Cellulose-producing strain, cellulose and method for producing and fermenting cellulose

A technology for cellulase, fermentation and culture, applied in microorganism-based methods, biochemical equipment and methods, enzymes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Physiological and biochemical characteristics of cellulase-producing strain 48-1

[0039] A cellulase-producing bacterial strain numbered 48-1 was obtained from the surface of flue-cured tobacco in Yuxi, purified and screened. The bacterial strain has been preserved in the "General Microorganism Center of China Committee for Culture Collection of Microorganisms" (Beijing, China), and the preservation number is: CGMCC No.5311.

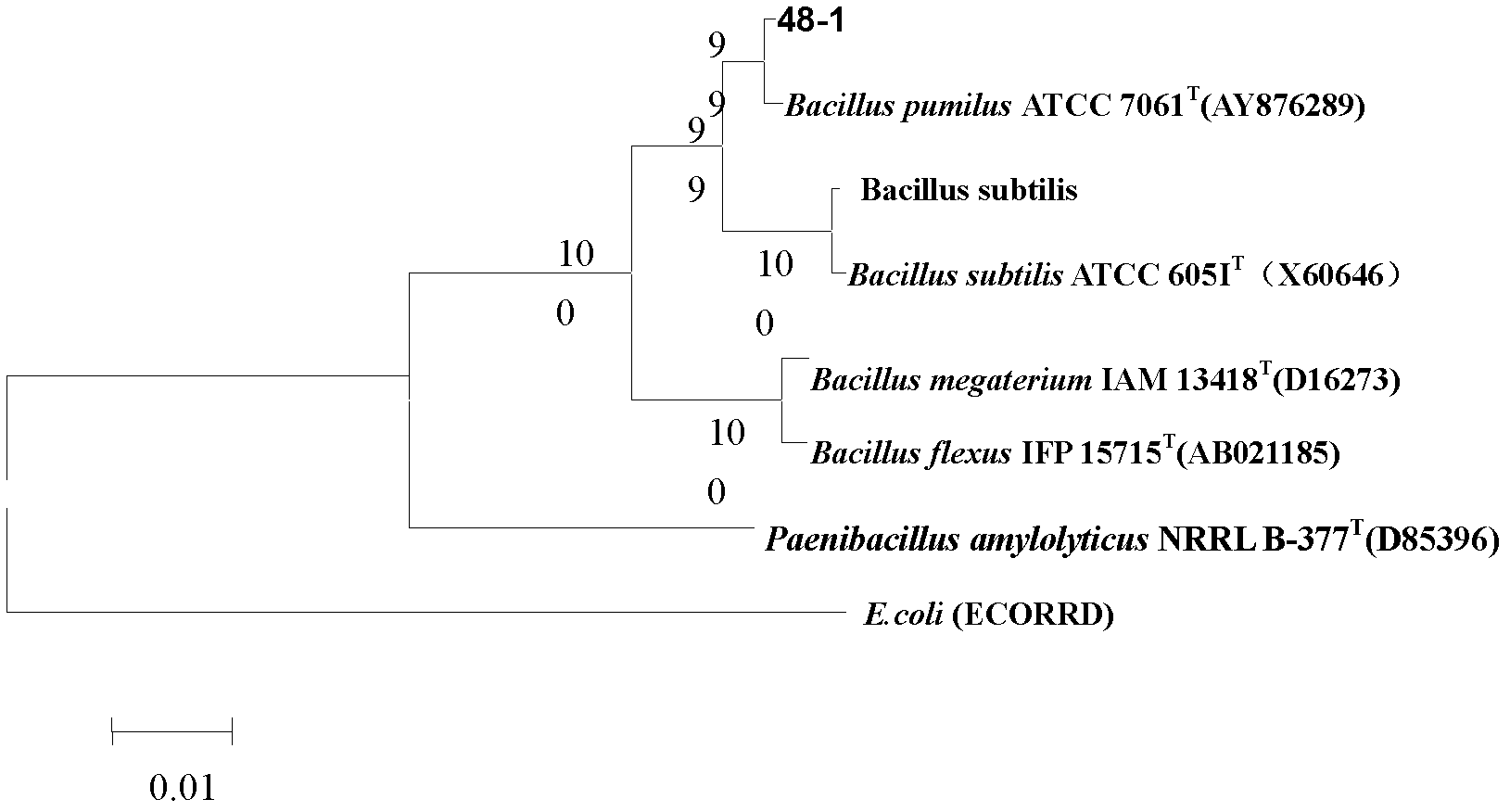

[0040]The colony of strain 48-1 is round, white, raised, with a size of 5.0-6.0 mm, shiny, opaque and sticky. The bacterial strain can grow at a temperature of 10-35 DEG C and a pH range of 4.5-9.5. The 16S rDNA sequences of the bacteria were submitted to the NCBI database, and the homologous sequence alignment search (BLAST) was performed in GenBank, and the 16S rDNA sequences of the microbial model strains of related groups were downloaded. The ClustalX software was used to compare the 16S rDNA sequence with the 16S rDNA sequence of the type ...

Embodiment 2

[0044] Screening and Fermentation Conditions of Cellulase Producing Strain 48-1

[0045] The isolated bacterial strain is inoculated on the LB medium that contains 1% sodium carboxymethylcellulose (CMC), and its composition is: yeast powder 5g, peptone 10g, sodium chloride 10g, 0~35 ℃ cultivated 12 hours, When the diameter of the colony is about 3-6 mm, stain with 0.2% Congo red solution for 2 hours, then decolorize with 5% NaCl solution for 1 hour, then measure the size of the hydrolysis circle and the diameter of the strain, and calculate the ratio of the hydrolysis circle and the diameter of the strain. Generally speaking, the ratio is related to the strain's ability to degrade cellulose. The larger the ratio of the hydrolysis circle to the diameter of the strain, the stronger the ability of the strain to degrade cellulose and the stronger the ability to secrete cellulase.

[0046] The re-screening of cellulase-producing strains is carried out by the method of measuring en...

Embodiment 3

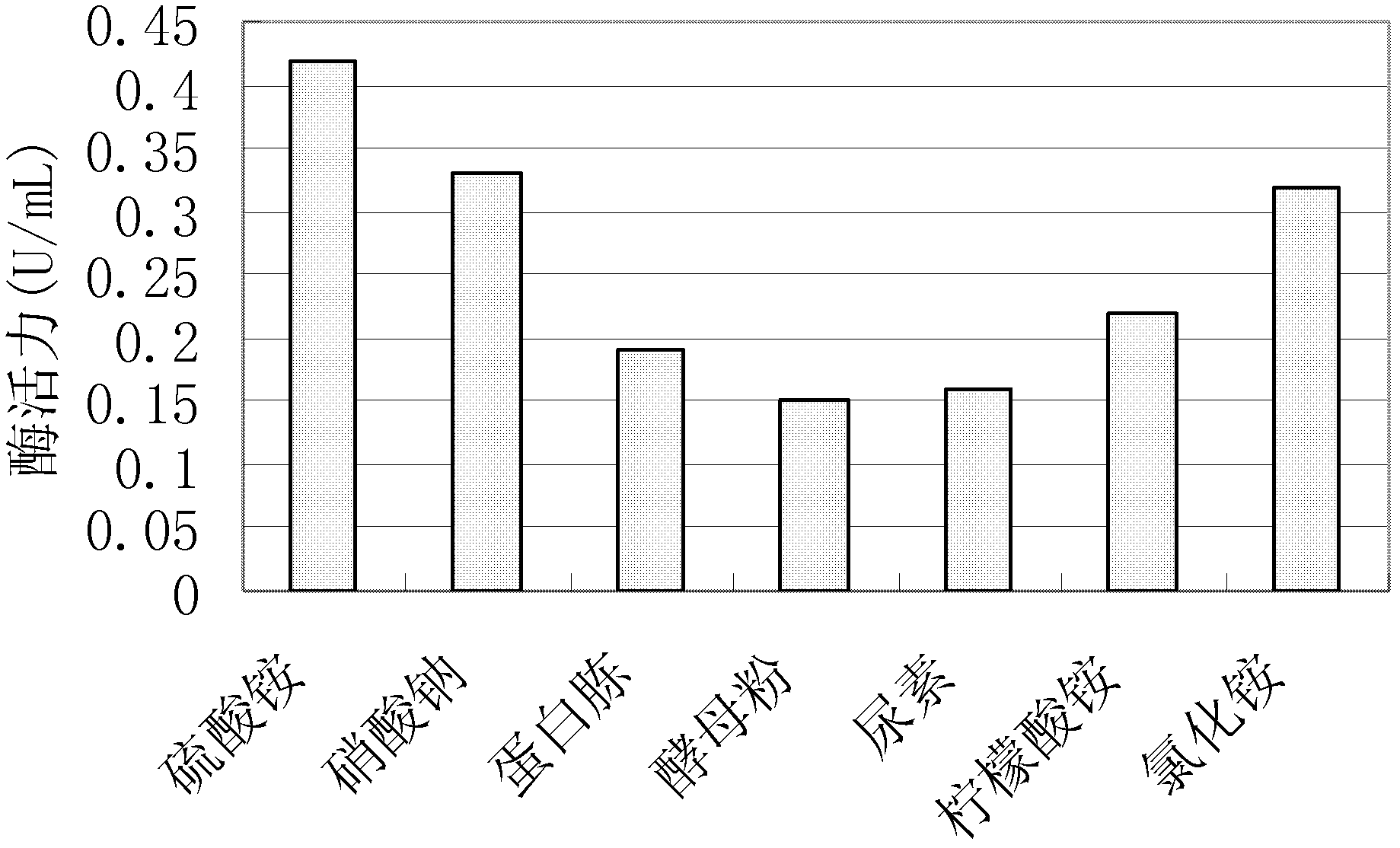

[0048] Optimization of Enzyme Production Conditions of High Cellulase Producing Strain 48-1

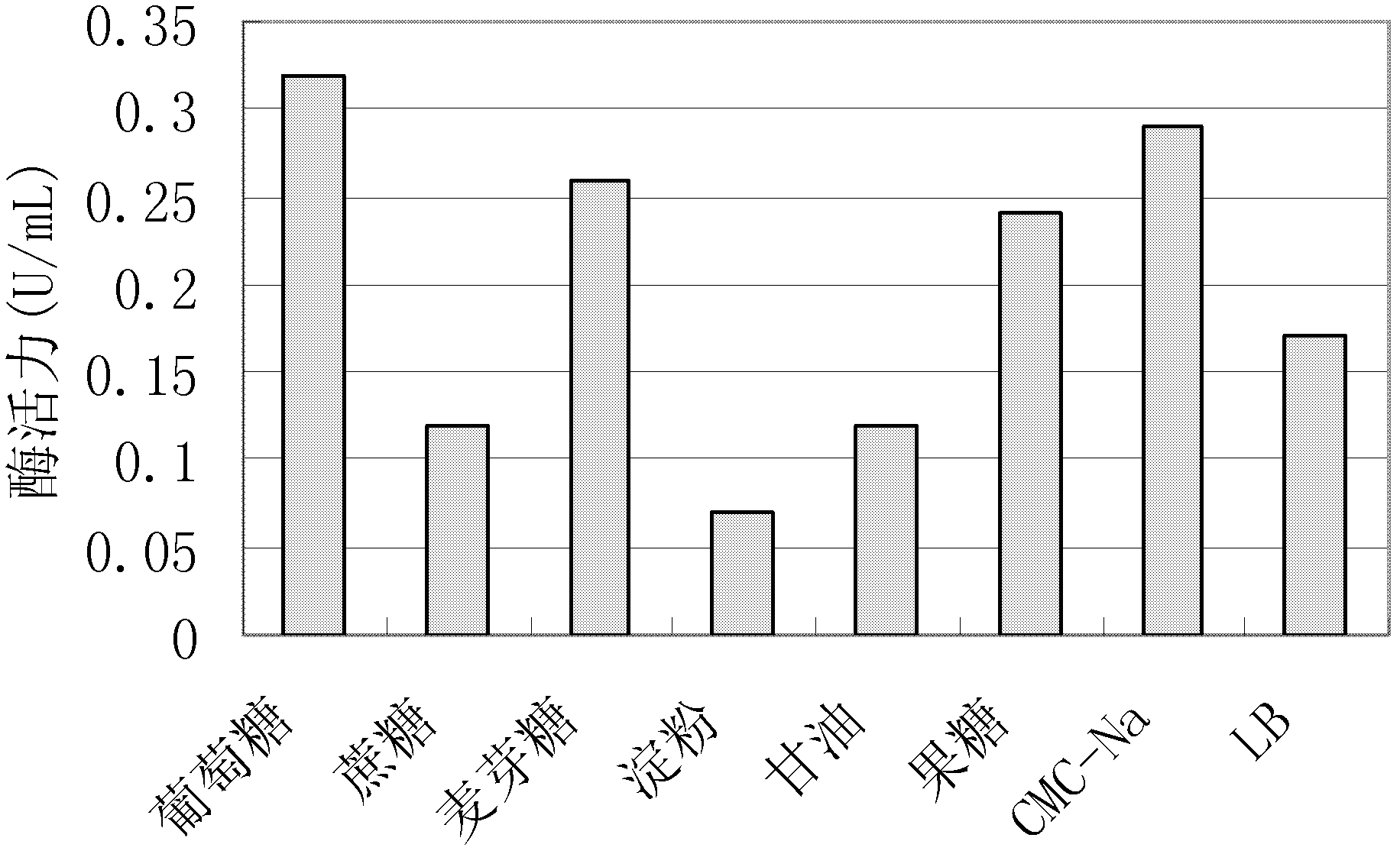

[0049] Effect of carbon source on enzyme production:

[0050] Basal medium A: yeast powder 0.2g / L, potassium chloride 0.5g / L, dipotassium hydrogen phosphate 1g / L, sodium nitrate 1g / L, magnesium sulfate 0.4g / L, ferrous sulfate 0.01g / L. Add glucose, sucrose, maltose, starch, glycerol, fructose and CMC-Na respectively (final concentration 1g / L), pH 7.0. Use an inoculation needle to pick up a little lawn from the slant of the 48-1 strain and insert it into the liquid LB medium, and culture it with shaking at 37°C for 2-3 days. Then inoculated into basal medium A according to the inoculum amount of 1%, and cultured with shaking at 37°C for 2 days. The cellulase activity in each fermentation broth was detected by DNS method. The results showed that among the various carbon sources, the enzyme activity of glucose was the highest, followed by maltose, and the production of sucrose, starch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com