Mine filling material and preparation method thereof

A technology for mine filling and construction waste, which is applied to ceramic products, other household appliances, household appliances, etc., to achieve the effects of reducing the generation of waste water, low friction, and reducing filling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

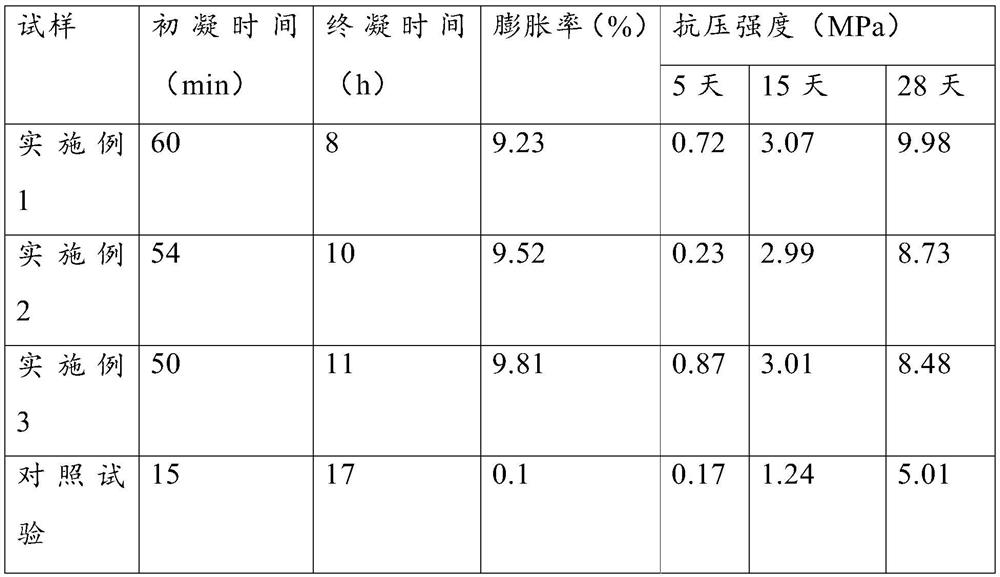

Examples

Embodiment 1

[0033] Preparation of curing agent:

[0034] 25 parts of ettringite, 35 parts of calcium silicate clinker, 15 parts of calcium sulfate, 20 parts of quicklime, and 0.5 part of aluminum powder, crushed and ground to a particle size of less than 100 mesh, and set aside.

[0035] Master batch preparation:

[0036] Take 95 parts of curing agent, 0.1 part of rheology modifier, 0.5 part of coagulation regulator and 0.1 part of defoamer, mix evenly, grind until the particle size is less than 100 mesh, and make a masterbatch;

[0037] Preparation of excipients:

[0038] Reinforced concrete blocks in construction waste are forged by forging equipment or cracked by electric hammer, sieved after magnetic separation, sorted and sieved by division of labor, and then forged or cracked, sieved and magnetically separated; steel bars, aluminum alloys, Wood blocks, plastics, PVC pipes, iron and steel substances, other metal substances, large pieces of plastic, paper or recyclable waste product...

Embodiment 2

[0043] Preparation of curing agent:

[0044] 35 parts of ettringite, 25 parts of calcium silicate clinker, 25 parts of calcium sulfate, 15 parts of quicklime, and 1 part of aluminum powder, crushed and ground to a particle size of less than 100 mesh, and set aside.

[0045] Master batch preparation:

[0046] Take 90 parts of curing agent, 0.5 part of rheology modifier, 0.1 part of coagulation regulator and 0.5 part of defoamer, mix them evenly, grind until the particle size is less than 100 mesh, and make a masterbatch;

[0047] Preparation of excipients:

[0048] Reinforced concrete blocks in construction waste are forged by forging equipment or cracked by electric hammer, sieved after magnetic separation, sorted and sieved by division of labor, and then forged or cracked, sieved and magnetically separated; steel bars, aluminum alloys, Wood blocks, plastics, PVC pipes, iron and steel substances, other metal substances, large pieces of plastic, paper or recyclable waste prod...

Embodiment 3

[0053] Preparation of curing agent:

[0054] 30 parts of ettringite, 30 parts of calcium silicate clinker, 20 parts of calcium sulfate, 20 parts of quicklime, and 0.8 part of aluminum powder, crushed and ground to a particle size of less than 100 mesh, and set aside.

[0055] Master batch preparation:

[0056] Take 90 parts of curing agent, 0.3 part of rheology modifier, 0.4 part of coagulation regulator and 0.4 part of defoamer, mix them evenly, grind until the particle size is less than 100 mesh, and make a masterbatch;

[0057] Preparation of excipients:

[0058] Reinforced concrete blocks in construction waste are forged by forging equipment or cracked by electric hammer, sieved after magnetic separation, sorted and sieved by division of labor, and then forged or cracked, sieved and magnetically separated; steel bars, aluminum alloys, Wood blocks, plastics, PVC pipes, iron and steel substances, other metal substances, large pieces of plastic, paper or recyclable waste pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com