Buffer plate convenient for sucker to pick in a suction manner and glass transfer package

A buffer sheet and suction cup technology, applied in the field of packaging, can solve problems such as difficult separation, glass fragments, difficulty in taking out and separating glass plates and buffer sheets, etc., to prevent vacuum adsorption problems, solve adhesion fragments when taking pieces, and save taking pieces The effect of working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

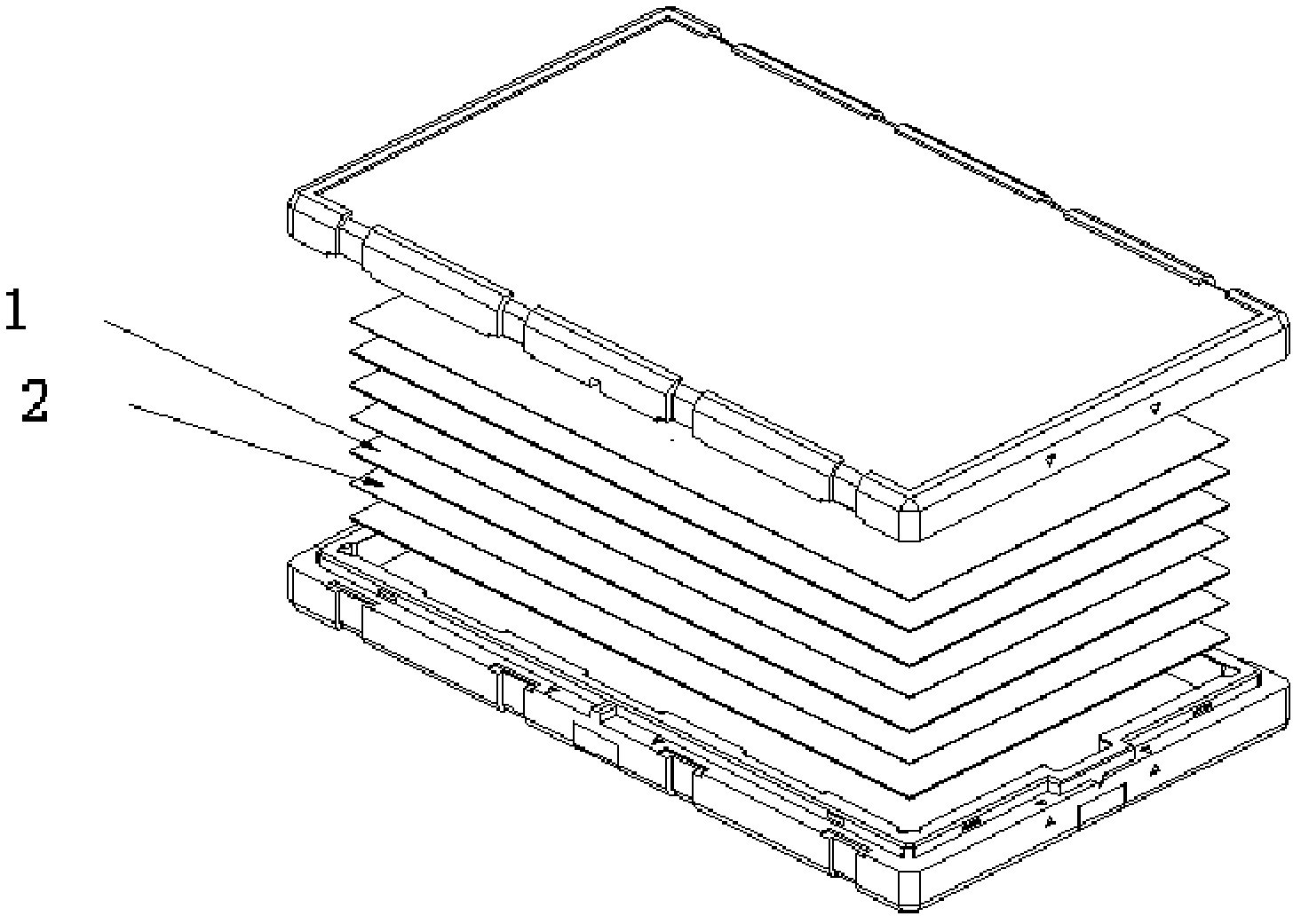

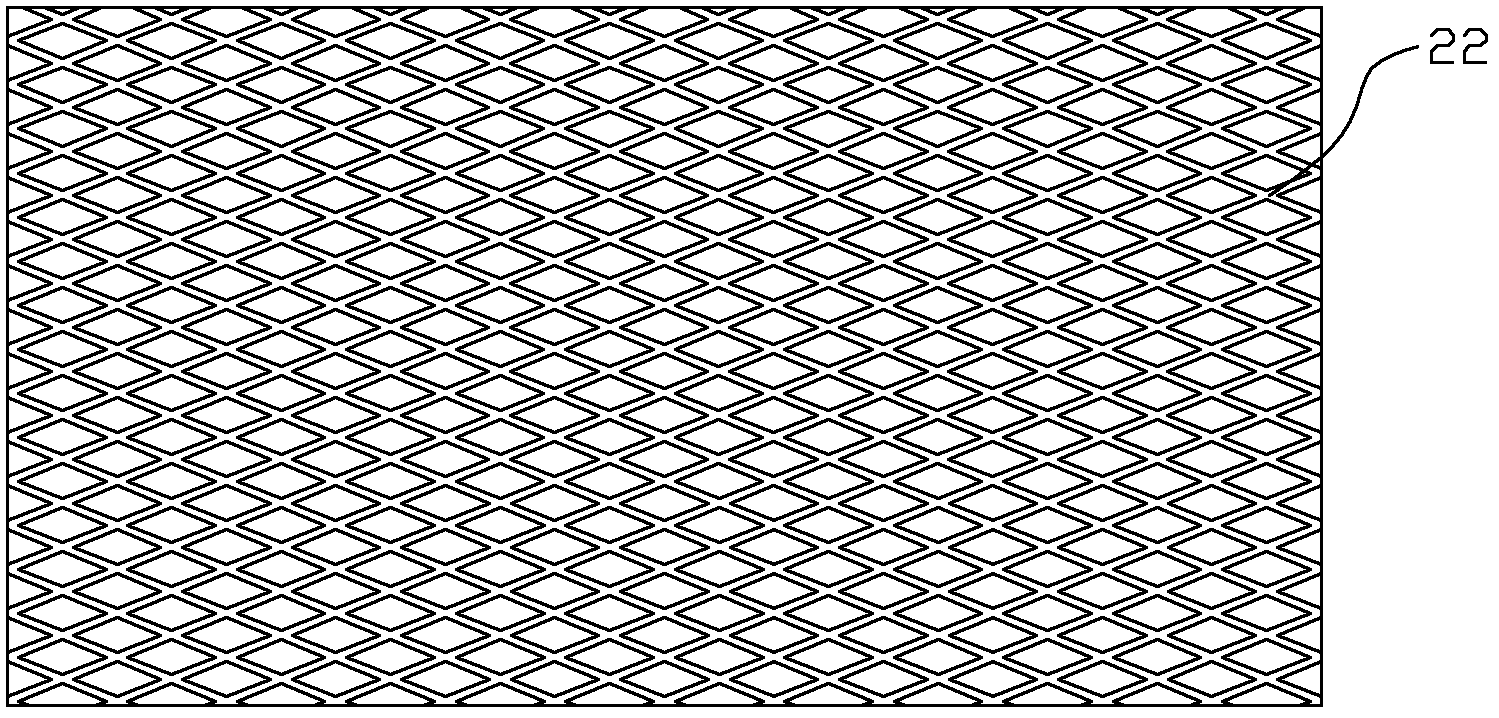

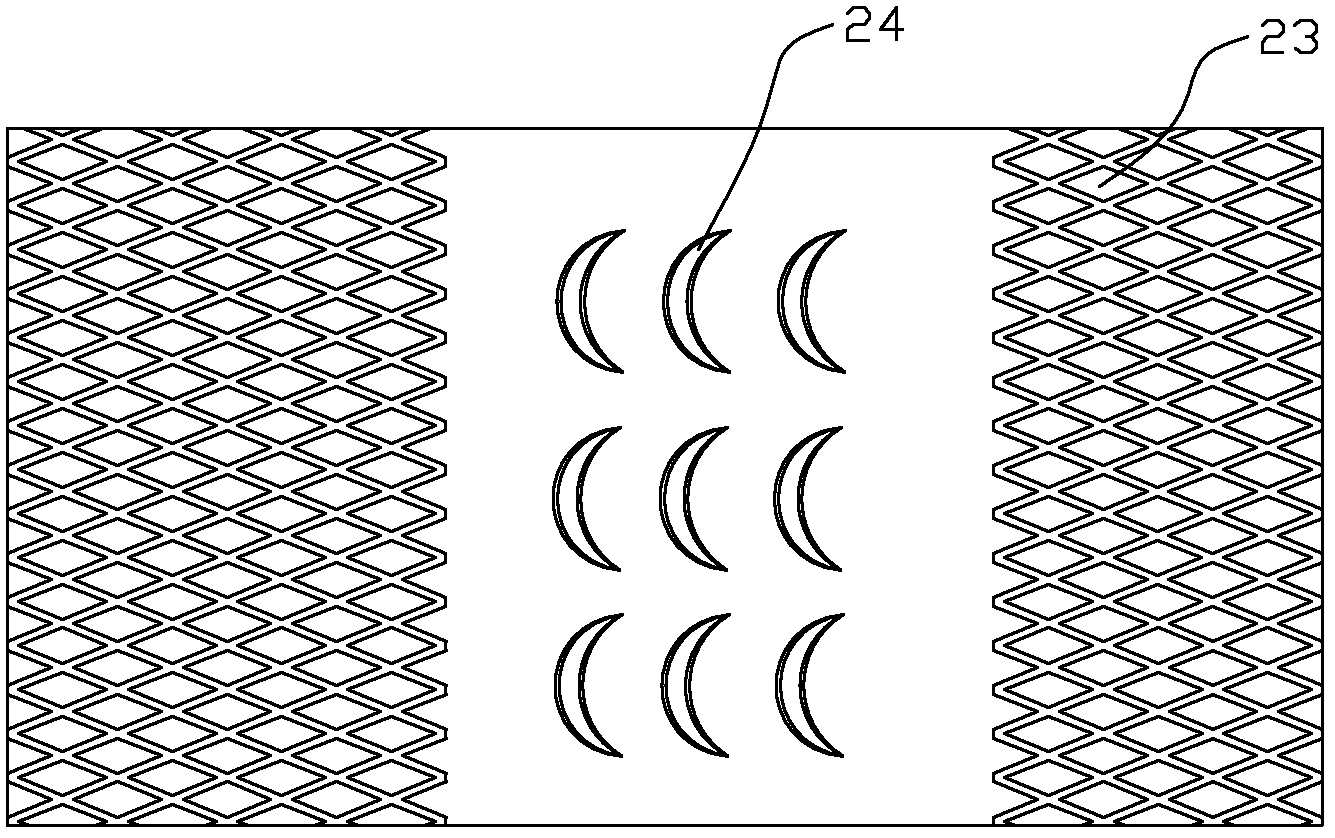

[0029] The invention discloses a liquid crystal glass transfer bag, which includes a glass plate and a buffer sheet, and the buffer sheet is arranged between adjacent glass plates. The liquid crystal glass transfer bag of the invention adopts a buffer sheet with an innovative structure as the present invention Invention of the first embodiment of the cushioning sheet, such as image 3 As shown, the buffer sheet includes a base material and surface textures protruding from the base material. The buffer sheet includes an adsorption area 23 and a non-adsorption area 24. The surface texture of the adsorption area 23 is a closed-cell structure, and the non-adsorption area 23 The surface texture part of the region 24 is an open-pore structure to avoid negative pressure phenomenon, and the surface of the substrate is air-tight. In this embodiment, the non-adsorption area 24 is located in the middle area of the buffer sheet, and the adsorption area 23 is located at both ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com