Technology and system for cooling-absorbing coupling deep-removing tar from biomass gas

A technology of biomass gas and tar, which is applied in the direction of gas dust removal, petroleum industry, and manufacture of combustible gas, etc. It can solve the problems of high viscosity of bio-oil, increase the difficulty of operation and operation, difficulty in continuous and large-scale operation, etc., and achieve wide adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

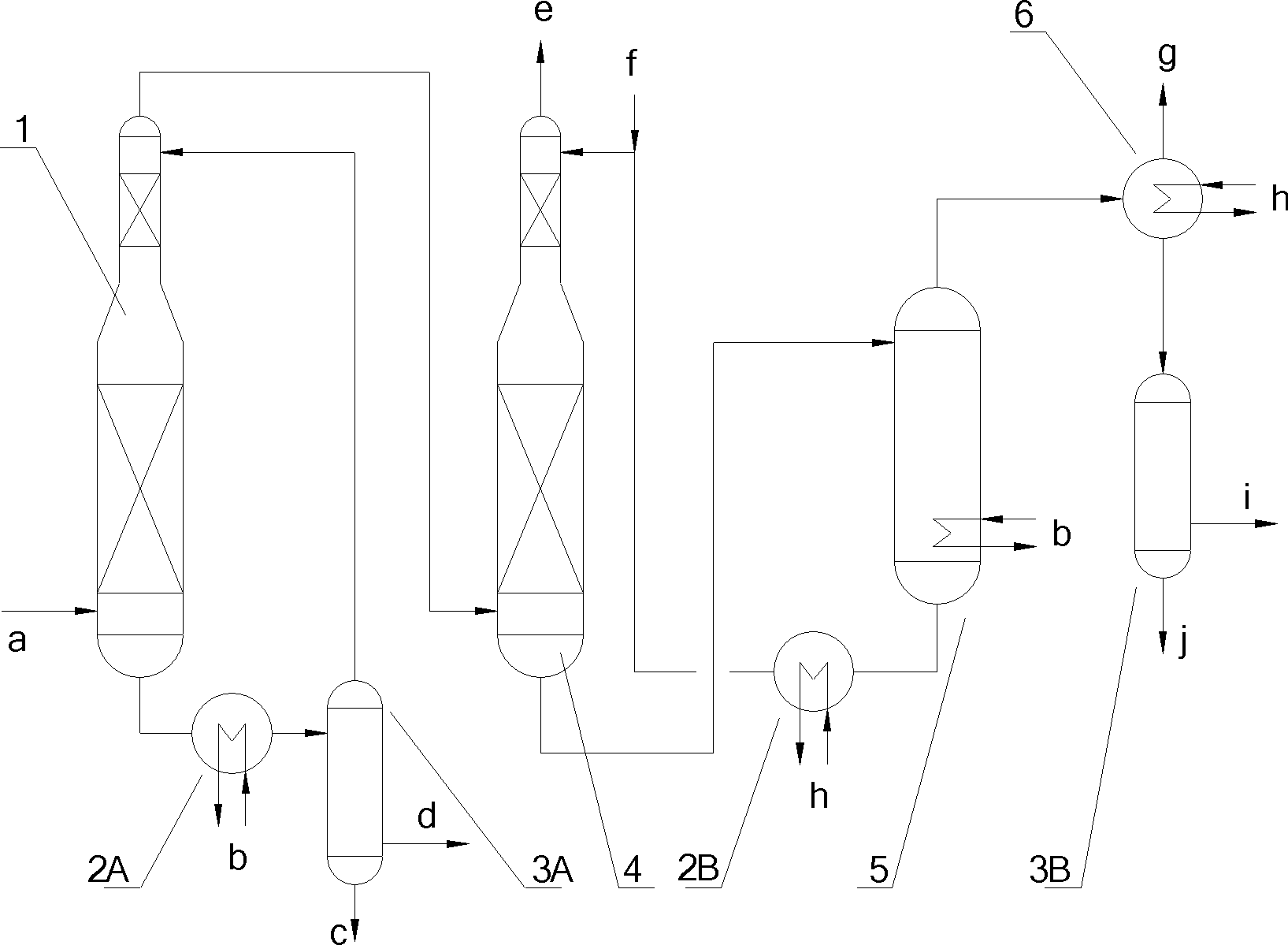

[0026] The schematic diagram of the system of the present invention is as figure 1 As shown, the system for removing tar from biomass gas consists of a spray cooling tower 1, a tar absorption tower 4, a flash tower 5, a first heat exchanger 2A, a second heat exchanger 2B, a heavy tar storage tank 3A and a light The tar storage tank 3B is composed; the spray cooling tower 1 is provided with a lower feed port, a bottom discharge port, a top discharge port and an upper spray feed port, and the heavy tar storage tank 3A is provided with an upper feed port, Top discharge port, bottom discharge port and lower discharge port, tar absorption tower 4 is provided with lower feed port, bottom discharge port, top discharge port and upper spray feed port, tar absorption tower 4 internal loading liquid Phase absorbent f, absorbent f is a mixture of n-propylcyclohexane (5%wt), naphthalene (10%wt) and 1-methyl-2-ethylbenzene (90%wt), with a boiling range of 150 ~180°C; flash tower 5 is provi...

Embodiment 2

[0029] As in the biomass gas detarring system of Example 1, the temperature of the biomass gas is 600°C, and the tar content is 600mg / Nm 3 . The cooling temperature of the first heat exchanger is 140°C; the absorbent is hexadecane with a boiling point of 287°C; the absorption temperature of the tar absorption tower is 25°C; the operating temperature of the flash tower is 135°C. After purification, the tar dew point of biomass gas is reduced to -5°C, and subsequent use will not condense and corrode equipment.

Embodiment 3

[0031] As in the biomass gas detarring system of Example 1, the temperature of the biomass gas is 550°C, and the tar content is 700mg / Nm 3 . The cooling temperature of the first heat exchanger is 120°C; the absorbent is propylbenzene with a boiling point of 160°C; the absorption temperature of the tar absorption tower is 10°C; the operating temperature of the flash tower is 110°C. After purification, the tar dew point of biomass gas is reduced to -2°C, and subsequent use will not condense and corrode equipment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com