Industrial ray detection negative film digital device

A technology of radiographic detection and negative film, which is applied in the field of digital device for industrial radiographic detection negative film, can solve the problems of unstable transmission ratio, low transmission efficiency, and low degree of automation, so as to improve reliability and sensitivity, improve transmission efficiency, and improve film feeding efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

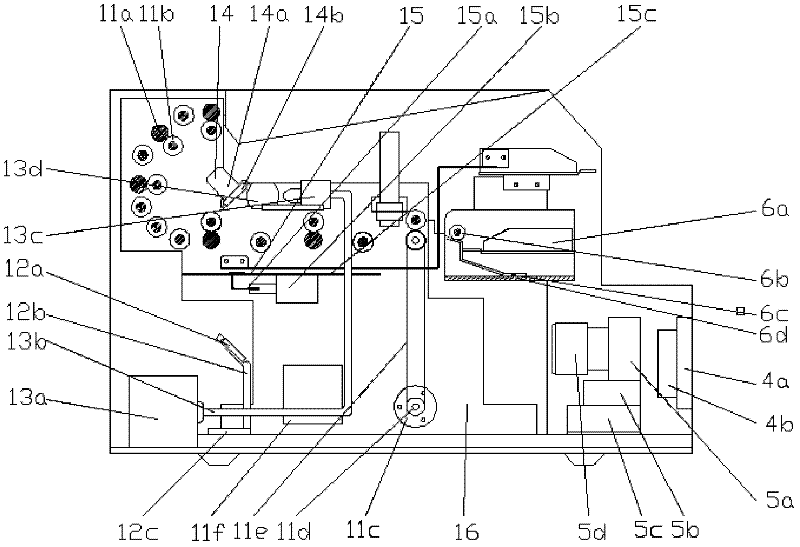

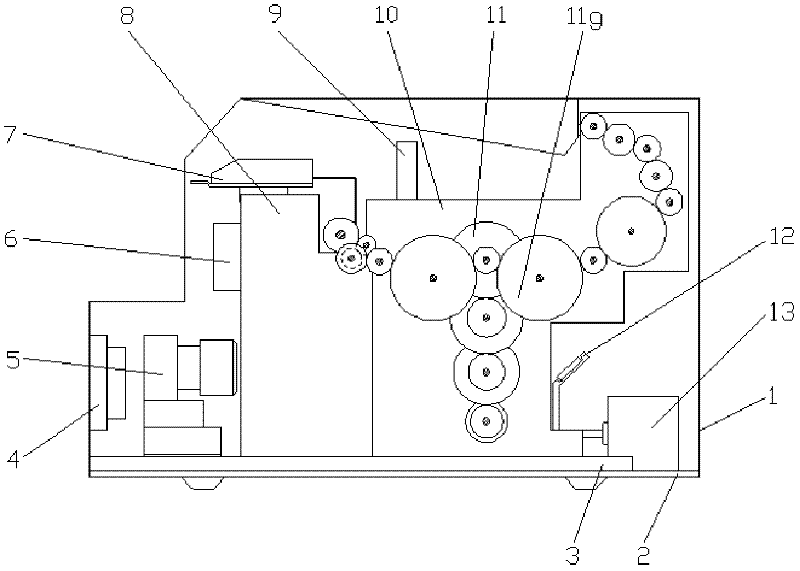

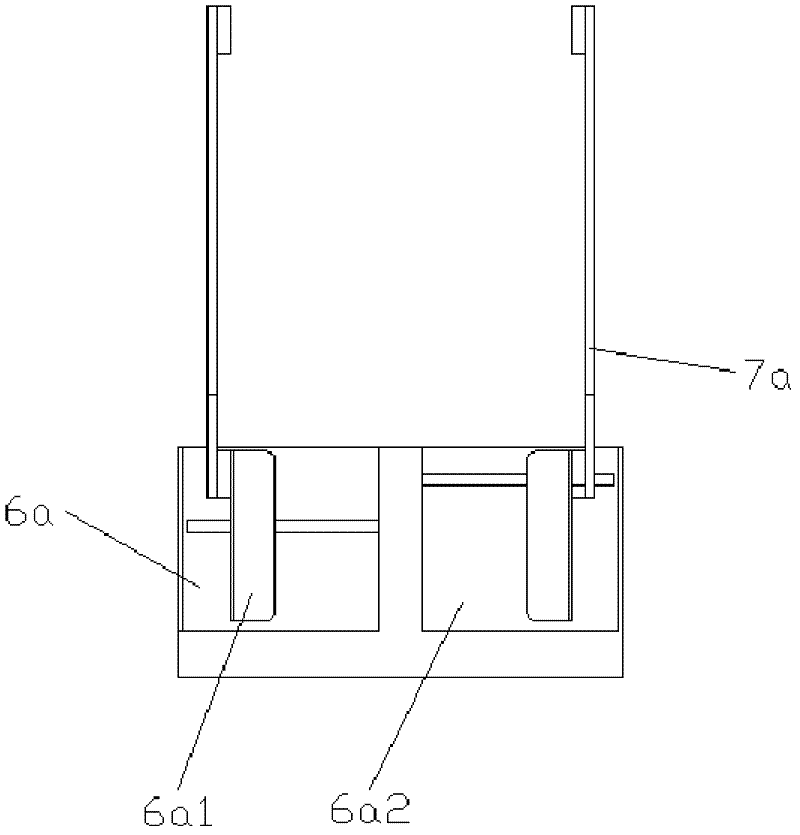

[0026] refer to figure 1 , figure 2 As shown, the automatic film feeding mechanism 6 and the linkage shading mechanism 7 are fixed on the front side plate 8 , the cooling device 4 is fixed on the shell 1 , and the optimized digital acquisition module 16 is fixed on the bottom plate 3 . The heat sink 4 includes a filter screen 4a and a fan 4b.

[0027] The shell 1 and the shell bottom plate 2 are used as the outer cover of the device, the bottom plate 3 is fixed on the shell bottom plate 2, the optimized digital acquisition module 16 is fixed on the top of the bottom plate 3, and the front side plate 8 and the rear side plate 10 are respectively fixed on the front and rear sides of the bottom plate 3. The left and right ends of the base plate 3 are respectively fixed with the lower reflector device 12 and the acquisition device 5 . The linkage light-shield...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com