Stop valve with valve seat provided with protective sleeve

A technology of sheath pipe and stop valve, which is applied in the structural field of stop valve, can solve the problems affecting the tightness of closing, the defect of the sealing surface of the valve seat, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

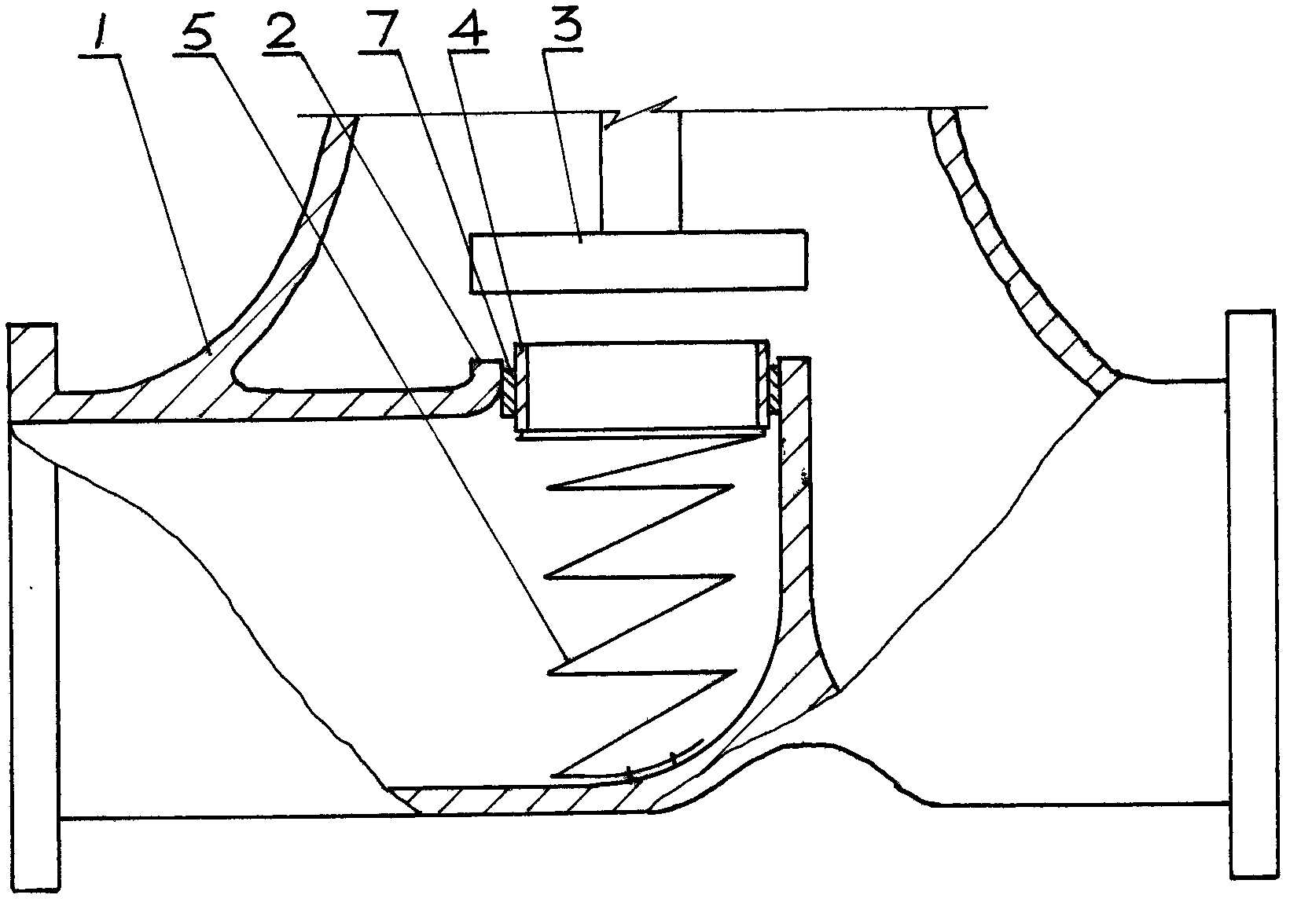

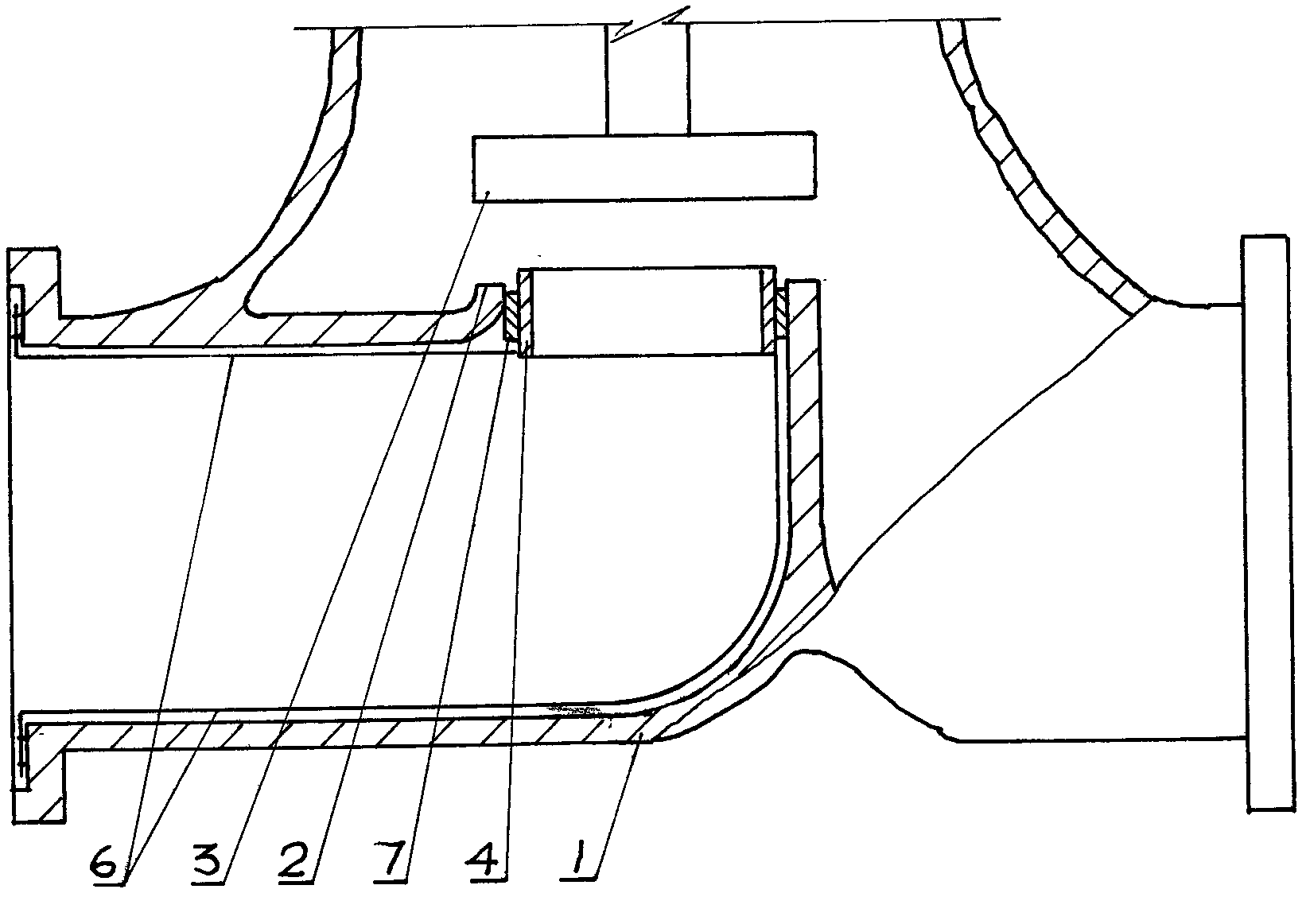

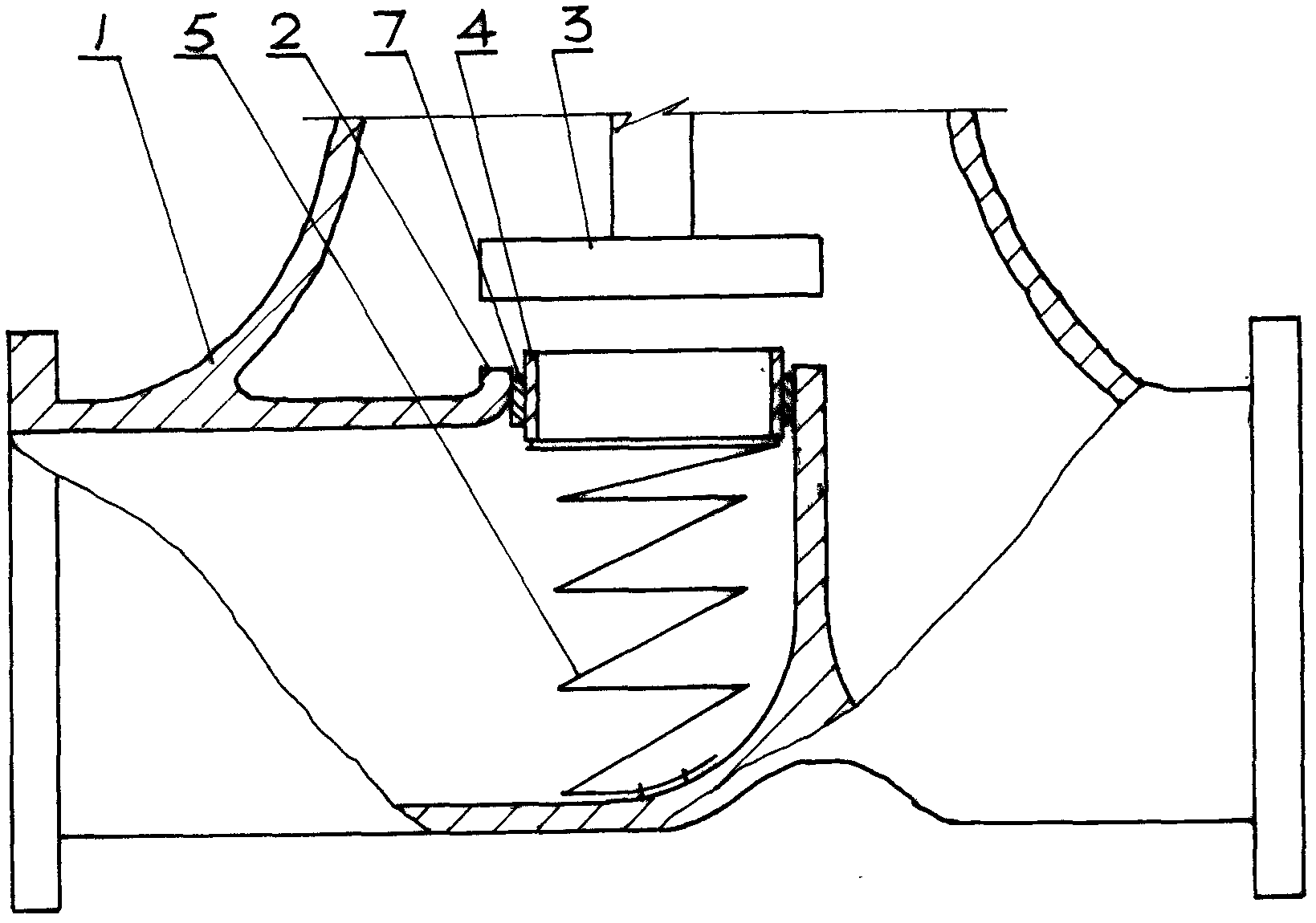

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0012] Because the added parts of the present invention will work under the situation of being immersed in fluid together with parts such as valve plate 3, so its performances such as temperature resistance, corrosion resistance and rigidity should be suitable for. The connection between the fixed sleeve 7 and the inner ring of the valve seat 2 can be realized by welding or bonding, and must be firm and reliable. The connection of the spring 5, the elastic rod 6 and the valve body should be screwed, because the sheath pipe 4, the spring 5 and the elastic rod 6 are easily damaged and can be easily replaced. according to figure 1 and figure 2 As shown, when the valve plate 3 is opened, the sheath tube 4 rises under the support of the spring 5 or the elastic rod 6 to block the sealing surface of the valve seat 2, and the fluid bypasses the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com