Profiled groove end surface non-contact mechanical seal with backflow function

A mechanical seal, non-contact technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of high difficulty in implementation, inconspicuous lubricating effect and return effect, and high cost of pumping return type tank technology, to achieve Uniform pressure distribution, improve the carrying capacity of the fluid film, and improve the effect of the pumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

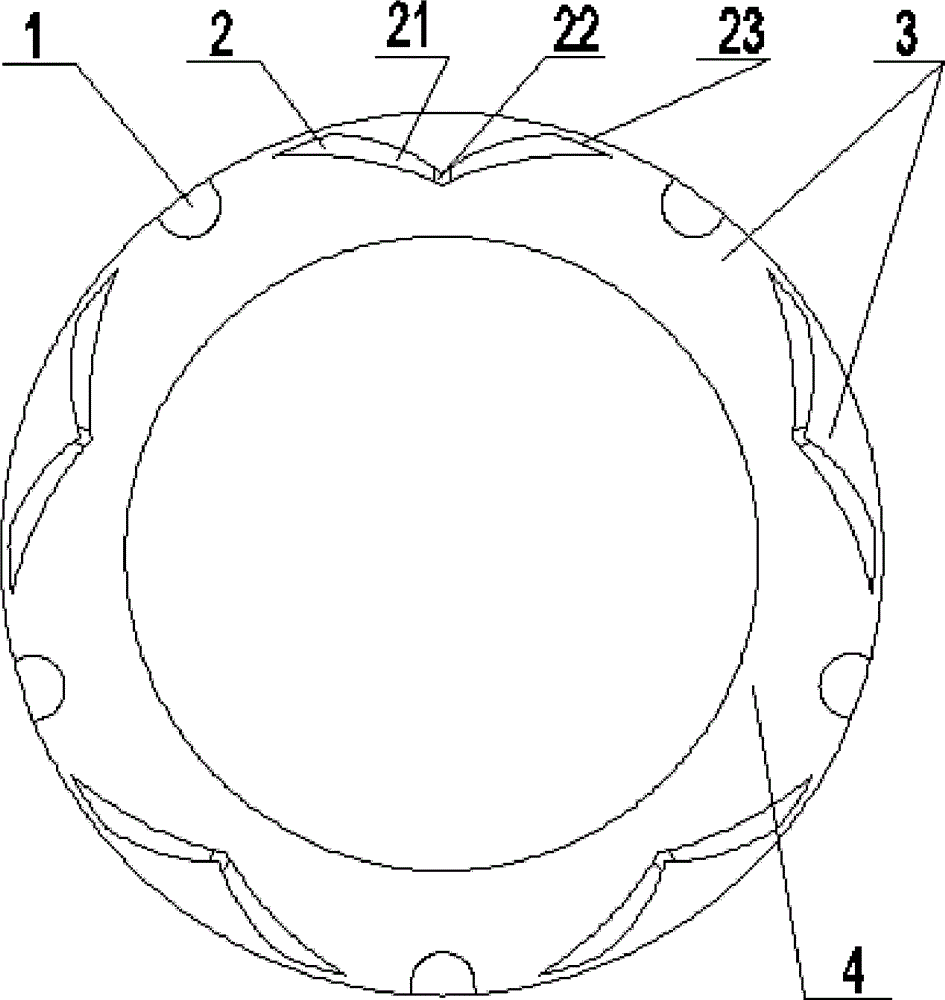

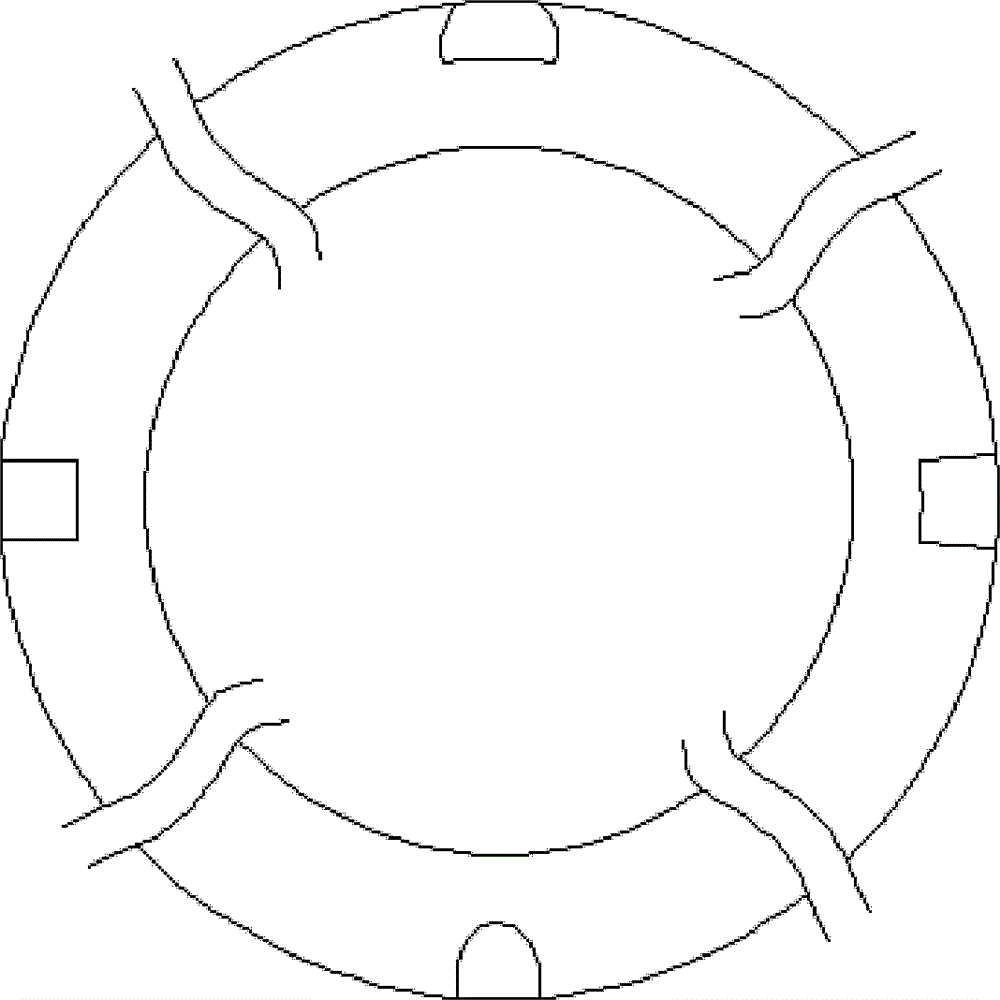

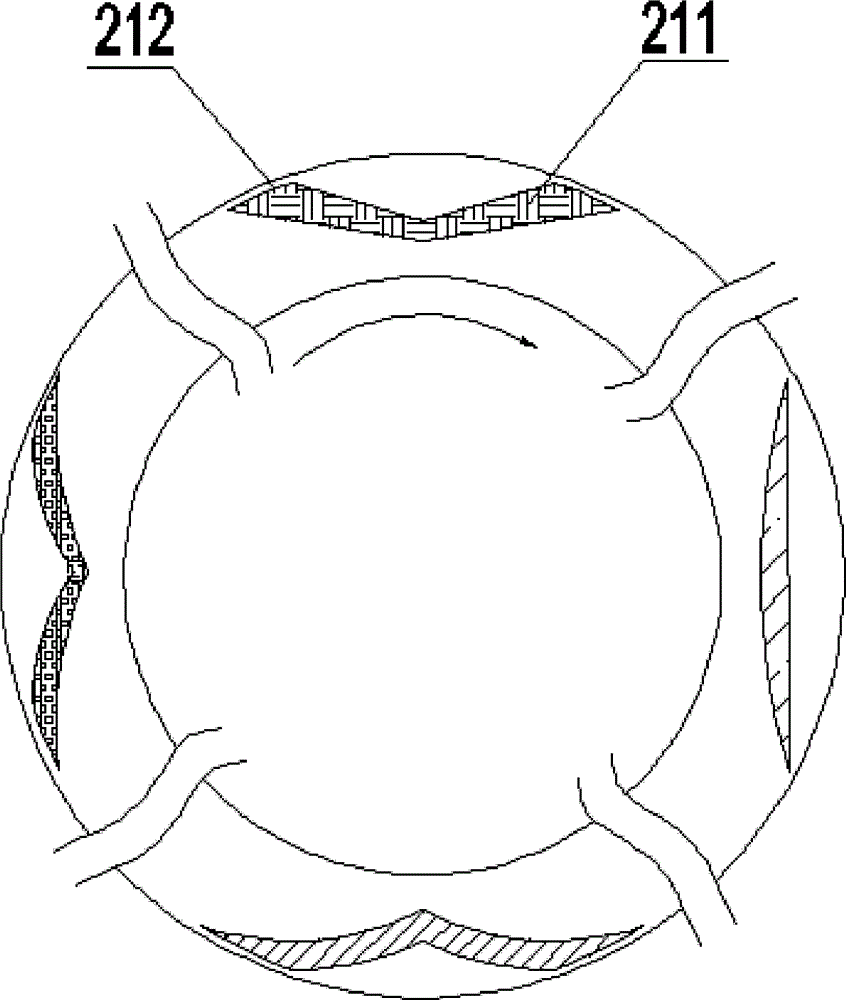

[0028] refer to Figure 1-3 , a grooved end face non-contact mechanical seal with backflow function, including a moving ring and a static ring of the mechanical seal, one side of the end faces of the moving ring and the static ring is the high pressure side, that is, the upstream, the moving ring and the static ring The other side of the end face of the ring is the low-pressure side, that is, the downstream side. A smooth and flat annular sealing dam 4 is provided downstream of the end face, and multiple sets of fluid-type grooves are provided on at least one sealing end face of the moving ring or static ring. The fluid-type grooves are periodically arranged along the circumferential direction of the end surface, and the feature is that: the fluid-type grooves are composed of a drainage groove 1 and a pumping return groove 2, and the average groove depth of the drainage groove 1 is greater than that of the pumping The average groove depth of the reflux groove; the drainage gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com