Device and method for quickly dispersing sand grains

A technology of sediment particle and dispersing device, which is applied in the direction of analysis materials, preparation of test samples, instruments, etc. It can solve the problems that it is difficult to satisfy the sufficient dispersion of sediment particles, affect the analysis of sediment particles, and overlap the sediment particles. , to achieve the effects of promoting the use, improving measurement automation, and being easy to build

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

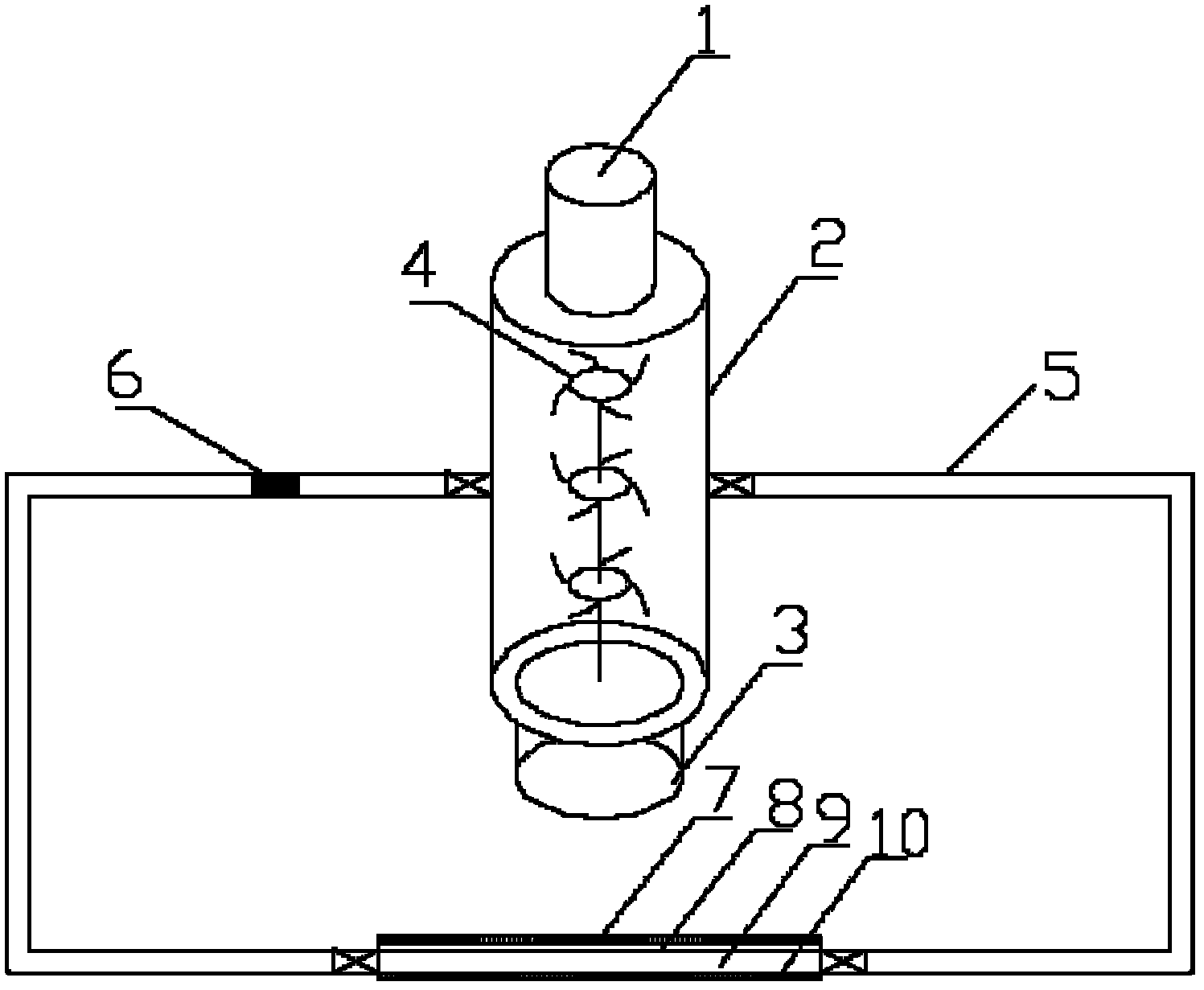

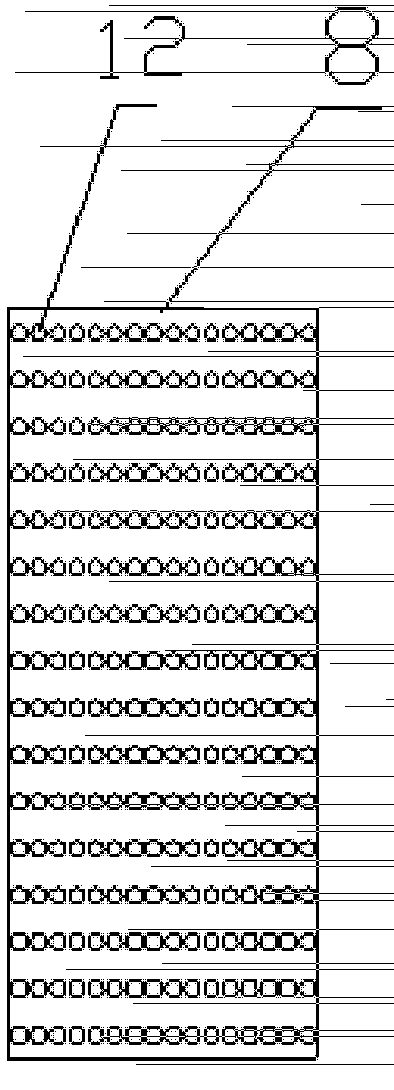

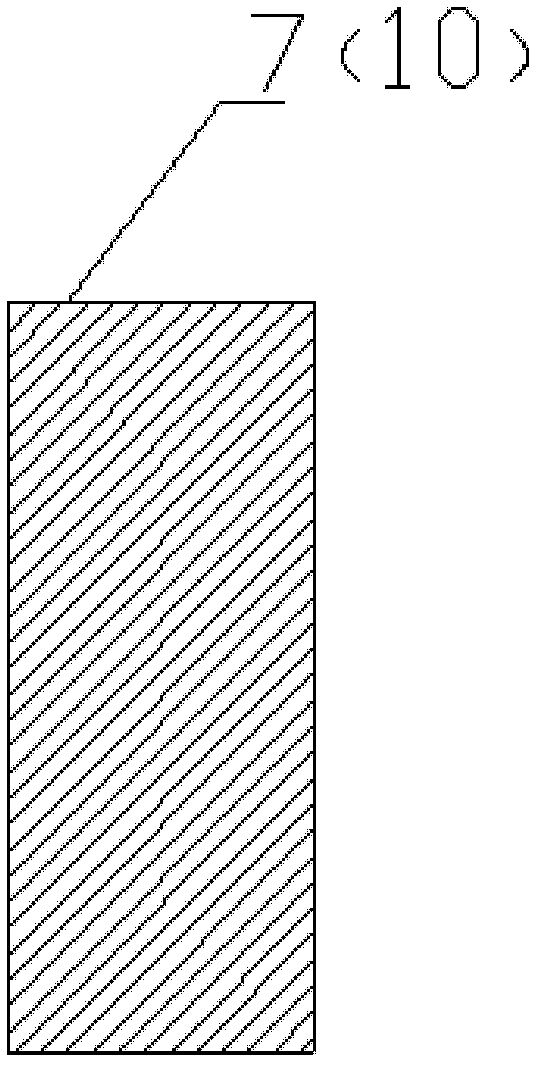

[0016] Such as Figures 1 to 3 As shown, the rapid dispersion device for sediment particles of the present invention includes a connection hole 1, a mixing tank 2, a micro-pipeline pump 6 and a dispersion bin 9, and the mixing tank 2, the micro-pipeline pump 6 and the dispersion bin 9 form a connection circuit through a connecting pipe 5 , the mixing tank 2, the micro pipeline pump 6 and the dispersion chamber 9 are respectively equipped with electric valves; the mixing tank 2 is installed on the base 3, the mixing tank 2 is provided with an agitator 4, and the top of the dispersion chamber 9 is sequentially provided with a dispersion plate 8 and a barrier glass plate 7, a glass bottom plate 10 is provided below the dispersion chamber 9.

[0017] Wherein, the height of the internal space of the dispersion chamber 9 is adjusted according to the particle size range of the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com