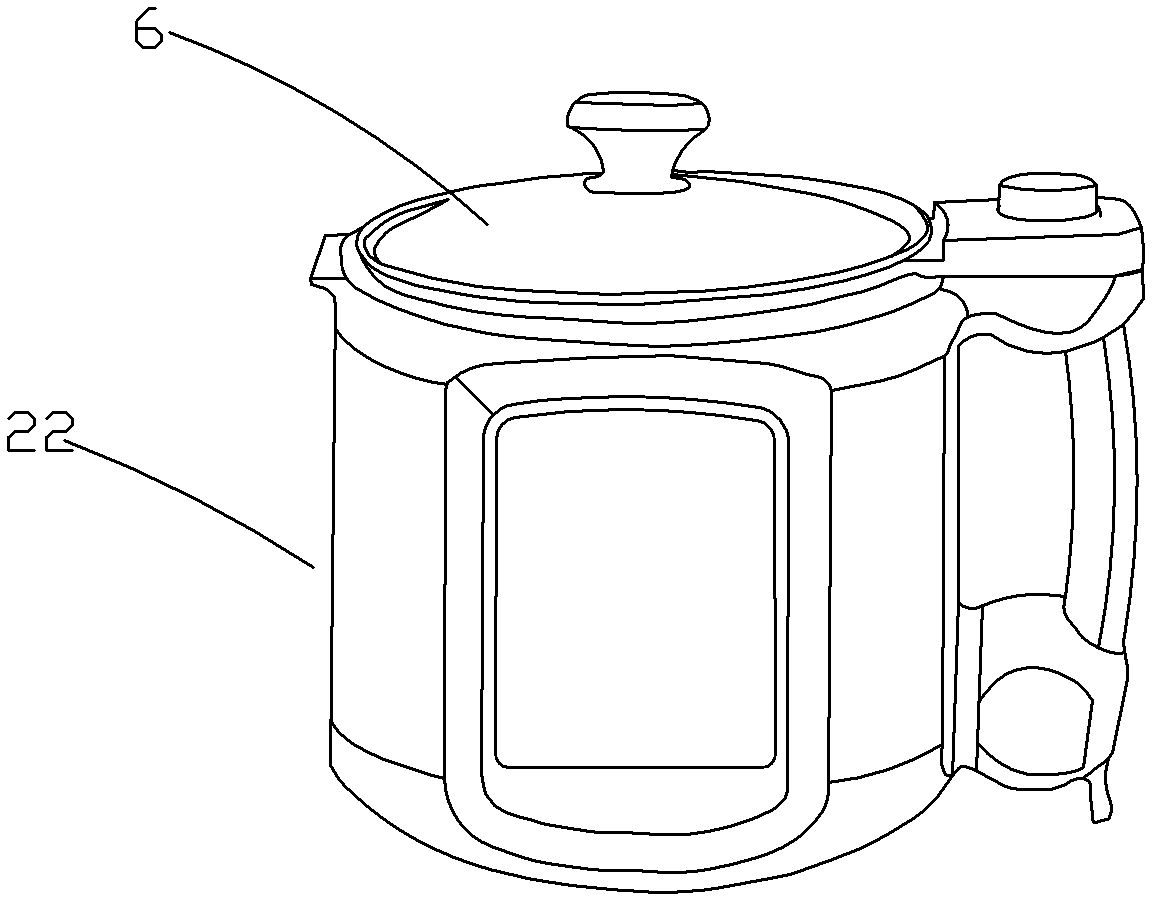

[0024] see Figure 1 to Figure 2 , The soymilk maker with split cup body structure of the present invention includes: a cup body 2 and a machine head 4 buckled on the cup body 2 . The cup body 2 includes a main body 22 and a connecting ring 24 installed on the main body 22 . The head 4 is covered on the connecting ring 24 and electrically connected to the main body 22 .

[0025] The body 22 includes a shell 221 , a PCB board 222 disposed in the shell 221 , a heating device 223 , an inner tank 225 and a heat insulation layer 226 . The PCB board 222 is arranged on the inner bottom of the shell 221, the heating device 223 is arranged on the top of the PCB board and is electrically connected to the PCB board 222, and the inner tank 225 is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com