Industry radiographic inspection negative film digitalizer

A radiation detection and industrial technology, which is applied in the field of industrial radiation detection film digital devices, can solve the problems of unstable transmission ratio, manual adjustment of shading devices, and less adjustment freedom, so as to improve reliability and sensitivity, and improve optical path adjustment efficiency , The effect of improving the film feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

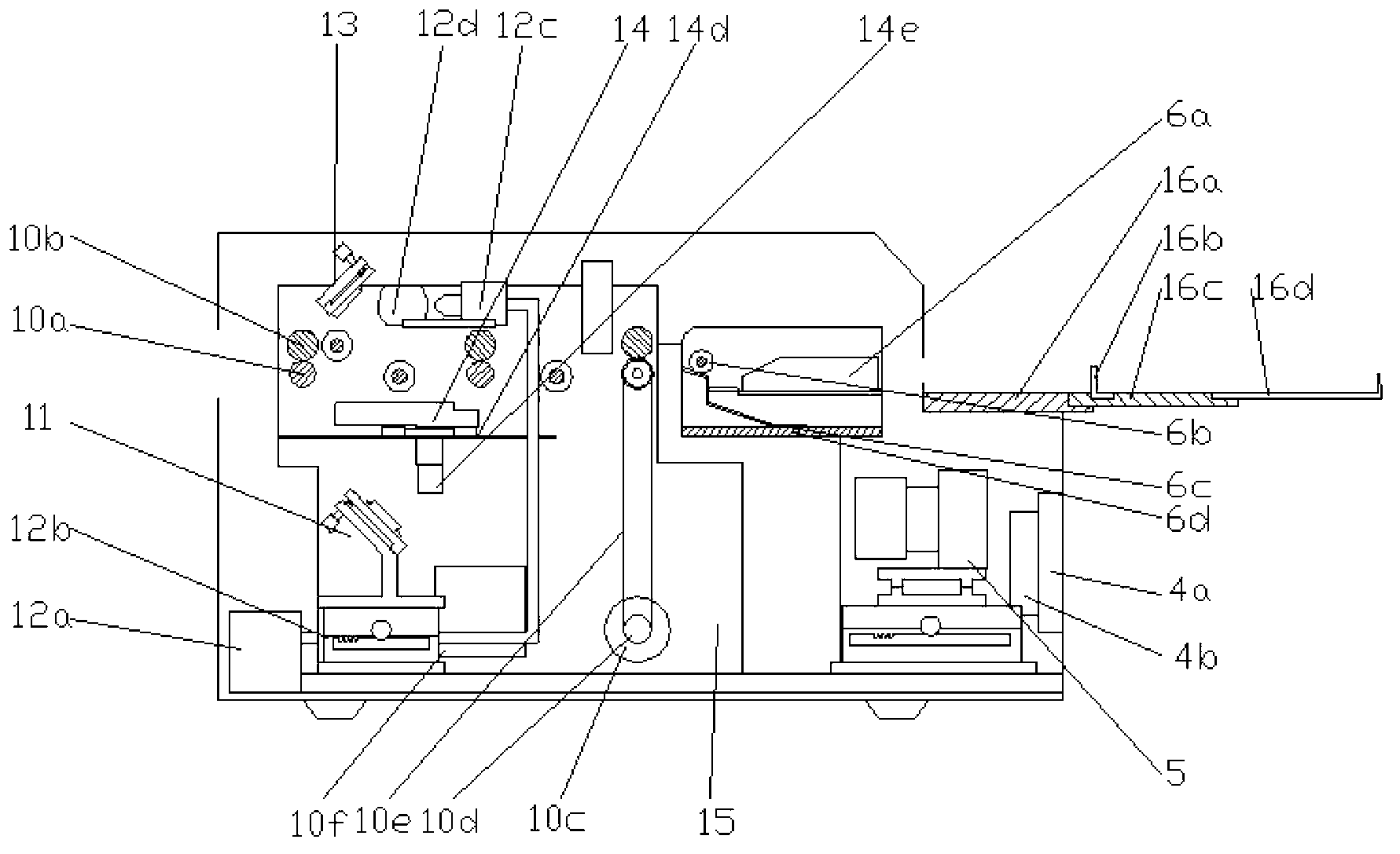

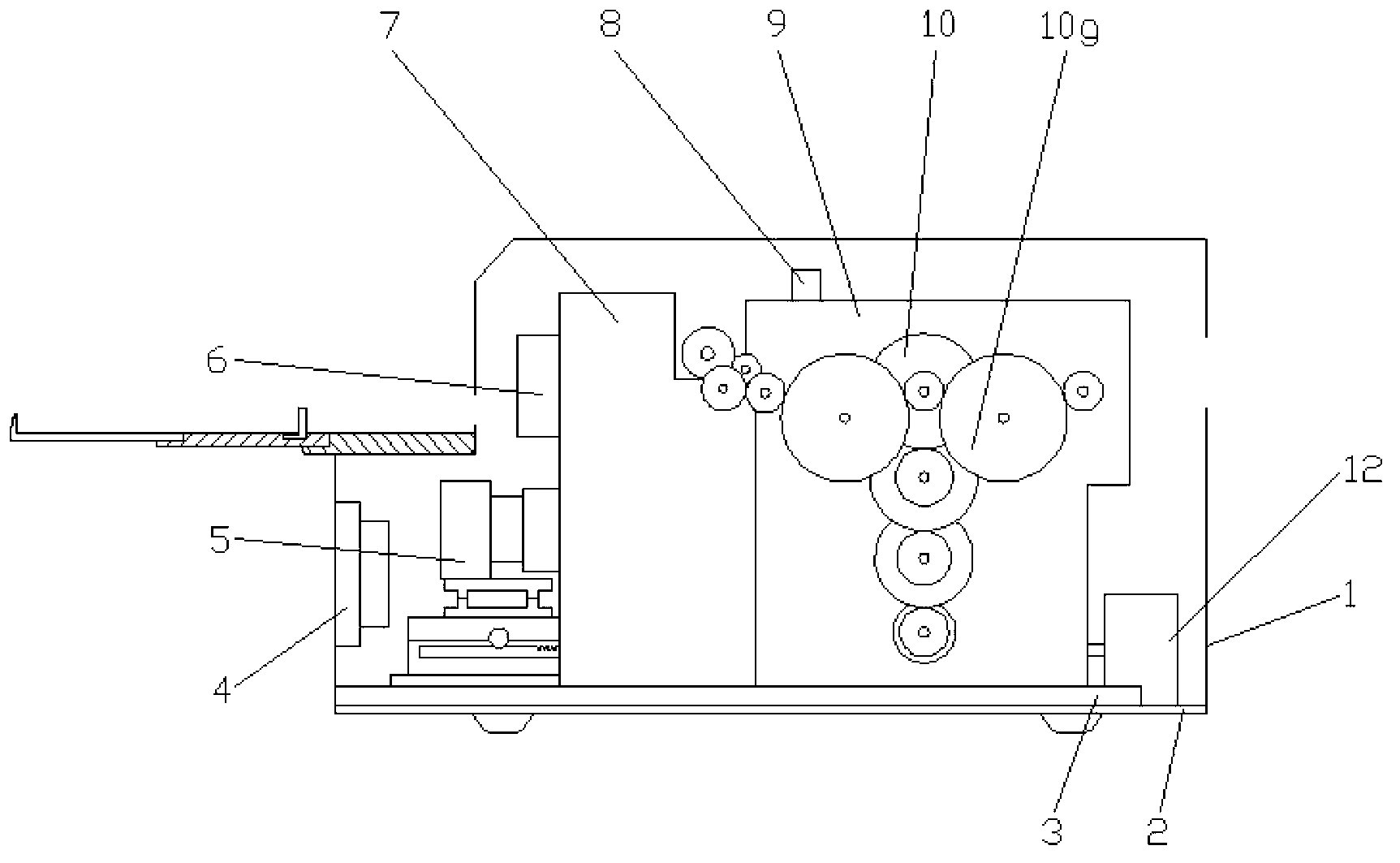

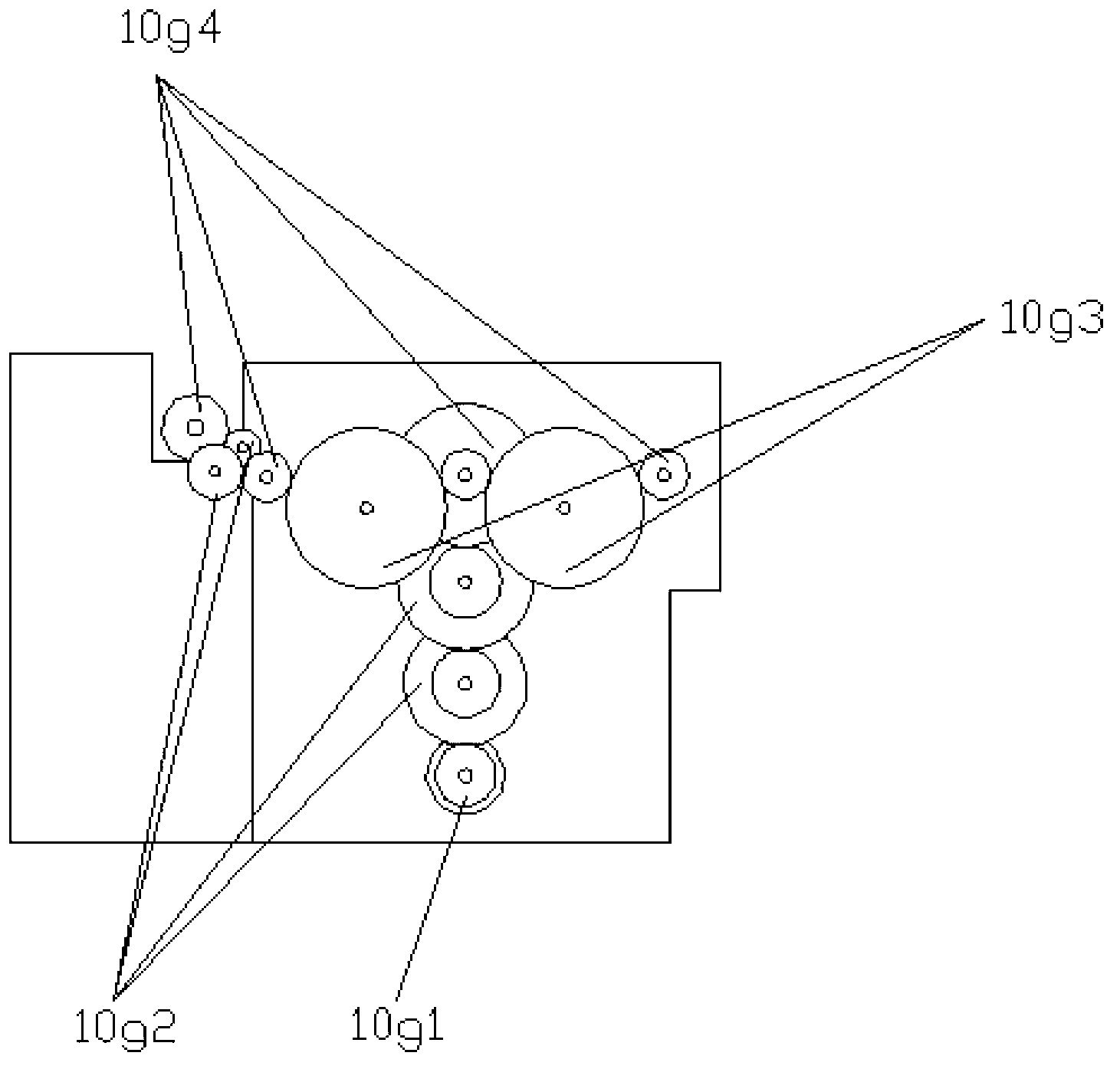

[0027] refer to Figure 1 to Figure 7 As shown, the present invention is an industrial radiation detection film digital device, which includes an automatic film feeding mechanism 6 , an automatic shading mechanism 14 , a digital acquisition module 15 , a housing 1 and a housing bottom plate 2 .

[0028]The automatic film feeding mechanism 6 is fixed on the front side plate 7 , the automatic shading mechanism 14 is fixed on the rear side plate 9 , the cooling device 4 is fixed on the shell 1 , and the digital acquisition module 15 is fixed on the second floor 3 . The heat sink 4 includes a filter screen 4a and a fan 4b. The shell 1 and the shell bottom plate 2 are used as the outer cover of the device, the second floor bottom plate 3 is fixed on the shell bottom plate 2, the digital acquisition module 15 is fixed on the upper part of the second floor bottom p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com