Horizontal dehydrator

A dehydrator, horizontal technology, applied in the centrifuge and other directions, can solve the problems of screen hole blockage, poor dehydration performance, space blockage, etc., and achieve the effect of preventing screen hole blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The horizontal dehydrator of the present invention will be further described in detail below through specific embodiments.

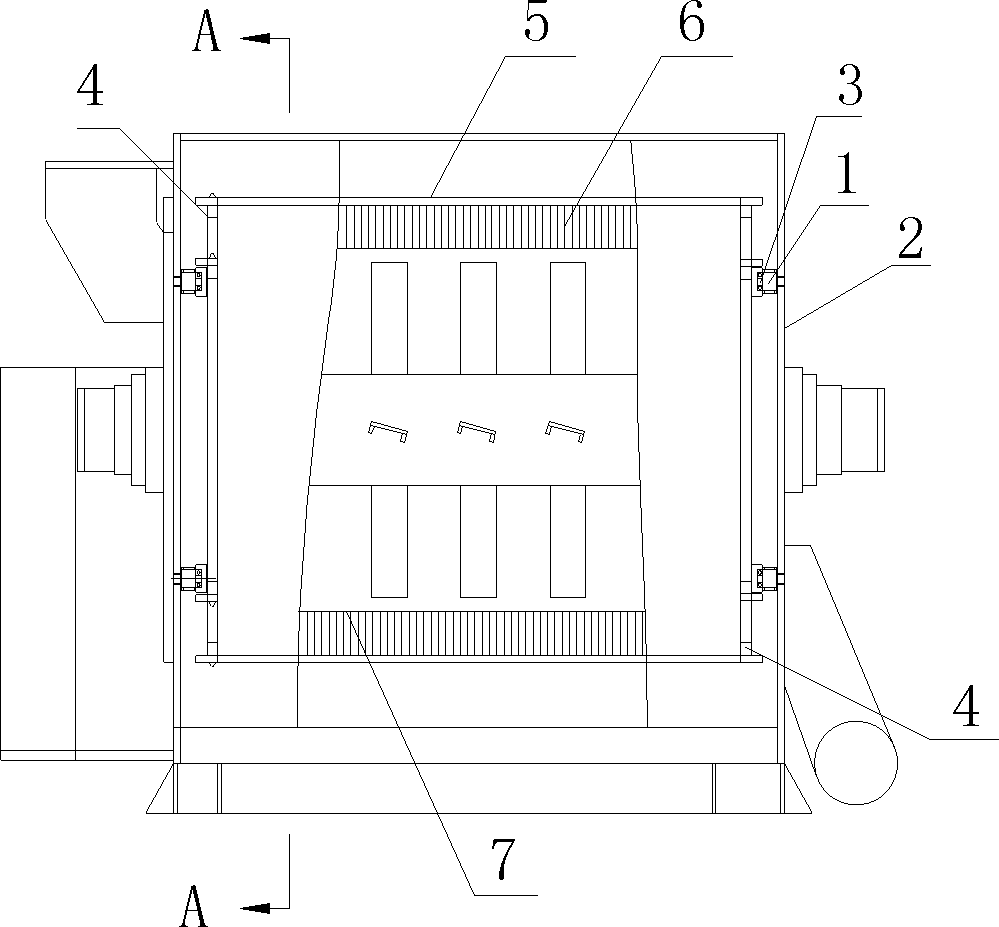

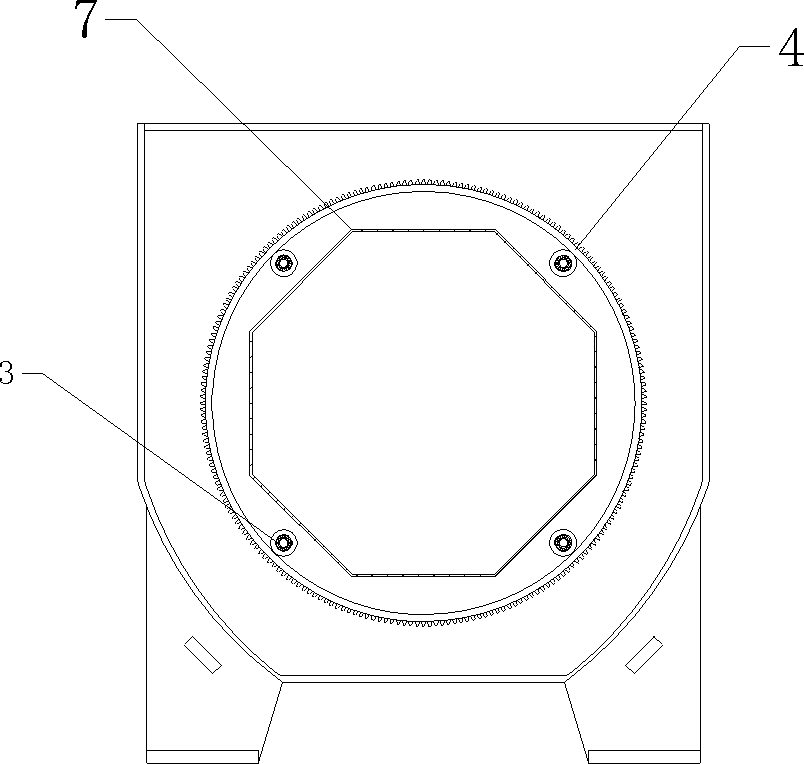

[0012] Such as figure 1 , As shown in 2, the horizontal dehydrator includes a sieve tube 7, in which a rotary centrifugal device is rotatably installed, and both ends of the sieve tube 7 are fixed on the frame by a fixed splint 2. The sieve tube 7 Both ends are sleeved with ring gears 4, and at least two support columns 1 for supporting the ring gear 4 are fixed on each fixing splint 2. In this embodiment, there are 4 support columns. The column 1 is located between the screen cylinder 7 and the gear ring 4. The support column 1 is sleeved with a support bearing 3 on its outer periphery. The support bearing 3 supports the inner wall of the gear ring 4. At least one is installed between the two gear rings 4 The cleaning rod 5 is equipped with a cleaning brush 6 for cleaning the outer peripheral wall of the screen cylinder 7 and the gear ring 4 is driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com