Self-locking hydraulic sliding platform

A hydraulic sliding table, self-locking technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of affecting the quality of processed workpieces, increasing equipment investment costs, affecting processing efficiency, etc., to achieve simple structure , Good locking effect, and the effect of improving the precision of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

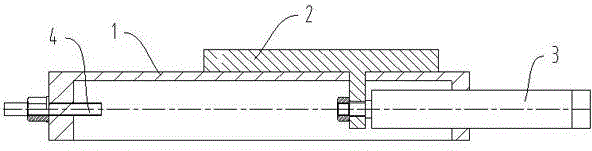

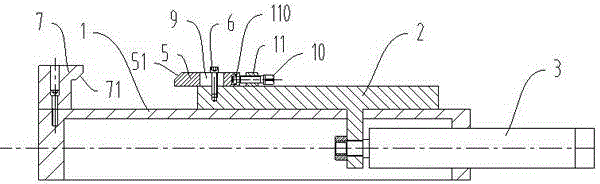

[0014] The working principle of this technology will be further described below with the accompanying drawings.

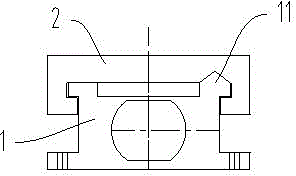

[0015] see Figure 3-5 The self-locking hydraulic slide table shown includes a guide rail body 1, a sliding table 2 sliding along a vertical inverted V-shaped guide rail 11 on the guide rail body, and an oil cylinder 3 for driving the sliding table to move. Adjustment plate 5 is arranged on sliding workbench, and fixed plate 7 is arranged on guide rail body, and two faces of fixed plate and adjustment plate opposite are two matching inclined planes that form 45° with the axis of oil cylinder. When the oil cylinder drives the sliding table to move, the two slopes 71 on the fixed plate 7 contact the slopes 51 on the adjustment plate, and the slopes of the fixed plate generate a downward force on the adjustment plate.

[0016] The adjusting plate is arranged on the sliding workbench by the following structure: the adjusting plate 5 is provided with a slotted hole 9 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com